Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Stainless Steel Pressure Reducing Valve Manufacturer in Russia

- Pressure Regulator Valve Manufacturer

- back pressure regulator manufacturers, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, Gas Pressure Reducing Valve, gas regulator valve manufacturers, high pressure ball valve manufacturer, high pressure reducing valve, High Purity L-Type Pressure Reducing Valve, High Purity Pressure Reducing Valve, high purity pressure reducing valves manufacturer, high purity valves manufacturers, high-flow pressure reducing valves, high-flow pressure reducing valves campany, Hydraulic Pressure Reducing Valves, large flow single gauge pressure reducing valve, large-flow pressure reducing valve, large-flow single-gauge pressure reducing valves factory, low pressure valve manufacturer, medical oxygen pressure gauge manufacturer, pressure gauge manufacturers, Pressure Reducing Valve Manufacturer, Semi-automatic Switch Stainless Steel Pressure Reducing Valve, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer, Stainless Steel Pressure Reducing Valve, Stainless Steel Pressure Reducing Valve Manufacturer, Stainless Steel Pressure Reducing Valve Manufacturer in Russia

- No Comments

Stainless Steel Pressure Reducing Valve Manufacturer in Russia

Stainless steel pressure reducing valves (PRVs) are precision-engineered components designed to lower high inlet pressures to a stable, safe outlet pressure, ensuring the protection and efficiency of downstream systems. These valves, crafted from corrosion-resistant stainless steel, are critical in industries such as oil and gas, chemical processing, water treatment, and emerging hydrogen energy systems, where durability and reliability are paramount. Russia, a global leader in energy production and industrial manufacturing, presents a unique market for these specialized valves. This article examines the significance of stainless steel PRVs, the ecosystem of manufacturers and suppliers in Russia, and the technical and logistical considerations for sourcing them. It aims to provide actionable insights for businesses navigating this niche market in Russia, despite the limited availability of specific domestic manufacturers.

The Role and Importance of Stainless Steel Pressure Reducing Valves

Pressure reducing valves function by automatically adjusting high inlet pressures to a predetermined lower outlet pressure, using the energy of the medium itself to maintain stability. From a fluid mechanics perspective, PRVs act as throttling elements, modifying flow to control pressure loss, which prevents over-pressurization that could damage equipment or pose safety risks. Stainless steel, particularly grades like 304, 316, or 904L, is preferred for PRVs due to its corrosion resistance, strength, and compatibility with aggressive media like gases, chemicals, or water in harsh environments.

In Russia, PRVs are vital across diverse applications, from oil and gas pipelines in Siberia to water supply systems in urban centers. The material properties of stainless steel make these valves ideal for handling corrosive gases like hydrogen or chlorine, as well as high-pressure steam or liquids in industrial processes. As Russia invests in clean energy technologies, including hydrogen, the demand for high-performance stainless steel PRVs is expected to grow, underscoring the need for reliable manufacturers and suppliers.

Russia’s Industrial and Manufacturing Landscape

Russia is a global powerhouse in energy and industrial production, with a significant presence in oil and gas, mining, chemical processing, and power generation. The country’s vast natural gas reserves and leadership in pipeline infrastructure drive demand for robust industrial components like PRVs. Additionally, Russia’s push toward energy diversification, including hydrogen projects under its 2020 Hydrogen Development Strategy, signals growing opportunities for specialized valve manufacturing. The country’s industrial sector is supported by a strong engineering tradition and government policies promoting domestic production, such as import substitution initiatives.

However, Russia’s valve manufacturing industry faces challenges, including sanctions and limited access to advanced technologies, which may impact the production of niche components like stainless steel PRVs. While companies like Jayant Engineering & Marketing Pvt. and Citizen Metals export a range of industrial valves to Russia, specific data on domestic manufacturers of stainless steel PRVs is scarce, suggesting a reliance on imports or a developing local market for these specialized products.

The Need for Reliable Manufacturers and Suppliers in Russia

The demand for stainless steel pressure reducing valves in Russia highlights the need for reliable manufacturers and suppliers capable of delivering high-quality, standards-compliant products. These valves must meet stringent international standards, such as the European Pressure Equipment Directive (PED) 2014/68/EU, API 6D, or Russian GOST standards, to ensure safety and performance in demanding applications. Key requirements include corrosion resistance, leak-tightness, and durability under high pressures (up to 400 bar in some cases) and temperatures (up to 190°C for steam applications).

While Russia has a robust valve industry, with companies like those under the “Russian Gate” brand producing pipeline components, the production of stainless steel PRVs appears limited. International suppliers like NieRuf (Germany) and Suraj Metal Corporation (India) offer stainless steel PRVs for the Russian market, with products like 316 stainless steel valves for water and gas applications. Local manufacturers may focus on broader valve categories, such as gate or check valves, leaving a gap for specialized PRVs that domestic companies could fill as demand grows.

Leveraging Global and Local Marketplaces for Sourcing

Given the limited domestic production of stainless steel PRVs, Russian businesses often turn to global B2B platforms to source these components. Platforms like Hyfindr provide access to PRVs designed for high-pressure and high-purity applications, such as hydrogen systems, with detailed specifications and certifications. NieRuf’s online shop, for example, offers stainless steel PRVs with FPM/FKM or EPDM seals for liquid and gaseous media, suitable for pressures from 0.5 to 15 bar. Similarly, Valves Online and Syveco list stainless steel PRVs with BSP or NPT connections, catering to air, water, and steam applications.

Locally, Russia’s industrial ecosystem is supported by organizations like the Russian Valve Industry Association and trade shows such as PCVExpo in Moscow, which connect buyers with manufacturers and suppliers. These events showcase a range of valves, including those from companies like Kalp Industries, which exports stainless steel instrumentation valves to Russia, including 304, 316, and 904L grades for high-pressure applications. As Russia’s hydrogen and industrial sectors grow, these platforms could facilitate the entry of local manufacturers into the PRV market.

Technical Considerations for Selecting Stainless Steel Pressure Reducing Valves

Selecting the appropriate stainless steel PRV requires careful evaluation of technical specifications to ensure compatibility, safety, and performance. Key considerations include:

- Material Compatibility: Stainless steel grades like 304 or 316 are ideal for corrosive environments, with 316 offering superior resistance to chlorides and marine conditions. For example, Suraj Metal’s 316 PRVs are designed for hydraulic and gas applications.

- Pressure Range: PRVs must handle high inlet pressures (e.g., 20–400 bar) and deliver stable outlet pressures (e.g., 0.5–15 bar), as seen in NieRuf’s precision PRVs.

- Flow Capacity: The flow coefficient (Cv) determines the valve’s ability to handle required flow rates, critical for applications like gas distribution or water systems.

- Certifications: Compliance with PED, API, or DVGW (for drinking water) ensures safety and regulatory adherence, as offered by suppliers like Valves Online.

- Leak Tightness: High-quality seals (e.g., NBR, FPM/FKM, or EPDM) prevent leaks, essential for gases like hydrogen or corrosive liquids.

- Temperature Range: Valves must operate within system temperatures, typically -15°C to 190°C for stainless steel PRVs, as noted by NieRuf.

Manufacturers should offer customization options, such as adjustable pressure settings or specific connection types (e.g., BSPT, NPT), to meet project needs.

Types of Stainless Steel PRVs

Different types of PRVs suit various applications:

- Direct-Acting PRVs: Compact and simple, ideal for low to medium flow rates, like TLV’s stainless steel PRVs for clean steam.

- Pilot-Operated PRVs: Provide precise control for high-pressure or fluctuating conditions, suitable for oil and gas pipelines.

- High-Pressure PRVs: Designed for extreme pressures (up to 400 bar), as offered by Syveco for NPT connections.

- Automatic PRVs: Used in industrial systems for hands-free pressure control, like Suraj Metal’s high-flow PRVs.

Understanding these types helps businesses select valves tailored to their applications.

Case Study: Sourcing PRVs for a Hydrogen Pipeline Project

Consider a hypothetical scenario where a Russian energy company is developing a hydrogen pipeline in the Ural region to supply fuel cell vehicles. The project requires stainless steel PRVs to reduce hydrogen pressure from 350 bar to 10 bar for safe dispensing. The company explores global suppliers through Hyfindr and identifies a 316 stainless steel PRV from NieRuf, with FPM seals and PED certification, suitable for high-pressure gas applications. A regional distributor in Moscow offers technical support and delivery within a week, ensuring compliance with GOST standards. This solution allows the company to meet safety and performance requirements, highlighting the role of global supply chains in Russia’s hydrogen sector.

Future Outlook for Selecting Stainless Steel Pressure Reducing Valves in Russia

Russia’s industrial and energy ambitions signal a promising future for stainless steel PRVs. The country’s hydrogen strategy and investments in oil and gas, water treatment, and chemical processing will drive demand for these components. As sanctions ease or domestic capabilities grow, local manufacturers could expand into niche markets like stainless steel PRVs, reducing reliance on imports from companies like Suraj Metal or Kalp Industries.

Advancements in valve design, such as low-leakage technologies or smart PRVs with integrated sensors, could align with Russia’s push for Industry 4.0. Trade agreements with Asia and Europe may also enhance Russia’s role as an exporter of industrial components, with companies like those under the Russian Gate brand potentially leading the way.

Conclusion

The market for stainless steel pressure reducing valves in Russia is developing, driven by the country’s industrial and energy sectors. While domestic manufacturing of these specialized valves is limited, global suppliers like NieRuf, Suraj Metal, and Kalp Industries provide high-quality options, supported by platforms like Hyfindr and local trade shows. By prioritizing technical specifications, certifications, and reliable support, Russian businesses can secure the right PRVs for their needs. As demand grows, fostering local manufacturing capabilities will be key to strengthening Russia’s role in the global valve market, supporting its industrial and clean energy ambitions.

For more about the stainless steel pressure reducing valve manufacturer in russia, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

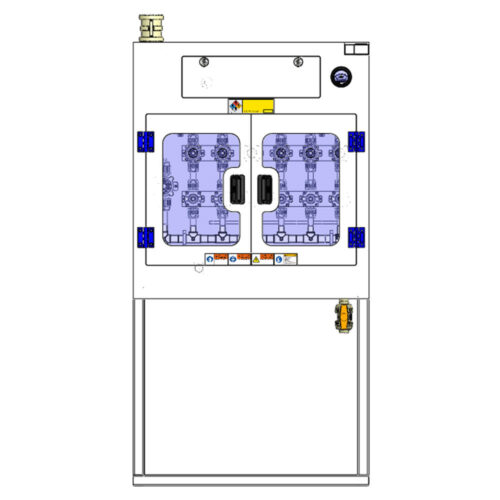

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases

-

772L Male Branch Tee | Stainless Steel High-Purity Tube Fitting Male Branch Tee

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

Semi-Automatic VMB Gas Cabinet With Semiconductor Valve Manifold Box Diaphragm Valves And Gas Pressure Regulators

-

UHP Metal Gasket Face Seal Fittings Vacuum Coupling Metal Face Seal Join Long Gland And Short Gland

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases