Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

In the semiconductor industry, the safe storage and precise delivery of high-purity, high-pressure specialty gases are critical for maintaining production quality and safety. Gas bottle storage cabinets and gas pressure regulating cabinets play essential roles in ensuring these gases are handled efficiently and securely.

Gas Cylinder Storage Cabinets

Specialty gas cylinders, containing high-purity gases like nitrogen, argon, or hydrogen, require robust storage solutions. Gas cylinder storage cabinets are designed to securely house these cylinders, protecting them from environmental factors and unauthorized access. Constructed from durable materials like stainless steel, these cabinets feature ventilation systems to prevent gas accumulation, fire-resistant designs, and secure locking mechanisms. They are engineered to comply with strict safety standards, minimizing risks of leaks or accidents. Proper labeling and organization within the cabinet ensure easy identification and access, critical for high-paced semiconductor manufacturing environments.

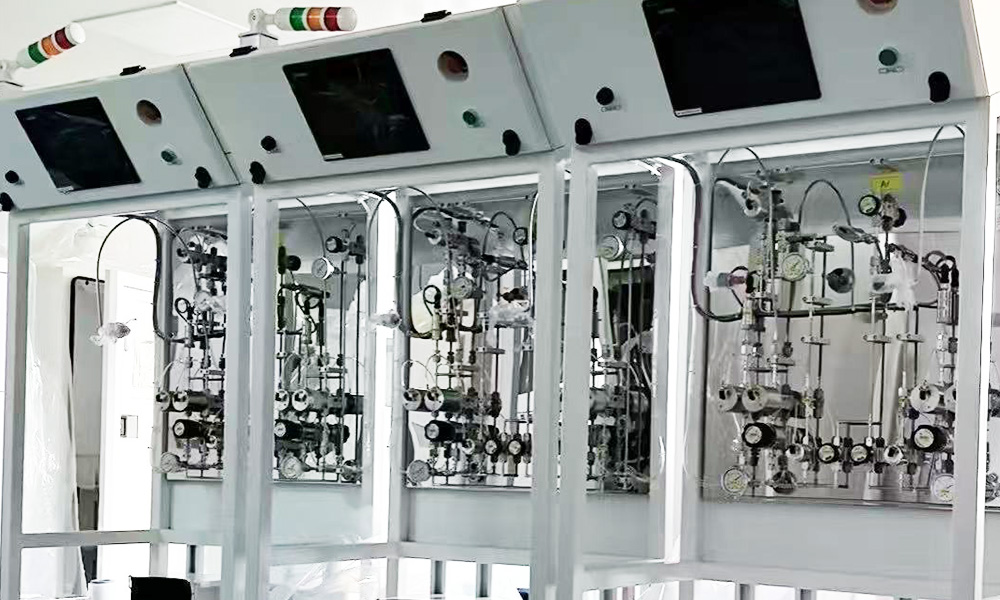

Gas Pressure Regulating Cabinets

Gas pressure regulating cabinets are vital for delivering specialty gases at precise pressures to semiconductor equipment. These cabinets house regulators, valves, and monitoring systems to control gas flow and pressure with high accuracy. Equipped with advanced sensors and alarms, they detect leaks or pressure deviations, ensuring operational safety and consistency. The cabinets are designed for cleanroom compatibility, using materials that prevent contamination of high-purity gases. Automated controls and remote monitoring capabilities further enhance efficiency, reducing downtime in production processes.

Together, these cabinets ensure the safe storage and controlled delivery of specialty gases, supporting the semiconductor industry’s demand for precision and reliability. By integrating advanced safety features and cleanroom-compliant designs, they contribute to efficient, high-quality chip manufacturing while adhering to stringent industry regulations.

Technical Data

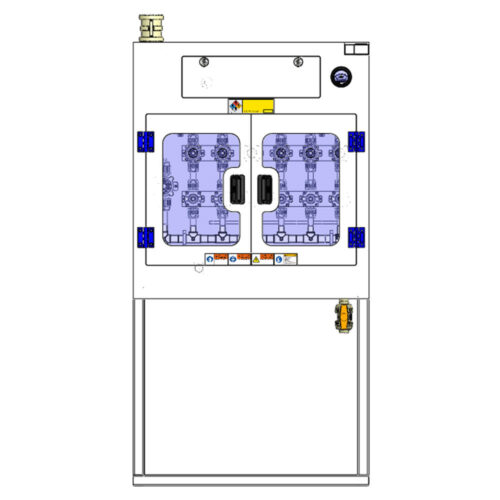

| Model | JW-300-GR |

| Specification | Single bottle/double bottle |

| Special gas cabinet size | Double bottle: W800*D520*H1957, single bottle: W500*D520*H1957 |

| Control cabinet power supply | Control power supply: 220VAC, 50HZ, 500W, heating power supply: 220VAC, 50HZ, 1-6KW |

| Purge | PN2,1/4”MVCR |

| High pressure holding | HPN2,1/4”MVCR |

| Vacuum | GN2.1/4” MVCR |

| VENT drain pipe | 1/2” MVCR |

| Pneumatic air source | CDA driver, 1/4″ SWG |

| Operation interface | 7″ color touch screen/buttons |

Optional

*Weight Scale

*Panel heating

*Excess Flow Switch

*Ethernet communication module

*CGA Guarder