High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

Product Details

Place of Origin: Guangdong, China (Mainland)

Brand Name: Jewellok

Certification: CE

Model Number: JW100

Payment & Shipping Terms

Minimum Order Quantity: >=1 Sets

Price: Negotiable

Packaging Details: Export packing

Supply Ability:5000 Set/Sets per Week

|

Max Inlet Pressure:

|

2200, 3000 Psig

|

Outlet Pressure Range:

|

0~25, 0~50, 0~100, 0~150 , 0~250psig

|

|

Working Temperature:

|

-40° F ~+165° F(-40°C+74°C)

|

Cv:

|

0.14

|

|

Valve Seat:

|

PU, PTFE ,FCTFE

|

Body Material:

|

316L

|

|

Diaphragms:

|

316L

|

Pressure Gauge Size:

|

2″

|

|

Port:

|

SHENZHEN

|

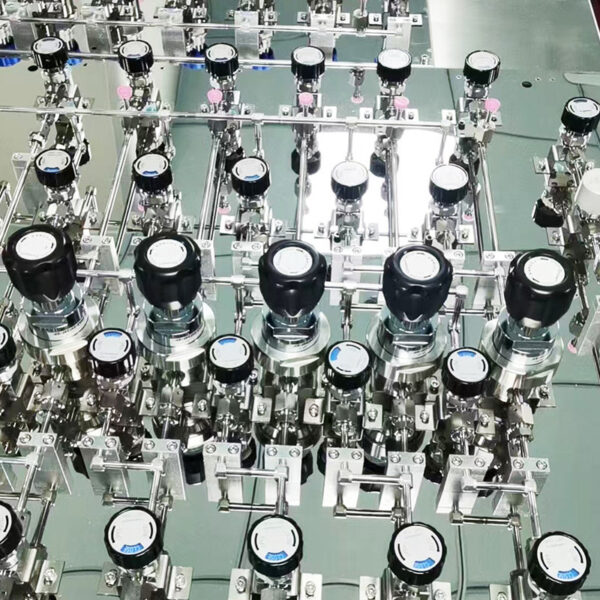

A high-pressure high-flow specialty gas control panel with diaphragm valves is a critical component in industries requiring precise gas delivery, such as semiconductor manufacturing, pharmaceuticals, and chemical processing. Designed to handle high-pressure gases while ensuring safety and accuracy, these panels incorporate diaphragm valves for superior leak-tightness and contamination control.

The panel’s core feature is the diaphragm valve, typically constructed from stainless steel or Hastelloy, which isolates the gas stream from the environment, minimizing leaks and ensuring purity. These valves offer low internal volume and excellent flow characteristics, making them ideal for high-flow applications. The panel integrates pressure regulators, gauges, and flow meters to maintain consistent output under varying pressures, often exceeding 3000 psi.

Safety is prioritized with features like pressure relief valves and robust materials to withstand corrosive or reactive gases. The modular design allows customization for specific gases, such as argon, nitrogen, or specialty mixtures, ensuring compatibility and reliability. Automated controls and remote monitoring capabilities enhance operational efficiency.

Applications include gas chromatography, laser systems, and cleanroom environments. Regular maintenance, including valve inspections and leak tests, ensures long-term performance. These panels deliver precision, safety, and durability for demanding industrial gas management needs.

1) Max. Inlet Pressure: 3000, 2200Psi

2) Max. Outlet Pressure: 25, 50, 100, 150, 0~250Psi

3)Working Temperature: -40℃~74℃(-40℉~165℉)

4) Leakage rate: 2 x 10-8 atm.cc/sec He

5)Cv: 0.08

Design Features

1) Pressure regulator for special gas

2) Equipped relief pressure valve

3)Pressure regulator and pipe through the pressure test and leakage test

4)2″ stainless steel pressure gauge, reading clearly

5) The knob of diaphragm valves with on/off logo.

|

Material List

|

|||

|

Body material

|

Stainless steel 316L

|

||

|

Valve Seat

|

PU, PTFE, PCTFE

|

||

|

Diaphragm

|

Stainless steel 316L

|

||

|

Inlet connection

|

1/4″ NPT (F)

|

||

|

Outlet connection

|

1/4″ NPT (F)

|

||

ORDERING INFORMATION

| ORDERING INFORMATION | ||||||||

| JW100 | 1 | 1 | 1 | S | H | 1 | 1 | -N2 |

| Series | Function Options | Outlet Connection | Inlet Connection | Body Material | Input

Pressure |

Outlet

Pressure |

Gauge | Gas Option |

| JW100 Series Semi-automatic Changeover Device | 1.With emptying, purging distribution function | 1:1/4”NPT(F) | 1:1/4″Weldmg | S:stainless | H:3000psi | 1:25psi | 1:MPa | Blank: None |

| 2.Wrthout Emptying, purging distribution function | 2:1/4”Tube fitting | 2:1/4”NPT(M) | steel | M:2200psi | 2:50psi | 2:Bar/psi | N2:nitrogen | |

| 3.Emptying. purging distnbuUon+pressure sensor | 3:3/8”NPT(F) | 3:3/8”Melding | C:nickel plated | L:1000psi | 3:100psi | 3:psi/KPa | O2:oxygen | |

| 4.With pressure sensor | 4:3/8”Tube fitting | 4:3/8”NPT(M) | brass | O: Other | 4:150psi | 4:Other | H2:hydrogen | |

| 5:Other | 5:1/2”NPT(F) | 5:1/2”Melding | 5:250psi | C2H2:acetylene | ||||

| 6:1/2”Tube fitting | 6:1/2”NPT(M) | 6:Other | CH4:methane | |||||

| 7:Other | 7:1/4”Tube fitting | Ar:argon | ||||||

| 8:3/8″Tube fitting | He:helium | |||||||

| 9:1/2″Tube fitting | Air:air | |||||||

| 10:Other | ||||||||