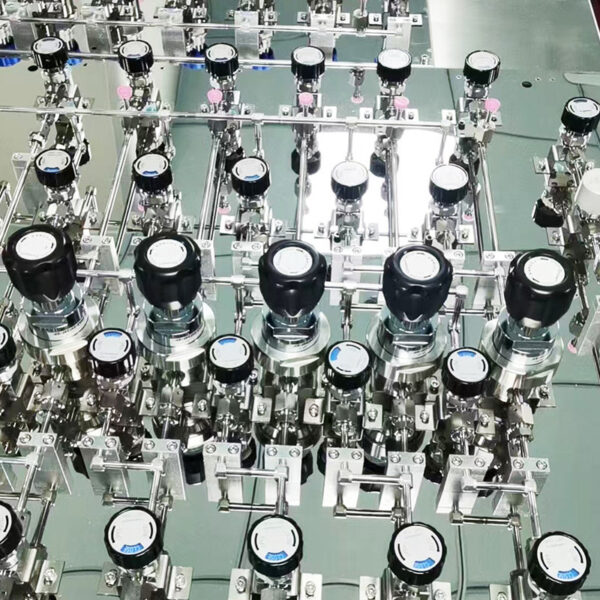

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

Product Details

Place of Origin: Guangdong, China (Mainland)

Brand Name: Jewellok

Certification: CE

Model Number: JW-400

Payment & Shipping Terms

Minimum Order Quantity: 1 – 9 Pieces

Price: Negotiable

Packaging Details: Each piece with a PP bag first, then put in a small box, outside is in carton.

Supply Ability: 5000 Piece/Pieces per Week

|

Material:

|

316L SS

|

Maximum Inlet Pressure:

|

3000, 2200, 500PSI

|

|

Output Pressure:

|

0-25,0-50,0-100, 0-250, 0-500PSI

|

Working Temperature:

|

-23~+74 Deg C

|

|

Applied Gas:

|

Pure Gases, Standard Gases, Corrosive Gases And So On

|

Bonnet Material:

|

Ss316L

|

|

Seat:

|

PCTFE

|

Spring:

|

Ss316L

|

|

O-ring:

|

Viton

|

Strainer:

|

316L (um)

|

|

Port:

|

Shenzhen

|

A high purity gas cylinder semi-automatic changeover regulator panel is a critical system used in industries requiring uninterrupted, high-purity gas supply, such as semiconductor manufacturing, laboratories, and medical facilities. This panel ensures a continuous gas flow by automatically switching between gas cylinders when one is depleted, maintaining operational efficiency and safety.

The system consists of two or more high-purity gas cylinders connected to a regulator panel equipped with pressure regulators, valves, and gauges. The semi-automatic changeover mechanism monitors the pressure in the active cylinder. When the pressure drops below a set threshold, the system seamlessly switches to a full cylinder without interrupting the gas supply. This process is vital for applications where consistent gas purity and flow are essential, such as in gas chromatography or cleanroom environments.

The regulator panel is designed to handle high-purity gases like nitrogen, helium, or argon, ensuring minimal contamination. It typically includes high-precision regulators to maintain stable output pressure and filters to remove impurities. The semi-automatic feature allows operators to replace empty cylinders without shutting down the system, though manual intervention may be required to reset or replace cylinders.

Key components include stainless steel or brass fittings for corrosion resistance, pressure gauges for monitoring, and safety relief valves to prevent over-pressurization. The panel is often equipped with alarms or indicators to signal cylinder depletion or system issues, enhancing reliability.

These systems are compact, user-friendly, and customizable to meet specific gas requirements. Regular maintenance, such as checking for leaks and calibrating regulators, ensures optimal performance. By automating cylinder changeovers, the panel reduces downtime, improves safety, and ensures a consistent supply of high-purity gas, making it indispensable in precision-driven industries.

In summary, a high purity gas cylinder semi-automatic changeover regulator panel is a reliable solution for maintaining uninterrupted gas supply, ensuring operational continuity and safety in critical applications.

JW-400 is suitable for secondary pipeline, suitable for controlling gas flow. Max. inlet pressure 20.7Mpa (300PSI), resistance corrosive, clean workshop test, it is suitable for Laboratory, gas anysis etc high purity gas.

|

Maximum Inlet Pressure

|

500,3000psig

|

||

|

Outlet Pressure Ranges

|

0~25, 0~50, 0~50,0~250,0~500psig

|

||

|

Safety test pressure

|

1.5 times maximum inlet pressure

|

||

|

Operating Temperature

|

-40°F to 165°F / -40°c to 74°c

|

||

|

Leakage Rate Against Atmosphere

|

2*10-8atm cc/sec he

|

||

|

Cv value

|

0.14

|

||

Material of Parts

|

Body

|

316L

|

||

| Bonnet |

316L

|

||

|

Diaphragm

|

316L

|

||

|

Strainer

|

316L(10mm)

|

||

|

Seat

|

PCTFE,PTEE,Vespel

|

||

|

Spring

|

316L

|

||

|

Plunger valve core

|

316L

|

||

|

Series

|

inlet connection

|

Outlet connection

|

Body

|

Inlet pressure

|

outlet pressure

|

Gauge

|

N2

|

|

JW-400

|

1:6mm barb fitting

|

1: 1/4″ welding

|

s: ss316

|

H:1000PSI

|

1:25PSI

|

1:Mpa

|

O2

|

|

|

2:1/4“O.D.

|

2: 3/8″welding

|

C:nickel plated brass

|

M:500psi

|

2:50PSI

|

2:bar/PSI

|

H2

|

|

|

3:8mm barb fitting

|

5.1/2″ welding

|

|

L:300PSI

|

3:100PSI

|

3:PSI/kpa

|

C2H2

|

|

|

4:3/8″O.D.

|

7: 1/4″O.D.

|

|

|

4:150PSI

|

|

CH4

|

|

|

5:10mm barb fitting

|

8:3/8″O.D.

|

|

|

5:250PSI

|

|

AR

|

|

|

6:1/2″O.D.

|

9: 1/2″O.D.

|

|

|

|

|

HE

|

|

Air

|

Customized manufacturing are supported, so you can contact us for your custom specialty gas delivery system.