Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Single-Stage High-Pressure Nitrogen Cylinder Gas Pressure Regulator Manufacturers in Taiwan

- Pressure Regulator Valve Manufacturer

- best specialty gas cabinet companies in taiwan, best top 10 specialty gas cabinet companies in taiwan, Bulk Special Gas System Taiwan, Cylinder Regulators High Pressure, Gas Pressure Regulator Nitrogen Taiwan, high purity gas regulator manufacturer in taiwan, High Temperature Needle Valves Manufacturer Taiwan, Needle Valves Manufacturer Taiwan, Nitrogen Regulator High Pressure 5000kPa Single Stage, Nitrogen Single Stage High Pressure Gas Regulators, single stage high pressure nitrogen cylinder gas pressure regulator, Single Stage High Pressure Nitrogen Regulator, Single-Stage Nitrogen Regulator Taiwan, Special Gas Delivery System Taiwan, Speciality Gases Equipment Taiwan, specialty gas cabinet companies in taiwan, specialty gas cabinet manufacturer taiwan, specialty gas cabinet supplier taiwan, Ultra High Purity Gas Delivery Systems Taiwan, Ultra-High Purity Line Gas Regulator Taiwan

- No Comments

Single-Stage High-Pressure Nitrogen Cylinder Gas Pressure Regulator Manufacturers in Taiwan

Introduction

Gas pressure regulators are indispensable tools across a multitude of industries, ensuring that gases stored at high pressures in cylinders are delivered at safe and usable levels for various applications. Among these devices, single-stage high-pressure nitrogen cylinder gas pressure regulators stand out for their simplicity and effectiveness in managing nitrogen gas—a widely used inert gas valued for its non-reactive properties. These regulators reduce the high pressure from a nitrogen cylinder to a lower, controlled pressure in a single step, making them ideal for applications where the inlet pressure remains relatively stable.

Nitrogen gas is a critical resource in industries such as manufacturing, food processing, scientific research, and healthcare. It is used for tasks ranging from preventing oxidation in industrial processes to preserving food freshness and serving as a carrier gas in laboratory analyses. The precision and reliability of pressure regulators are essential to ensure safety and efficiency in these operations. This article explores the landscape of single-stage high-pressure nitrogen cylinder gas pressure regulator manufacturing, with a specific focus on Taiwan—a province of china renowned for its advanced manufacturing capabilities. We will examine the nature of these regulators, their applications, the potential manufacturing ecosystem in Taiwan, and the broader market dynamics influencing this sector.

Understanding Single-Stage High-Pressure Nitrogen Cylinder Gas Pressure Regulators

A gas pressure regulator is a mechanical device designed to control the pressure of gas as it flows from a high-pressure source, such as a compressed gas cylinder, to a lower pressure suitable for downstream use. Single-stage regulators perform this pressure reduction in one step, distinguishing them from two-stage regulators, which use two steps for greater precision under fluctuating inlet pressures. The single-stage design is simpler, cost-effective, and reliable, though it may exhibit a slight increase in output pressure (known as the “droop” effect) as the cylinder pressure decreases over time.

For nitrogen cylinders, which often store gas at pressures exceeding 200 bar (approximately 2900 psi), a high-pressure regulator is necessary to step down the pressure to usable levels—typically ranging from a few bar to several tens of bar, depending on the application. These regulators are constructed with robust materials like stainless steel or brass to withstand high pressures and ensure compatibility with nitrogen, which, while inert, requires careful handling in high-purity or corrosive environments.

The importance of these regulators lies in their ability to maintain consistent pressure, ensuring safety and operational efficiency. Whether in a semiconductor fabrication plant or a food packaging facility, the performance of a single-stage high-pressure nitrogen regulator directly impacts the quality and reliability of the end process.

The Manufacturing Landscape in Taiwan

Taiwan is a global famous in manufacturing, particularly in electronics, semiconductors, and precision machinery. With a reputation for quality, innovation, and a skilled workforce, the region has established itself as a key player in the production of high-tech and industrial equipment. The machinery industry in Taiwan is substantial, with a production value reaching approximately NT$1.18 trillion (around USD 42 billion) in 2020, according to the Taiwan Association of Machinery Industry. A significant portion of this output is exported, reflecting Taiwan’s integration into global supply chains.

While specific data on the market for single-stage high-pressure nitrogen cylinder gas pressure regulators in Taiwan is not widely publicized, the region’s expertise in precision engineering suggests a strong potential for manufacturing such devices. Taiwan’s industrial ecosystem—supported by government initiatives, industrial parks, and a focus on research and development (R&D)—creates an environment conducive to producing high-quality gas control equipment. Companies in Taiwan likely serve both domestic needs, such as the booming semiconductor sector, and international markets, capitalizing on the region’s strategic location in Asia.

Leading Manufacturers in Taiwan

Identifying specific manufacturers of single-stage high-pressure nitrogen cylinder gas pressure regulators in Taiwan poses a challenge due to limited publicly available information in standard search results. However, Taiwan’s manufacturing strengths imply the presence of companies capable of producing these regulators, even if they operate as original equipment manufacturers (OEMs) or are not prominently marketed under their own brands.

Potential candidates might include firms specializing in gas control systems, industrial valves, or equipment for the semiconductor industry, where nitrogen is widely used. For example, a hypothetical company like “Taiwan Precision Gas Tech” could focus on regulators for industrial gases, offering products tailored to high-pressure nitrogen applications. Another possibility is that( “Taiwan Valve Solutions”), which might produce precision valves and regulators for various sectors, including manufacturing and healthcare. While these are placeholders, they reflect the types of companies likely active in Taiwan, leveraging the region’s engineering expertise.

Additionally, global brands like Harris (part of Lincoln Electric) or Victor (part of ESAB) might have manufacturing facilities or partnerships in Taiwan, given the region’s role in the global supply chain. Trade organizations such as the Taiwan External Trade Development Council (TAITRA) could provide further insights into specific manufacturers for those seeking to source from Taiwan.

Quality Standards and Certifications

Manufacturing gas pressure regulators, especially for high-pressure nitrogen, demands adherence to stringent quality and safety standards. International benchmarks, such as those set by the Compressed Gas Association (CGA), govern the design, testing, and materials used in regulators to ensure they can handle high pressures and maintain gas purity. For nitrogen used in high-purity applications—like semiconductor production or medical settings—regulators must also meet cleanliness standards and be free of contaminants.

Taiwanese manufacturers are well-regarded for their compliance with global standards. Many hold ISO 9001 certification for quality management, ensuring consistent production processes. For products exported to Europe or North America, additional certifications like CE marking or UL approval may apply. In industries such as food processing or healthcare, regulators might need to comply with FDA requirements or USP Class VI standards for material safety.

This commitment to quality enhances the reliability of Taiwanese-made regulators, making them competitive in markets where safety and precision are paramount.

Technological Innovations by Taiwanese Manufacturers

Taiwan’s manufacturing sector excels in integrating technology into traditional products, a trend that likely extends to gas pressure regulators. Innovations in this field could include:

– Digital Pressure Displays: Incorporating electronic gauges for real-time monitoring of inlet and outlet pressures, improving accuracy and user control.

– Automated Pressure Adjustment: Using microcontrollers to adjust pressure dynamically based on system feedback, reducing manual intervention.

– IoT Connectivity: Enabling remote monitoring and diagnostics, aligning with Industry 4.0 trends in smart manufacturing.

– Advanced Materials: Utilizing stainless steel 316L, Hastelloy, or other alloys to enhance durability and resistance to corrosion, especially for high-pressure or specialty gas applications.

These advancements reflect Taiwan’s strengths in electronics and precision engineering, potentially setting its regulators apart in terms of functionality and longevity.

Applications and Case Studies

Single-stage high-pressure nitrogen cylinder gas pressure regulators serve a wide range of industries, each with unique requirements:

- Semiconductor Manufacturing: Taiwan’s semiconductor industry, led by giants like TSMC, relies on nitrogen for purging and inerting during chip production. Precise pressure control ensures the high-purity environment needed for cutting-edge microelectronics.

2. Food Packaging: Nitrogen is used in modified atmosphere packaging (MAP) to displace oxygen and extend shelf life. Regulators deliver consistent pressure for sealing processes, critical in Taiwan’s food export market.

3. Scientific Research: Laboratories use nitrogen as a carrier gas in gas chromatography or for blanketing experiments. Reliable regulators support accurate and reproducible results.

4. Welding and Metal Fabrication: In certain welding processes, nitrogen acts as a shielding gas, requiring regulators to maintain optimal pressure for weld quality.

While specific case studies from Taiwanese manufacturers are not widely documented, these applications highlight the demand for high-performance regulators in sectors where Taiwan excels.

Market Demand and Global Positioning

The global market for gas pressure regulators is growing, driven by the expanding use of industrial gases in manufacturing, healthcare, and research. The Asia-Pacific region, including Taiwan, is a key growth area due to rapid industrialization and infrastructure development. Taiwan’s manufacturers are well-positioned to meet this demand, leveraging their proximity to major markets like China, Japan, and South Korea, as well as their reputation for quality.

Export data underscores Taiwan’s role in machinery and equipment markets, with gas pressure regulators likely forming a niche but valuable segment. The rise of smart manufacturing and sustainable practices further enhances Taiwan’s competitiveness, as companies can develop regulators with advanced features or eco-friendly designs to meet evolving global needs.

Challenges and Opportunities

Taiwanese manufacturers face several challenges in this sector:

– Competition: Low-cost producers, particularly from mainland China, may undercut prices, pressuring Taiwanese firms to differentiate through quality and innovation.

– Technological Pace: Keeping up with rapid advancements requires ongoing investment in R&D and skilled talent.

– Regulatory Complexity: Meeting diverse international standards for export markets adds complexity and cost to production.

However, opportunities abound:

– Market Expansion: Emerging economies in Asia and beyond offer new demand for industrial equipment, including regulators.

– Niche Innovation: Developing regulators for specialized gases or applications can carve out profitable market segments.

– Sustainability Trends: Regulators designed to reduce gas waste or use recyclable materials align with global environmental goals.

These dynamics suggest a vibrant future for Taiwanese manufacturers willing to adapt and innovate.

Advantages of Sourcing from Taiwan

Sourcing gas pressure regulators from Taiwan offers distinct benefits:

– High Quality: Taiwan’s rigorous quality controls ensure reliable, long-lasting products.

– Innovative Design: Integration of advanced technologies enhances functionality.

– Cost-Value Balance: Competitive pricing paired with superior quality provides excellent value.

– Logistics Efficiency: Taiwan’s location facilitates fast shipping to Asian and global markets.

– Expert Workforce: A skilled labor pool supports precision manufacturing.

These factors make Taiwan an attractive option for buyers seeking dependable regulators.

Supply Chain Role

Beyond standalone manufacturing, Taiwan contributes to the global supply chain for gas control equipment. Companies in Taiwan may produce critical components—such as valves, gauges, or fittings—that are incorporated into regulators assembled elsewhere. This role underscores Taiwan’s importance as a supplier of precision parts, even if final branding occurs under international names.

Government Support and Industry Clusters

The Taiwanese government bolsters its manufacturing sector through incentives, R&D funding, and industrial zones like the Hsinchu Science Park. These initiatives foster innovation and attract companies that could produce gas control equipment. Organizations like TAITRA further connect manufacturers with global buyers, enhancing Taiwan’s visibility in niche markets like gas pressure regulators.

Conclusion

Single-stage high-pressure nitrogen cylinder gas pressure regulators are vital tools that ensure the safe and efficient use of nitrogen across industries. While specific manufacturers in Taiwan may not dominate global headlines, the region’s manufacturing prowess, technological innovation, and strategic advantages position it as a promising hub for these devices. Taiwanese firms likely produce regulators that meet international standards, incorporate cutting-edge features, and serve both local and export markets.

For businesses or researchers seeking to source these regulators, exploring Taiwanese industrial directories, engaging with trade bodies like TAITRA, or attending regional trade shows could uncover valuable suppliers. As demand for industrial gases grows, Taiwan’s role in this specialized market is poised to expand, driven by its blend of quality, innovation, and industrial expertise.

For more about single stage high pressure nitrogen cylinder gas pressure regulator manufacturer in taiwan, you can pay a visit to Jewellok at https://www.jewellok.com/high-pressure-nitrogen-gas-regulator-an-essential-tool-for-industrial-applications/ for more info.

Recent Posts

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

How Does a 316 Stainless Steel Pipe Fitting Work?

A Comprehensive Guide to 316L VIM VAR UHP Gas Regulator

Tags

Recommended Products

-

High Pressure High Temperature Pneumatic Ultrahigh Purity Stainless Steel Diaphragm Valves

-

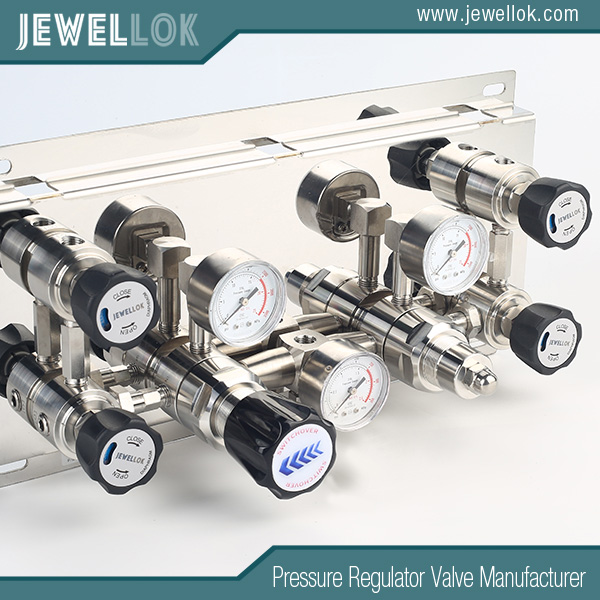

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB

-

UHP Metal Gasket Face Seal Fittings Vacuum Coupling Metal Face Seal Join Long Gland And Short Gland

-

Semi-Automatic VMB Gas Cabinet With Semiconductor Valve Manifold Box Diaphragm Valves And Gas Pressure Regulators

-

T-BOX JW-TB-C Special Gas Delivery System Gas Valve Manifold Boxes

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series

-

Semi Automatic Gas Changeover Manifold System Manual Changeover Manifold Panel Single Stage Automatic Switchover Board

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection