Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Series Single Stage Backpressure Regulator: A Comprehensive Guide

- Pressure Regulator Valve Manufacturer

- 2 stage propane regulator vs single stage, back pressure regulator diagram, back pressure regulator valve, back pressure regulator working principle, back pressure regulators in series, difference between dual and single-stage regulator, dual stage vs single stage regulator, high pressure back pressure regulator, series single stage backpressure regulator, single stage gas regulator, single stage gas regulator China, single stage gas regulator manufacturer, single stage gas regulator supplier, single stage high pressure gas regulators, single stage high pressure gas regulators in india, single stage high pressure regulator, single stage high purity regulator, single stage pressure regulator, single stage propane regulator, single stage propane regulator china, single stage propane regulator manufacturer, single stage regulator diagram, single-stage regulator

- No Comments

Series Single Stage Backpressure Regulator: A Comprehensive Guide

Fluid control systems are the backbone of numerous industrial processes, ensuring that gases and liquids flow efficiently and safely under precise conditions. Among the essential components in these systems are backpressure regulators, devices designed to maintain a specific pressure upstream of themselves. This article delves into the world of series single stage backpressure regulators, exploring their definition, functionality, applications, and how to select and maintain them effectively. Spanning approximately 2000 words, this guide provides a thorough understanding of these vital instruments and their role across various industries.

Introduction

In fluid control systems, maintaining consistent pressure is critical for operational efficiency, equipment protection, and safety. A backpressure regulator serves this purpose by controlling the pressure upstream of the device, ensuring it remains at a predetermined set point. Unlike pressure-reducing regulators, which lower the pressure downstream for safe delivery to equipment, backpressure regulators focus on the pressure before the regulator, releasing excess pressure or restricting flow as needed.

The term series single stage backpressure regulator refers to a specific category of these devices, where “single stage” denotes a straightforward, direct-acting design, and “series” typically indicates a product line offering multiple models with varying specifications. These regulators are indispensable in applications requiring reliable upstream pressure control without the complexity of multi-stage systems. This article will explore their features, how they work, their applications across industries, and practical considerations for selection and maintenance.

What Are Single Stage Backpressure Regulators?

A single stage backpressure regulator operates with a simple, direct mechanism to maintain upstream pressure. The term “single stage” distinguishes it from multi-stage regulators, which use multiple steps to adjust pressure. In the context of backpressure regulators, “single stage” means the device responds directly to upstream pressure changes without intermediate adjustments, making it a streamlined solution for many systems.

Advantages of Single Stage Design

Simplicity: With fewer moving parts, single stage regulators are easy to install, operate, and maintain.

Cost-Effectiveness: Their straightforward design reduces manufacturing and maintenance costs, making them an economical choice.

Reliability: Fewer components mean fewer points of potential failure, enhancing durability in consistent pressure environments.

Limitations

Precision: Single stage regulators may not offer the fine-tuned control of multi-stage systems, leading to minor pressure fluctuations.

Application Scope: They are best suited for systems where exact precision is less critical, and moderate pressure stability is acceptable.

This simplicity makes single stage backpressure regulators a popular choice in industries where reliability and affordability outweigh the need for ultra-precise pressure regulation.

Understanding the “Series” Concept

In the context of series single stage backpressure regulators, “series” typically refers to a product line or family of regulators designed with a common single stage mechanism but varying specifications to meet diverse needs. Manufacturers often develop such series to provide options tailored to different pressure ranges, flow capacities, and fluid types.

Examples of a Series

Imagine a hypothetical “BPR-100 Series” of single stage backpressure regulators:

BPR-100L: Designed for low-pressure applications (e.g., 0-50 psi), ideal for delicate processes.

BPR-100M: A medium-pressure model (e.g., 50-150 psi), suitable for general industrial use.

BPR-100H: A high-pressure variant (e.g., 150-500 psi), built for demanding systems like oil and gas extraction.

Within this series, each model shares the same core design but differs in size, materials, or capacity, allowing users to select the most appropriate regulator for their specific application. This versatility is a key advantage, as it ensures compatibility across a wide range of operational requirements.

How Does a Single Stage Backpressure Regulator Work?

To appreciate the value of a series single stage backpressure regulator, it’s essential to understand its working principle. These regulators maintain upstream pressure through a balance of mechanical forces, responding dynamically to changes in the system.

Core Components

Diaphragm or Piston: Senses the upstream pressure and moves in response to changes.

Spring: Provides a counterforce, set to the desired pressure level (the set point).

Valve Seat and Plug: Controls the flow by opening or closing to adjust pressure.

Operating Mechanism

Pressure Below Set Point: When upstream pressure is lower than the spring’s set force, the diaphragm or piston pushes the valve closed. This restricts flow out of the system, allowing pressure to build upstream.

Pressure Above Set Point: If upstream pressure exceeds the set point, the increased force overcomes the spring, moving the diaphragm or piston to open the valve. Excess pressure is released downstream, stabilizing the upstream pressure.

Equilibrium: The regulator continuously adjusts the valve position to maintain the upstream pressure at the set point, achieving a dynamic balance.

Visualization

Picture a cross-section of the regulator: a spring-loaded diaphragm sits above a valve seat, connected to a plug. As pressure acts on the diaphragm, it compresses or relaxes the spring, shifting the plug to regulate flow. This elegant mechanism ensures consistent upstream pressure with minimal complexity.

Applications Across Industries

The versatility of series single stage backpressure regulators makes them invaluable in numerous sectors. Their ability to maintain upstream pressure protects equipment, optimizes processes, and enhances safety. Below are key applications:

1. Chemical Processing

Use: Maintaining constant pressure in reactors to ensure optimal reaction conditions.

Example: In a polymer production facility, a regulator prevents pressure drops that could disrupt the reaction, ensuring product quality.

2. Oil and Gas

Use: Controlling wellhead pressure during extraction to prevent equipment damage and ensure safe operation.

Example: A high-pressure model from a series stabilizes pressure at an offshore drilling site, protecting downstream pipelines.

3. Pharmaceuticals

Use: Regulating pressure in sterilization or fermentation equipment to maintain sterile conditions.

Example: During autoclave operation, a regulator ensures consistent pressure for effective sterilization of medical tools.

4. Water Treatment

Use: Managing pressure in filtration systems to protect membranes and optimize water flow.

Example: In reverse osmosis plants, a regulator maintains upstream pressure to prevent membrane damage and ensure efficient purification.

These examples highlight how a series of regulators, with models tailored to specific pressure and flow needs, can address diverse industrial challenges effectively.

Selecting the Right Series Single Stage Backpressure Regulator

Choosing the appropriate regulator from a series requires careful consideration of system requirements. Here are the key criteria:

1. Pressure Range

Ensure the regulator’s set point range matches the system’s operating pressure (e.g., a 0-100 psi model for a 75 psi requirement).

2. Flow Rate

Match the regulator’s flow capacity to the system’s maximum flow to avoid bottlenecks or insufficient control.

3. Fluid Compatibility

Select materials (e.g., stainless steel for corrosive fluids, brass for non-reactive gases) that won’t degrade or react with the fluid.

4. Temperature Range

Verify the regulator can withstand the system’s operating temperature (e.g., -20°C to 150°C).

5. Port Size and Type

Ensure the regulator’s inlet and outlet ports align with the system’s piping for seamless integration.

6. Accuracy and Stability

Assess the application’s tolerance for pressure fluctuations; single stage regulators suit moderate stability needs.

Practical Selection Example

For a chemical reactor operating at 80 psi with corrosive liquids, you might choose a stainless steel model from a series (e.g., BPR-100M) rated for 50-150 psi, ensuring compatibility and performance.

Installation and Maintenance Best Practices

Proper installation and upkeep are crucial to maximize the lifespan and effectiveness of a series single stage backpressure regulator.

Installation Guidelines

Orientation: Install as per manufacturer instructions (e.g., vertical or horizontal) to ensure proper diaphragm movement.

Piping Support: Secure upstream and downstream piping to prevent stress on the regulator body.

Pre-Installation Check: Verify the set point and clean the system to avoid debris clogging the valve.

Maintenance Tips

Regular Inspection: Check for leaks, corrosion, or wear on the diaphragm and valve seat.

Cleaning: Remove and clean components if exposed to contaminants, using compatible solvents.

Component Replacement: Replace worn diaphragms or springs to restore performance.

Calibration: Periodically adjust the spring tension to maintain the desired set point.

Following these practices ensures reliable operation and prevents costly downtime.

Conclusion

Series single stage backpressure regulators are vital tools in fluid control, offering a simple yet effective solution for maintaining upstream pressure across diverse applications. Their single stage design provides cost-effective reliability, while the series concept ensures a range of models to suit specific needs—from low-pressure chemical processes to high-pressure oil extraction. By understanding their working principles, applications, and selection criteria, users can harness their full potential to enhance system performance and safety. Whether in pharmaceuticals, water treatment, or beyond, these regulators prove their worth as adaptable, indispensable components in modern industry.

For more about series single stage backpressure regulator: a comprehensive guide, you can pay a visit to Jewellok at https://www.jewellok.com/understanding-series-single-stage-backpressure-regulators-how-they-work-and-why-theyre-essential/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

JR1300 Series Ultra High Purity Single Stage Regulator High Flow Line Regulator For Ultra High Purity Intermediate Flow

-

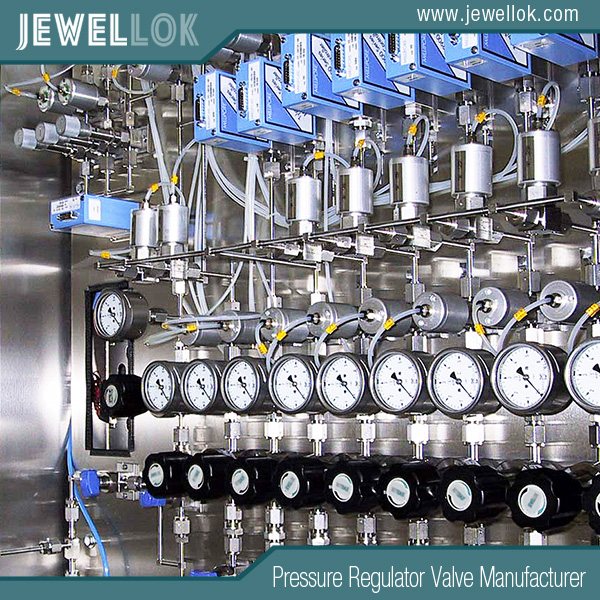

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

Line And Panel Mounting Adjustable Low Pressure Propane And Nitrogen Pressure Regulator JSR-3L & JSR-3LP Series

-

Manual Gas Rack High Purity Gas Delivery Systems JW-100-GR

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

764LR Stainless Steel 316 Reducing Tee UHP Fitting Automatic Buttweld Reducing Tee