BSGS Large Flow Specialty Gas Supply Cabinet 3 Cylinder Gas Storage Cabinet Fully Automated PLC Control Bulk Specialty Gas Systems (BSGS) Gas Cabinets

BSGS Large Flow Specialty Gas Supply Cabinet 3 Cylinder Gas Storage Cabinet Fully Automated PLC Control Bulk Specialty Gas Systems (BSGS) Gas Cabinets

Jewellok specializes in fully automatic and semi-automatic GC gas cabinets, BSGS gas cabinets, VMB gas cabinets, TMA gas cabinets, Scrubber tail gas treatment cabinets, gas distribution cabinets, VDB gas cabinets, and VDP gas cabinets, suitable for gases such as SiH4, NF3, NH3, N2O, and HCI.

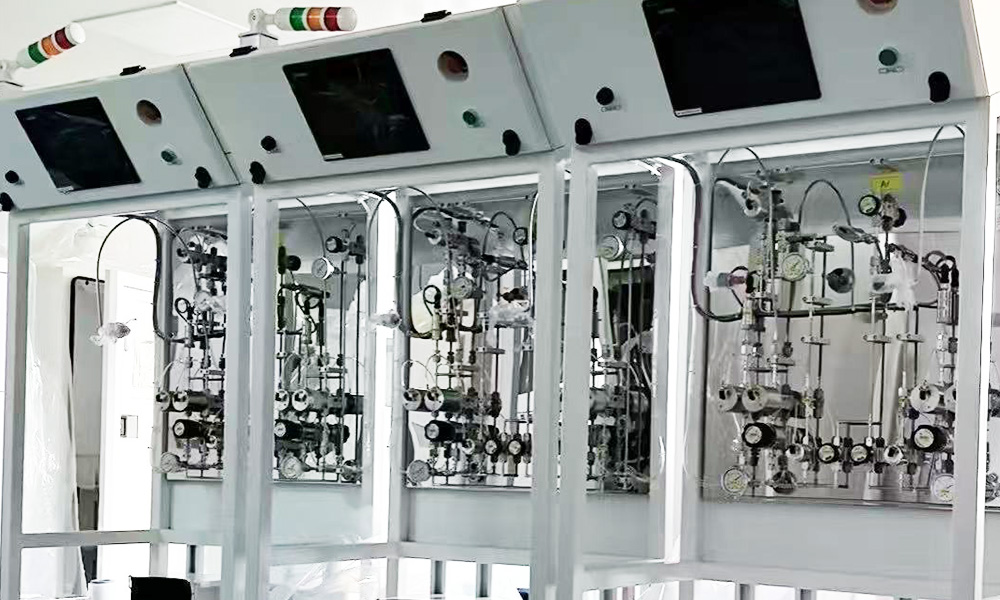

The BSGS Large Flow Specialty Gas Supply Cabinet is an advanced solution for safely managing specialty gases in industries such as semiconductors, LCD manufacturing, and solar energy. Designed to handle toxic, flammable, or corrosive gases, this 3-cylinder gas storage cabinet integrates fully automated Programmable Logic Controller (PLC) technology to ensure precision, safety, and operational efficiency.

Constructed from durable 11-gauge steel with a corrosion-resistant finish, the cabinet measures 42” W x 23” D x 89” H, offering a compact yet robust design. It features large safety-glass windows and self-latching doors for secure access. The cabinet supports three cylinders, accommodating high-flow or ultra-high-flow demands using cylinder bundles, Y-cylinders, or tube trailers, making it versatile for applications like 65nm and 45nm chip production.

The PLC system, paired with an intuitive color touchscreen interface, automates gas delivery, cylinder switching, and nitrogen purging to maintain gas purity and prevent contamination. Safety is prioritized with exhaust sensors, UL-listed sprinkler heads, and optional features like toxic gas monitors, fire sensors, and leak detection systems, ensuring compliance with SEMI-F14 standards.

The BSGS cabinet enhances operational efficiency by reducing manual intervention by up to 30%, minimizing pressure fluctuations, and achieving 99.999% uptime reliability. Automated purge and leak-check functions, along with remote monitoring, streamline operations and enhance safety. Optional components like flow meters, scales, and heating blankets allow customization for precise gas management.

This system is ideal for critical environments requiring consistent, high-purity gas delivery, offering a reliable and customizable solution for modern industrial needs.

Technical Data

| Model | JW-300-BSGS |

| Specification | W800*D633*H2172 |

| Special gas cabinet size | Control power supply: 220VAC, 50HZ, 500W, heating power supply: 220VAC, 50HZ, 1-6KW |

| Control cabinet power supply | PN2,1/4”MVCR |

| Purge | HPN2,1/4”MVCR |

| High pressure holding | GN2.1/4” MVCR |

| Vacuum | 1/2” MVCR |

| VENT drain pipe | CDA driver, 1/4″ SWG |

| Pneumatic air source | OD 150MM, silane 810m/hr; others 204m3/hr |

| Cabinet ventilation | Automatic switching, automatic purging, explosion-proof and anti-leaving cabinet, explosion-proof self-locking door, explosion-proof glass observation window, leakage alarm, remote cut-off, negative pressure alarm |

| Operation interface | 10″ color touch screen |

Features:

Functionality: Specially designed for flammable, toxic, or corrosive gases such as hydrogen, ammonia, and chlorine.

Applications: Critical environments such as semiconductor fabs, special gas labs, and research institutions with stringent safety requirements.

Control Method: Fully automated with PLC control, including gas sensors, exhaust fan interlocks, fire control systems, and access control.

Safety Features:

1)Explosion-proof electrical components

2)Ventilation and exhaust control

3)Combustible/toxic gas detection and alarm interlocks

4)Emergency shut-off valves

5)Optional fire suppression or gas purification modules

Optional

*UV/IR Flame Detector

*Cylinder Shutboy

*Panel heating

*Ethernet communication module

*Weight Scale

*Excess Flow Switch