Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

The Design and Applications of Oxygen Changeover Manifold

- Pressure Regulator Valve Manufacturer

- 1 2 propane regulator, 1/2 gas pressure regulator, 316l stainless steel pressure regulator, adjustable air pressure regulator, adjustable hydraulic pressure regulator, adjustable propane pressure regulator, Air Compressor Check Valve, air pressure regulator electronic control, Air Pressure Regulator Manufacturer, argon hose connector, automatic switching valve, Back Pressure Regulating Valve, Brass Pressure Regulator, Changeover Manifold, China Stainless Steel Pressure Regulator, gas pipeline valve, gas regulator, Gas Solenoid Valve, high flow co2 regulator, high grade stainless steel pressure regulator, low pressure gas regulator, Medical Oxygen Regulator, Oxygen changeover manifold, oxygen changeover manifold manufacturer, oxygen changeover manifold market, oxygen changeover manifold supplier, oxygen changeover manifold systems, pressure regulator, pressure safety valve vs relief valve, propane pressure regulator valve, safety valve and relief valve, Stainless Steel Ball Valve, Stainless Steel Diaphragm Valve, Stainless Steel Needle Valve, Stainless Steel Pressure Regulator, stainless steel pressure regulators manufacturer, Stainless Steel Tube Fittings

- No Comments

The Design and Applications of Oxygen Changeover Manifold

Oxygen changeover manifolds are critical components in systems requiring a continuous and reliable supply of oxygen, such as in medical facilities, industrial processes, and research laboratories. These sophisticated devices ensure an uninterrupted flow of oxygen by automatically switching between multiple gas sources, such as cylinders or bulk tanks, when one source is depleted. As oxygen is a vital resource in numerous applications, from life-saving medical treatments to industrial manufacturing, the reliability and efficiency of changeover manifolds are paramount. This article delves into the design, functionality, applications, benefits, challenges, and future prospects of oxygen changeover manifolds, highlighting their essential role in modern systems.

What is an Oxygen Changeover Manifold?

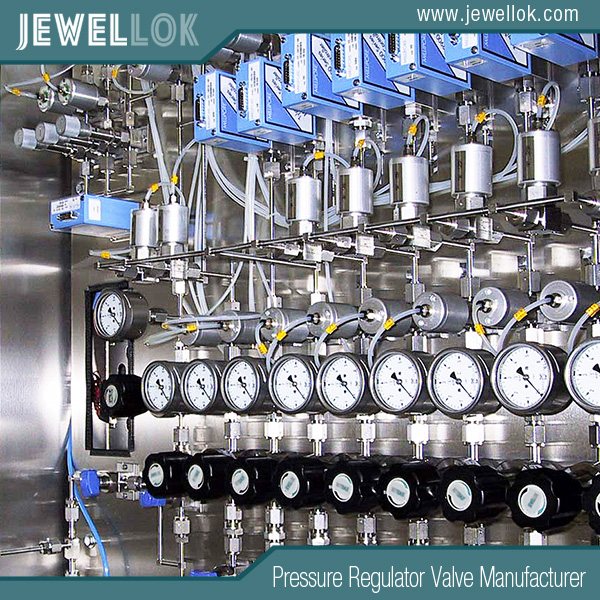

An oxygen changeover manifold is a specialized system designed to manage the supply of oxygen from multiple sources, ensuring a continuous and stable flow to downstream applications. The manifold typically connects two or more oxygen sources—such as high-pressure cylinders, liquid oxygen tanks, or oxygen concentrators—and automatically switches between them when the primary source reaches a predetermined low-pressure threshold. This seamless transition prevents interruptions in oxygen delivery, which is critical in environments where even brief disruptions can have serious consequences.The core components of an oxygen changeover manifold include:

- Inlet Connections: These connect the manifold to the oxygen sources, typically equipped with regulators to control pressure.

- Pressure Regulators: These maintain a consistent output pressure, regardless of the input pressure from the gas source.

- Changeover Valve or Mechanism: This is the heart of the manifold, responsible for switching between primary and reserve oxygen sources. It can be mechanical, pneumatic, or electronically controlled.

- Pressure Sensors and Gauges: These monitor the pressure levels in each source to trigger the changeover when necessary.

- Outlet Connection: This delivers the regulated oxygen flow to the downstream system, such as a hospital’s piped gas network or an industrial process line.

- Control System: In advanced manifolds, an electronic control unit or programmable logic controller (PLC) manages the changeover process, monitors system status, and provides alerts for maintenance or low-pressure conditions.

Changeover manifolds can be manual, semi-automatic, or fully automatic, depending on the application. Manual manifolds require an operator to switch sources, while automatic systems use pressure sensors and actuators to perform the changeover without human intervention. Fully automatic manifolds are the most common in critical applications due to their reliability and minimal need for oversight.

Design Considerations for Oxygen Changeover Manifolds

Designing an oxygen changeover manifold requires careful consideration of several factors to ensure safety, reliability, and compatibility with the intended application. Oxygen is a highly reactive gas, and improper handling can lead to fire hazards or equipment failure.

Key design considerations include:

- Material Compatibility

Oxygen manifolds must be constructed from materials that are resistant to corrosion and compatible with high-purity oxygen. Common materials include stainless steel, brass, and specialized alloys. Components must be free of contaminants, such as oils or grease, which can ignite in the presence of oxygen under high pressure.

- Pressure Regulation

Oxygen is typically stored at high pressures (up to 2000-3000 psi in cylinders), but most applications require lower, stable pressures (e.g., 50-100 psi for medical systems). The manifold’s regulators must reduce and stabilize pressure without introducing fluctuations that could disrupt downstream processes.

- Safety Features

Safety is paramount in oxygen manifold design. Features such as pressure relief valves, check valves to prevent backflow, and fail-safe mechanisms ensure safe operation. Additionally, manifolds may include alarms or digital displays to alert operators to low pressure, leaks, or system malfunctions.

- Scalability and Modularity

Manifolds are often designed to be scalable, allowing additional cylinders or tanks to be added as demand increases. Modular designs facilitate maintenance and upgrades, enabling components to be replaced without shutting down the entire system.

- Compliance with Standards

Oxygen manifolds must comply with strict regulatory standards, such as those set by the National Fire Protection Association (NFPA), International Organization for Standardization (ISO), or local health and safety authorities. In medical applications, compliance with standards like NFPA 99 (Health Care Facilities Code) or ISO 7396-1 (Medical Gas Pipeline Systems) is critical.

- Automation and Monitoring

Modern manifolds often incorporate advanced automation and monitoring systems. These may include remote monitoring capabilities, integration with building management systems (BMS), and real-time data logging to track gas usage and system performance.

Applications of Oxygen Changeover Manifolds

Oxygen changeover manifolds are used in a wide range of industries and settings where a reliable oxygen supply is essential.

Below are the primary applications:

- Medical and Healthcare Facilities

In hospitals, clinics, and emergency care centers, oxygen changeover manifolds are integral to medical gas pipeline systems. They ensure a continuous supply of medical-grade oxygen to operating rooms, intensive care units, and patient wards. The automatic changeover feature is critical in these settings, as any interruption in oxygen delivery could jeopardize patient safety. Manifolds in medical applications are often paired with backup systems and alarms to comply with stringent regulations.

- Industrial Processes

Oxygen is widely used in industrial applications, such as metal cutting, welding, and chemical manufacturing. In these processes, changeover manifolds maintain a steady oxygen supply to equipment like plasma cutters, oxy-fuel torches, or reactors. The ability to switch between cylinders or bulk tanks ensures uninterrupted production, minimizing downtime and maintaining efficiency.

- Research Laboratories

Laboratories conducting experiments in chemistry, biology, or materials science often require precise and reliable oxygen supplies. Changeover manifolds provide the necessary control and continuity, supporting applications such as gas chromatography, environmental testing, or combustion studies.

- Aerospace and Defense

In aerospace facilities, oxygen manifolds supply oxygen for testing rocket engines, life support systems, or high-altitude simulations. The precision and reliability of these manifolds are critical to ensuring the safety and success of such high-stakes applications.

- Aquaculture and Water Treatment

Oxygen is used in aquaculture to maintain water quality for fish and other aquatic organisms. Changeover manifolds ensure a consistent oxygen supply to aeration systems, supporting healthy aquatic environments. Similarly, in water treatment plants, oxygen is used in processes like ozonation, where manifolds maintain steady gas flow.

Benefits of Oxygen Changeover Manifolds

The adoption of oxygen changeover manifolds offers numerous advantages, making them indispensable in critical applications.

Key benefits include:

- Uninterrupted Oxygen Supply

The primary function of a changeover manifold is to ensure a continuous oxygen supply, even when one source is depleted. This is particularly vital in medical and industrial settings where interruptions can have severe consequences.

- Improved Safety

Automatic changeover manifolds reduce the need for manual intervention, minimizing the risk of human error. Built-in safety features, such as pressure relief valves and alarms, further enhance system safety.

- Operational Efficiency

By automating the switch between gas sources, manifolds reduce downtime and labor costs associated with manual cylinder changes. This is especially beneficial in high-demand environments like hospitals or manufacturing plants.

- Cost Savings

While the initial investment in a changeover manifold may be significant, the long-term savings are substantial. Reduced downtime, lower labor costs, and optimized gas usage contribute to overall cost efficiency.

- Flexibility and Scalability

Changeover manifolds can be tailored to specific applications, with options for manual, semi-automatic, or fully automatic operation. Their modular design allows for easy expansion as demand grows.

- Compliance with Regulations

Manifolds designed for medical or industrial use are built to meet strict regulatory standards, ensuring compliance and reducing the risk of penalties or operational shutdowns.

Challenges and Limitations

Despite their advantages, oxygen changeover manifolds face several challenges that must be addressed to ensure optimal performance and widespread adoption.

- High Initial Costs

The cost of designing, manufacturing, and installing a high-quality oxygen changeover manifold can be significant, particularly for fully automatic systems with advanced monitoring capabilities. This may deter smaller facilities or businesses with limited budgets.

- Maintenance Requirements

Manifolds require regular maintenance to ensure reliable operation. Components such as regulators, valves, and sensors must be inspected and serviced periodically to prevent leaks, pressure fluctuations, or system failures.

- Complexity of Installation

Installing a changeover manifold, especially in existing facilities, can be complex and time-consuming. Retrofitting older buildings may require upgrades to piping, electrical systems, or control infrastructure, adding to project costs.

- Risk of Contamination

Oxygen manifolds must be kept free of contaminants to prevent combustion risks or degradation of gas purity. This requires rigorous cleaning and maintenance protocols, particularly in medical and laboratory settings.

- Dependence on Power Supply

Fully automatic manifolds rely on electrical power for sensors, actuators, and control systems. Power outages or failures could disrupt operation unless backup power systems are in place.

Future Prospects of Oxygen Changeover Manifolds

As technology advances and demand for reliable oxygen systems grows, oxygen changeover manifolds are poised for significant developments.

Key trends shaping their future include:

- Smart and IoT Integration

The integration of Internet of Things (IoT) technology is transforming oxygen manifolds into smart systems. Real-time monitoring, predictive maintenance, and remote control capabilities are becoming standard features, allowing operators to optimize performance and reduce downtime.

- Energy Efficiency

Advancements in low-power electronics and energy-efficient components are reducing the power consumption of automatic manifolds, making them more sustainable and cost-effective.

- Compact and Modular Designs

Manufacturers are developing more compact and modular manifolds to accommodate space-constrained environments, such as small clinics or mobile medical units. These designs also simplify installation and maintenance.

- Enhanced Safety Features

Ongoing research is focused on improving safety through advanced materials, fail-safe mechanisms, and real-time diagnostics. For example, next-generation manifolds may include AI-driven algorithms to detect and mitigate potential issues before they escalate.

- Sustainability and Green Manufacturing

As industries prioritize sustainability, manufacturers are exploring eco-friendly materials and production processes for manifolds. Additionally, systems that optimize oxygen usage can reduce waste and support green initiatives.

Conclusion

Oxygen changeover manifolds are indispensable tools in ensuring a reliable and continuous supply of oxygen across a range of critical applications. From medical facilities to industrial plants and research laboratories, these systems provide safety, efficiency, and flexibility in managing oxygen resources. While challenges such as high costs and maintenance requirements exist, advancements in automation, IoT integration, and material science are driving the evolution of this technology. As industries continue to prioritize reliability, safety, and sustainability, oxygen changeover manifolds will play an increasingly vital role in supporting modern infrastructure. By blending robust engineering with cutting-edge innovation, these systems are poised to meet the growing demands of a rapidly changing world.

For more about the design and applications of oxygen changeover manifold, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

Ultra High Purity Stainless Steel Compressed Gas Changeover Manifold Panel System For Integrated Gas Supply System

-

767LT Reducer Pressure Reducing Valve Adjustment High purity Pressure Reducing Union Fittings And Tubing

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve

-

Stainless Steel Ultra High Purity Mini Butt Weld Mini Tee Reducer MTRW Series Fittings