Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

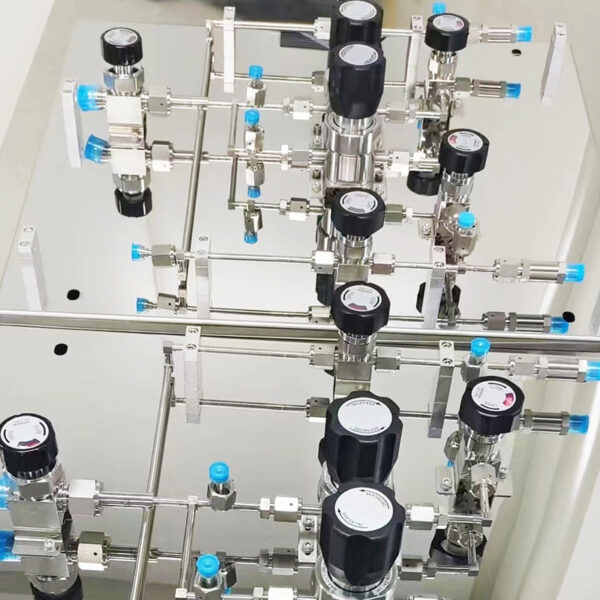

A gas manifold system is critical for safely and efficiently distributing gases like hydrogen, argon, oxygen, and propane in industrial, medical, or laboratory settings. These systems regulate gas flow from multiple cylinders to a single output, ensuring a continuous supply through a changeover system with valves.

Hydrogen Manifold System: Hydrogen, a highly flammable gas, requires robust manifold systems with high-pressure regulators and non-sparking materials. Valves control flow and prevent leaks, while pressure gauges monitor safe levels. The changeover system automatically switches to a backup cylinder when the primary one depletes, ensuring uninterrupted supply.

Argon Gas Manifold System: Argon, commonly used in welding and metal fabrication, demands precise flow control. The manifold includes pressure regulators, isolation valves, and check valves to prevent backflow. The changeover system maintains a steady supply, critical for processes like TIG welding, where consistent argon flow is essential.

Oxygen Manifold System: Oxygen manifolds support applications like medical oxygen delivery or industrial cutting. These systems use corrosion-resistant materials due to oxygen’s reactive nature. Valves ensure precise delivery, and the changeover system prevents supply interruptions, vital for critical applications like patient care.

Propane Gas Manifold System: Propane manifolds serve heating or fuel applications. They include safety relief valves and regulators to manage high-pressure gas. The changeover system ensures seamless transitions between cylinders, maintaining consistent propane flow for burners or furnaces.

Gas Manifold Changeover System: The changeover system is the core of these manifolds, using automatic or manual valves to switch between primary and backup cylinders. It includes pressure sensors, alarms, and shut-off valves for safety, minimizing downtime and ensuring operational efficiency.

In summary, these manifold systems, equipped with specialized valves and changeover mechanisms, provide safe, reliable, and continuous gas supply tailored to each gas’s unique properties.

Product Details

Place of Origin: Guangdong, China (Mainland)

Brand Name: Jewellok

Certification: CE

Model Number: JW-400

Payment & Shipping Terms

Minimum Order Quantity: >=1 Sets

Price: Negotiable

Packaging Details: Export packing

Supply Ability: 5000 Set/Sets per Week

Highlight:

gas control panel,

automatic switchover manifold

|

Max Inlet Pressure:

|

2200, 3000 Psig

|

Outlet Pressure Range:

|

0~25, 0~50, 0~100, 0-150, 0~200 Psi

|

|

Working Temperature:

|

-40° F ~+165° F(-40°C+74°C)

|

Cv:

|

0.14

|

|

Valve Seat:

|

FCTFE

|

Body Material:

|

SS 316L

|

|

Diaphragms:

|

316L

|

Port:

|

SHENZHEN

|

Product Features

*Equipped Jewellok pressure regulator and high pressure ball valve

*Pressure regulator and pipe through the pressure test and leakage test

*Wall installation, easy to use and safe

*2″ stainless steel pressure gauge, reading clearly

Product Specifications

Typical applications

1) Laboratory

2) Gas Chromatography

3) Gas Laser

4)Tested instrumentation

Packing & Delivery

|

Packaging

|

|

|

Size

|

Decided on the product

|

|

Weight22

|

2KGS |

|

Packaging Details

|

Export packing or according customer’s request.

|

Jewellok Is Specialty Gas Automatic Changeover Manifold Manufacturer And Supplier In China,Manufacturing Semi Automatic And Automatic Stainless Steel High Purity Oxygen Nitrogen Helium Argon Gas Changeover Manifold, Automatic Gas Switchover System, Automatic Non-Electric Gas Cylinder Changeover Systems, Specialty Gas Fully Automatic Changeover Manifolds And So On.