Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

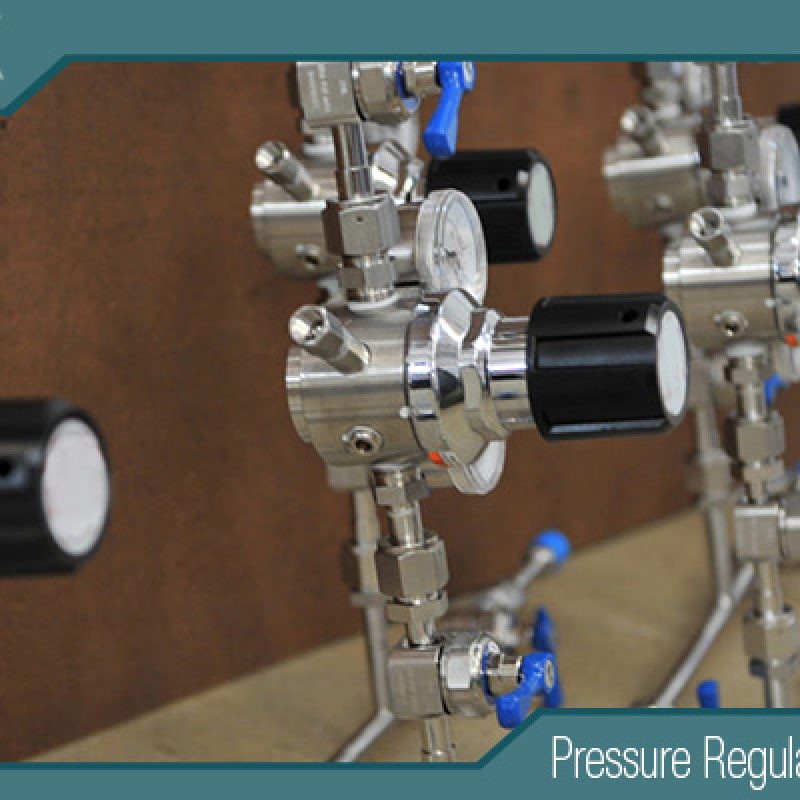

Pressure Relief Valve Manufacturers

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, adjustable hydraulic pressure relief valve, air pressure relief valve suppliers, back pressure regulator manufacturers, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, high flow needle valve manufacturer, high pressure hydraulic needle valve manufacturer, high pressure needle valve manufacturer, high purity valves manufacturers, how often should pressure relief valves be replaced, hydraulic pressure relief valve adjustment, hydraulic pressure relief valve manufacturers, hydraulic pressure relief valve working principle, industrial diaphragm valve manufacturers, needle valve 10000 psi manufacturer, pneumatic actuated ball valve manufacturer, pressure control valve manufacturers, pressure gauge manufacturers, pressure relief valve, pressure relief valve factory, pressure relief valve manufacturers, pressure relief valve market, pressure relief valve supplier, pressure relief valve vs safety relief valve, pressure relief valve vs safety valve, pressure relief valves, pressure relief valves factory, safety relief valve vs pressure relief valve, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer

- No Comments

Pressure Relief Valve Manufacturers

Pressure relief valves (PRVs) are indispensable safety devices engineered to protect equipment and systems from overpressure conditions. These valves automatically release excess pressure when it surpasses a predetermined threshold, thereby preventing potential damage, explosions, or other catastrophic failures. Their importance spans a wide array of industries, including oil and gas, chemical processing, power generation, pharmaceuticals, and manufacturing, where maintaining safe pressure levels is paramount to operational integrity and safety.

The manufacturing of pressure relief valves is a specialized domain that demands precision engineering, strict adherence to industry standards, and a comprehensive understanding of diverse applications. This article delves into the world of pressure relief valve manufacturers, exploring key industry players, market trends, technological advancements, and the challenges and opportunities shaping this critical sector.

Overview of the Pressure Relief Valve Manufacturing Industry

The global pressure relief valve market is propelled by an escalating demand for safety equipment in industrial processes, stringent regulatory mandates, and a heightened focus on preventing accidents and equipment failures. Market research indicates a steady growth trajectory for the PRV industry over the next decade, driven by industrial expansion in emerging economies and modernization efforts in developed regions.

The industry comprises a mix of large multinational corporations and smaller, niche manufacturers. These companies compete on factors such as product quality, reliability, innovation, and the ability to deliver tailored solutions for specific applications. As industrial processes become increasingly complex, the role of PRV manufacturers in ensuring safety and operational efficiency has never been more critical.

Leading Pressure Relief Valve Manufacturers

Below is an overview of some of the most prominent manufacturers in the pressure relief valve industry, recognized for their innovation, quality, and market presence.

- Emerson Electric Co. (Pentair Valves & Controls)

Emerson, through its subsidiary Pentair Valves & Controls, is a dominant force in the valve manufacturing sector. The company offers an extensive range of pressure relief valves, including spring-loaded and pilot-operated designs, serving industries such as oil and gas, power generation, and chemical processing. Emerson is renowned for its engineering excellence and ability to provide solutions for demanding applications.

- Flowserve Corporation

Flowserve is a global leader in fluid motion and control products, with a robust portfolio of pressure relief valves designed for critical applications. Emphasizing reliability and performance, Flowserve caters to industries requiring high-quality safety solutions, such as energy and petrochemicals.

- Curtiss-Wright Corporation

Curtiss-Wright’s Industrial Division specializes in pressure relief valves for both nuclear and non-nuclear applications. The company is celebrated for its adherence to rigorous industry standards and its production of high-quality valves that ensure safety in high-stakes environments like power plants.

- LESER GmbH & Co. KG

LESER, a German manufacturer, focuses exclusively on safety valves, including pressure relief valves. With a reputation for engineering expertise and a customer-centric approach, LESER provides a diverse range of products tailored to various industrial needs.

- Weir Group PLC

Weir Group delivers engineered solutions across multiple sectors, including pressure relief valves for oil and gas, mining, and power generation. Their valves are designed to perform reliably in challenging conditions, reinforcing their standing in the market.

- Alfa Laval AB

Alfa Laval, a Swedish company, excels in providing specialized products for heat transfer, separation, and fluid handling. Their pressure relief valves are crafted for hygienic applications in industries like food, pharmaceuticals, and biotechnology, meeting strict regulatory requirements.

- GE Energy (Baker Hughes)

Baker Hughes, part of GE Energy, offers pressure relief valves tailored for the oil and gas sector. The company focuses on safety and reliability, delivering products suited for harsh and demanding environments.

- IMI plc

IMI is a global engineering group manufacturing pressure relief valves for critical applications in energy, transportation, and industrial sectors. Their solutions are known for precision and durability.

- Crane Co.

Crane’s Fluid Handling segment produces a variety of valves, including pressure relief valves, for industrial and commercial uses. The company combines tradition with innovation to meet modern safety demands.

- Velan Inc.

Velan, a Canadian manufacturer, is recognized for its high-performance valves, including pressure relief valves for power generation, oil and gas, and other industries. Their products are engineered for longevity and efficiency.

Types of Pressure Relief Valves and Applications

Pressure relief valves are available in various designs, each suited to specific applications and operational requirements:

- Spring-Loaded Valves: The most common type, these valves use a spring to keep the valve closed until pressure exceeds the set point, at which point it opens to release excess pressure.

- Pilot-Operated Valves: These utilize system pressure to control the valve’s opening and closing, offering precise regulation for high-pressure scenarios.

- Bellows-Type Valves: Designed for applications requiring isolation from process fluids, such as in corrosive or toxic environments, these valves feature a bellows to protect internal components.

Manufacturers must possess a deep understanding of these applications to design and supply valves that meet the unique needs of each industry, from high-pressure oil pipelines to sterile pharmaceutical processes.

Industry Standards and Regulations

Compliance with industry standards is a cornerstone of pressure relief valve manufacturing, ensuring product safety and reliability. Key standards include:

- ASME Boiler and Pressure Vessel Code: Governs the design, fabrication, and inspection of pressure relief valves, with sections like VIII (pressure vessels) and I (power boilers) being particularly relevant.

- API Standards: The American Petroleum Institute sets standards like API 526 (flanged steel PRVs) and API 527 (seat tightness) for oil and gas applications.

- ISO Standards: Standards such as ISO 9001 (quality management), ISO 14001 (environmental management), and ISO 4126 (safety valves) guide manufacturers in maintaining global benchmarks.

Manufacturers often secure certifications from accredited bodies to validate compliance, enhancing customer trust and enabling market access in regulated industries.

Manufacturing Process and Quality Control

Producing pressure relief valves involves a meticulous process to ensure they perform reliably under critical conditions. Key stages include:

- Design and Engineering: Advanced software and simulations are used to create valves that meet performance criteria and industry standards.

- Material Selection: Materials are chosen for durability, corrosion resistance, and compatibility with process fluids, ranging from stainless steel to specialized alloys.

- Machining and Assembly: Precision machining and careful assembly ensure tight tolerances and proper functionality.

- Testing and Inspection: Valves undergo rigorous tests, such as hydrostatic testing, seat leakage checks, and set pressure verification, to confirm performance.

- Certification and Documentation: Comprehensive documentation, including test reports and material certificates, accompanies each valve to verify compliance and quality.

Stringent quality control at every step ensures that the final product meets the highest safety and reliability standards.

Challenges Faced by Manufacturers

The pressure relief valve manufacturing industry encounters several challenges:

- Increasing Competition: A crowded market requires manufacturers to differentiate through innovation, quality, and superior customer service.

- Evolving Customer Demands: Clients increasingly seek advanced features like remote monitoring and predictive maintenance, pushing manufacturers to adapt.

- Technological Advancements: Continuous investment in R&D is necessary to integrate new technologies and maintain a competitive edge.

- Regulatory Compliance: Keeping pace with evolving regulations and ensuring products meet the latest standards demands significant resources.

Case Studies and Examples

To highlight the critical role of PRVs and their manufacturers, consider these examples:

- Oil and Gas: In this sector, PRVs protect pipelines and storage tanks from overpressure events that could lead to leaks or explosions. Companies like Emerson and Flowserve supply valves designed for extreme conditions, adhering to API standards.

- Pharmaceuticals: Alfa Laval provides sanitary PRVs that prevent contamination in drug manufacturing, meeting stringent hygiene and safety requirements.

- Nuclear Power: Curtiss-Wright manufactures PRVs for nuclear reactors, ensuring safe pressure management under the rigorous standards of the nuclear industry.

These cases underscore the diverse applications and the expertise manufacturers bring to each sector.

Future Outlook

The future of the pressure relief valve industry is shaped by several emerging trends:

- Digitalization and IoT Integration: Smart valves with sensors enable real-time monitoring, data analysis, and predictive maintenance, reducing downtime and enhancing safety.

- Sustainability and Energy Efficiency: Manufacturers are developing eco-friendly valves with lower leakage rates and sustainable materials to support green industrial practices.

- Customization and Flexibility: As industries diversify, demand grows for bespoke solutions tailored to specific conditions, such as high-temperature or corrosive environments.

- Global Market Expansion: Growth in Asia-Pacific and Latin America offers opportunities, though manufacturers must navigate local regulations and build robust distribution networks.

Conclusion

Pressure relief valve manufacturers are pivotal in safeguarding industrial processes, delivering high-quality, innovative products that prevent accidents and ensure operational efficiency. As the industry evolves, these companies must embrace digital transformation, prioritize sustainability, and adapt to diverse customer needs to thrive in a competitive global market. Through their expertise and commitment, PRV manufacturers uphold safety and reliability across critical sectors, reinforcing their indispensable role in modern industry.

For more about the best pressure relief valve manufacturers, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

Stainless Steel Ultra High Purity Mini Butt Weld Mini Tee Reducer MTRW Series Fittings

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases