Blog

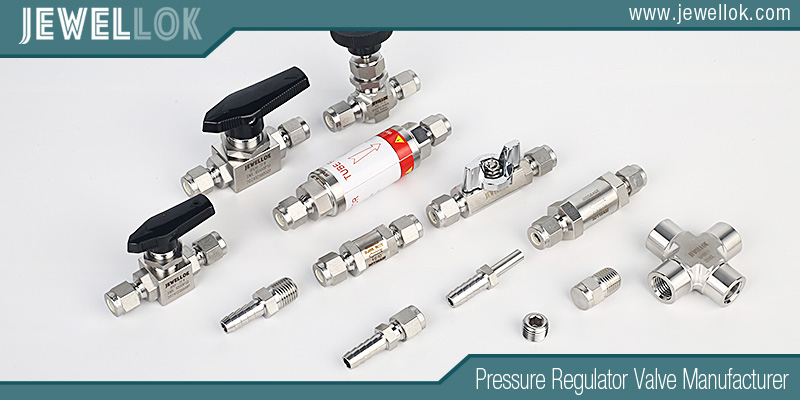

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

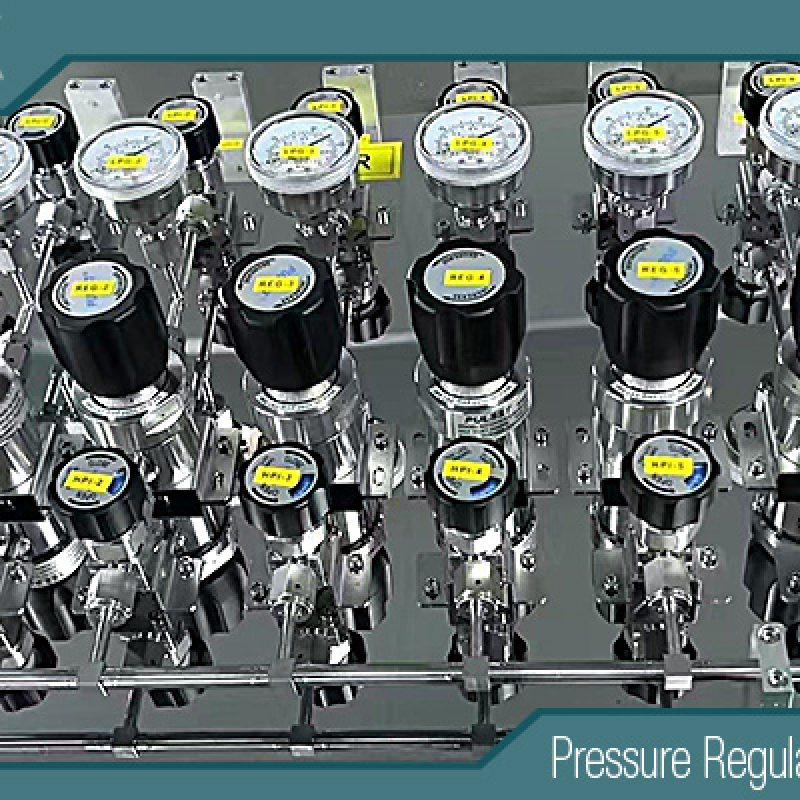

The Adjustable Back Pressure Regulator Application Guide

- Pressure Regulator Valve Manufacturer

- 1/2 Gas Pressure Regulator manufacturer, 2 stage nitrogen regulator, 316L Stainless Steel Gas Pressure Regulators, adjustable air pressure regulator, adjustable back pressure regulator, Adjustable Back Pressure Regulator Factory, Adjustable Back Pressure Regulator Manufacturer, Adjustable Back Pressure Regulator Supplier, adjustable high pressure regulator, adjustable hydraulic pressure regulator, Adjustable Pressure Regulators, adjustable propane pressure regulator, air compressor pressure regulator, air pressure regulator, back pressure reducing valve, Back Pressure Reducing Valve Manufacturer, Back Pressure Regulator, china high pressure air regulator valve manufacturer, Double Block and Bleed valve manufacturers, gas regulator valve manufacturers, high flow needle valve manufacturer, high pressure ball valve manufacturer, high pressure hydraulic needle valve manufacturer, high pressure needle valve manufacturer, industrial diaphragm valve manufacturers, low pressure back pressure regulator, low pressure valve manufacturer, medical oxygen pressure gauge manufacturer, needle valve 10000 psi manufacturer, pneumatic actuated ball valve manufacturer, pressure control valve manufacturers, Pressure Reducing Valve, pressure relief valve manufacturers, sanitary back pressure regulator, single stage propane regulator

- No Comments

The Adjustable Back Pressure Regulator Application Guide

In the realm of fluid control systems, the adjustable back pressure regulator stands as a critical component for maintaining system stability and efficiency. This device is designed to control and sustain a consistent upstream pressure in pipelines, vessels, and processing equipment, regardless of fluctuations in flow rates or downstream conditions. By allowing excess pressure to be relieved while preventing backflow or pressure drops, it ensures safe and optimal operation across various industries.

The concept of back pressure regulation dates back to early industrial applications where maintaining precise pressure was essential for process integrity. Today, adjustable back pressure regulators are indispensable in sectors like oil and gas, chemical processing, pharmaceuticals, and even analytical sampling systems. Their adjustability allows operators to fine-tune setpoints to match specific operational needs, making them versatile tools for engineers and technicians.

Understanding the adjustable back pressure regulator involves exploring its mechanics, types, and practical uses. This article delves into the working principles, various designs, applications, advantages, disadvantages, selection criteria, installation guidelines, and maintenance practices. Drawing from technical insights, it aims to provide a comprehensive overview for professionals seeking to implement or optimize these regulators in their systems. Whether you’re dealing with high-flow gas systems or sensitive liquid processes, grasping these elements can enhance system performance and longevity.

At its core, an adjustable back pressure regulator functions by balancing forces to maintain inlet pressure. When upstream pressure exceeds the setpoint, the valve opens to release fluid, and closes when pressure normalizes. This dynamic adjustment prevents overpressurization and ensures steady flow, protecting downstream equipment from damage. The ability to adjust the setpoint via springs, screws, or pilots distinguishes it from fixed regulators, offering flexibility in variable environments.

In modern engineering, these regulators address challenges like pressure spikes in compressor stations or consistent flow in sampling lines. Their evolution from simple mechanical devices to sophisticated pilot-operated models reflects advancements in materials and control technology, enabling precise control even in harsh conditions.

What is an Adjustable Back Pressure Regulator?

An adjustable back pressure regulator, often abbreviated as BPR, is a specialized valve that maintains a predefined pressure level upstream of its installation point. Unlike pressure-reducing regulators that control downstream pressure, BPRs focus on inlet pressure, opening to relieve excess when it surpasses the setpoint and closing to build pressure when it falls below. This makes them essential for systems where upstream stability is paramount.

The “adjustable” aspect refers to the ability to modify the setpoint pressure, typically through a mechanical screw, knob, or external pilot system. This feature allows for on-the-fly adjustments without system shutdown, catering to dynamic operational demands. Constructed from durable materials like stainless steel or alloys, these regulators handle gases, liquids, mixed-phase fluids, and even supercritical substances. Key components include a sensing element (diaphragm or piston), a loading mechanism (spring or dome pressure), and a valve seat. The sensing element detects pressure changes, while the loading mechanism sets the balance point. In dome-loaded designs, fluid pressure in the dome chamber provides the reference, offering superior precision over spring-loaded variants. BPRs differ from relief valves, which are safety devices for sudden pressure surges, by providing continuous, steady-state control rather than intermittent release. They are also known as pressure-sustaining valves, especially in pump recirculation setups where excess flow is looped back to maintain pressure. In practical terms, an adjustable BPR ensures that production vessels like separators or treaters operate at optimal pressure, facilitating efficient fluid separation and processing. Their compact size and self-operating nature make them suitable for both small-scale lab environments and large industrial plants.

Working Principle

The working principle of an adjustable back pressure regulator revolves around force balance to achieve precise pressure control. At its simplest, the regulator uses a sensing mechanism to compare upstream pressure against a setpoint force, adjusting the valve position accordingly. In a typical setup, fluid enters the regulator’s inlet, exerting pressure on the sensing element—often a diaphragm or piston. This element is opposed by a loading force, such as a compressed spring or reference pressure in the dome. When upstream pressure exceeds the setpoint, the sensing element moves, opening the valve to allow flow through the orifice and relieve pressure. As pressure drops to the setpoint, the loading force closes the valve, maintaining equilibrium. For adjustability, the setpoint is modified by altering the loading force. In spring-loaded models, turning an adjustment screw compresses or relaxes the spring, changing the force balance. Dome-loaded regulators use an external pilot to supply reference pressure to the dome, enabling remote or automated adjustments via electronic controls. Pilot-operated designs enhance this principle with a two-stage system: a small pilot valve senses pressure and modulates the main valve’s position for faster response and minimal deviation across flow variations. This is particularly useful in high-flow scenarios where direct-acting regulators might exhibit “pressure buildup” or droop.

In applications like sampling systems, the BPR is placed at the line’s end, diverting excess flow to a bypass while maintaining constant analyzer pressure. An upstream flow restrictor ensures effective pressure drop, preventing the regulator from staying wide open. Overall, the principle ensures steady-state operation, with the regulator continuously modulating to adapt to changes, reducing turbulence and enhancing system durability.

Types of Adjustable Back Pressure Regulators

Adjustable back pressure regulators come in several types, each tailored to specific operational needs based on precision, flow capacity, and environmental factors.

- Self-Contained or Direct-Acting Regulators: These are the most basic, relying on internal springs and diaphragms without external power. Adjustment is via a screw compressing the spring. They suit stable flows but may show pressure buildup at higher rates due to proportional control. Advantages include simplicity and cost-effectiveness; ideal for general-purpose applications.

- Differential or Tracking Regulators: These maintain a fixed pressure difference between two system points using a reference pressure input. Adjustment involves biasing the setpoint against the reference. They prevent backflow in systems like compressor seals, offering high precision in differential control.

- Pilot-Operated Regulators: Featuring a pilot valve controlling the main valve, these provide tight control across wide flow ranges. Setpoint adjustment is through the pilot, often remotely. They excel in dynamic environments like chemical processes, with minimal deviation.

- Dome-Loaded Regulators: Using fluid pressure in a dome for loading, these offer superior stability and low hysteresis. Adjustment via a pilot regulator allows for electronic integration. Sizes range from small research series (1/16″ to 1/4″) to industrial (up to 4″), handling pressures up to 10,000 psig.

- Spring-Loaded Regulators: A subset where springs provide the load, adjustable manually. They are compact but less precise with varying flows due to spring constant changes.

- Electronic Series: Combining dome-loading with electronic pilots for automated control, suitable for pressures up to 5000 psig.

Each type’s selection depends on factors like flow rate, precision needs, and material compatibility, with stainless steel often used for corrosive environments.

Applications

Adjustable back pressure regulators find widespread use across industries where pressure stability is crucial.

In oil and gas, they maintain pressure in separators, treaters, and free water knockouts, ensuring efficient fluid separation and preventing equipment damage. Compressor stations and gas gathering systems rely on them for safety and flow control.

Chemical processing benefits from their precision in handling reactive fluids, reducing turbulence and overpressure risks. Pharmaceuticals use them in sterile environments for consistent dosing and mixing.

In analytical sampling systems, BPRs ensure steady flow to analyzers by bypassing excess, protecting sensitive instruments from pressure variations. Pump systems employ them as sustaining valves, recirculating excess flow to maintain upstream pressure. Food and beverage industries apply them for hygienic pressure control in processing lines.

Power generation and water treatment utilize pilot-operated types for high-flow precision. Overall, their adaptability makes them vital for safety, efficiency, and compliance.

Advantages and Disadvantages

Advantages of adjustable back pressure regulators include precise pressure control, reducing system damage and enhancing safety. They minimize turbulence, extend equipment life, and offer flexibility through adjustability. Dome-loaded models provide high stability across flows, while self-operated ones are economical and easy to install. Disadvantages involve potential hysteresis in spring-loaded types, leading to overpressure. Pilot-operated designs are more complex and costly. Maintenance demands can increase downtime if neglected, and improper sizing may cause inefficiencies.

Selection Criteria

Selecting an adjustable BPR requires evaluating application needs: flow rate, pressure range, fluid type, and precision. Consider material durability for corrosive environments and modular designs for maintenance ease. Prioritize suppliers with strong support and quality reputations. For high precision, opt for dome or pilot-operated; for simplicity, self-contained.

Installation Guidelines

Proper installation starts with placing the BPR at the line’s end for upstream control. Include an upstream flow restrictor to enable pressure drop. Remove any shipping stoppers before operation. For series setups, add restrictors between regulators to avoid competition. Ensure dry gas supply and adjust setpoints gradually. Use OEM guidelines for connections and seals.

Maintenance Tips

Maintenance involves daily leak checks, monthly visuals, quarterly inspections, and annual replacements of diaphragms and seals. Clean with approved solvents, lubricate properly, and use rebuild kits for minor issues. Troubleshoot venting by checking diaphragms or seats; replace for severe damage. Document activities for compliance.

Conclusion

Adjustable back pressure regulators are pivotal for pressure management, offering reliability and adaptability. By understanding their principles and practices, engineers can optimize systems for peak performance.

For more about the adjustable back pressure regulator application guide, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

BSGS Large Flow Specialty Gas Supply Cabinet 3 Cylinder Gas Storage Cabinet Fully Automated PLC Control Bulk Specialty Gas Systems (BSGS) Gas Cabinets

-

Stainless Steel Fully Automatic Gas Switchover Manifold System Automatic Gas Cylinder Switchover Co2 Cylinder Auto Changeover Controller

-

Semi Automatic Gas Changeover Manifold System Manual Changeover Manifold Panel Single Stage Automatic Switchover Board

-

768LN Stainless Steel Male Pipe Tube Butt Weld Connector And Tube Fittings Supplier

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

Stainless Steel Ultra High Purity Mini Butt Weld Mini Tee Reducer MTRW Series Fittings

-

Semi-Automatic VMB Gas Cabinet With Semiconductor Valve Manifold Box Diaphragm Valves And Gas Pressure Regulators

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series