Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

Jewellok specializes in fully automatic and semi-automatic GC gas cabinets, BSGS gas cabinets, VMB gas cabinets, TMA gas cabinets, Scrubber tail gas treatment cabinets, gas distribution cabinets, VDB gas cabinets, and VDP gas cabinets, suitable for gases such as SiH4, NF3, NH3, N2O, and HCI.

Ultra High Purity (UHP) Trimethylaluminum (TMA) gas cabinets are specialized systems designed for safe and efficient delivery of TMA, a critical precursor in semiconductor manufacturing. TMA, a highly reactive organometallic compound, is used in processes like Atomic Layer Deposition (ALD) and Metal-Organic Chemical Vapor Deposition (MOCVD) to deposit thin films, such as aluminum oxide, for advanced microelectronics.

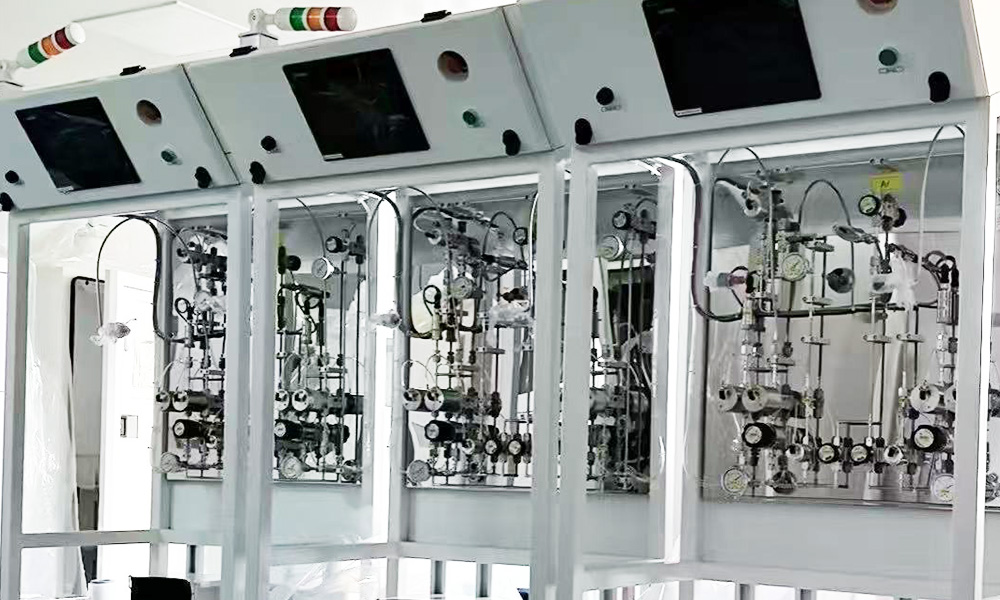

The TMA gas cabinet ensures precise, contamination-free delivery of this pyrophoric liquid, which vaporizes into a gas for use. The system is engineered to meet stringent semiconductor industry standards, minimizing impurities that could compromise wafer quality. Key components include a stainless-steel cabinet, a liquid delivery system, high-purity valves, and advanced sensors. The cabinet is designed for safety, incorporating features like leak detection, automated shut-off valves, and exhaust systems to handle TMA’s flammability and reactivity.

The liquid delivery mechanism typically involves a bubbler or direct liquid injection system, where TMA is vaporized using a carrier gas (e.g., nitrogen or argon) or heated to produce a stable gas flow. Precision control systems regulate temperature, pressure, and flow rate to ensure consistent delivery to deposition tools. The cabinet’s UHP construction, with electropolished surfaces and VCR fittings, prevents contamination from particles or trace metals.

TMA gas cabinets are equipped with advanced monitoring systems, including pressure transducers and mass flow controllers, to maintain process reliability. Regular maintenance and strict handling protocols are essential due to TMA’s sensitivity to air and moisture. These systems are integral to semiconductor fabrication facilities, enabling high-yield production of integrated circuits and optoelectronic devices.

In summary, UHP TMA gas cabinets are vital for delivering high-purity TMA in semiconductor manufacturing. Their robust design ensures safety, precision, and reliability, supporting the production of cutting-edge microelectronics.

Technical Data

| Model | JW-400-TMA |

| Specification | W800*D633*H2172 |

| Special gas cabinet size | Control power supply: 220VAC, 50HZ, 500W, heating power supply: 220VAC, 50HZ, 1-6KW |

| Control cabinet power supply | PN2,1/4”MVCR |

| Purge | HPN2,1/4”MVCR |

| High pressure holding | GN2.1/4” MVCR |

| Vacuum | 1/2” MVCR |

| VENT drain pipe | CDA driver, 1/4″ SWG |

| Pneumatic air source | OD 150MM, silane 810m/hr; others 204m3/hr |

| Cabinet ventilation | Automatic switching, automatic purging, explosion-proof and anti-leaving cabinet, explosion-proof self-locking door, explosion-proof glass observation window, leakage alarm, remote cut-off, negative pressure alarm |

| Operation interface | 10″ color touch screen |

Optional

*UV/IR Flame Detector

*Cylinder Shutboy

*Panel heating

*Ethernet communication module

*Weight Scale

*Excess Flow Switch