Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Top-Quality Single Stage High Pressure Gas Regulators Supplier in Vietnam

- Pressure Regulator Valve Manufacturer

- 1 1 2 gas pressure regulator, 1 2 gas regulator, 1 2 propane regulator, 1/2 gas pressure regulator, 12v electric valve, 2 electric valve, 2 inch irrigation solenoid valve, 6mm compression union, Adjustable Helium Single Stage High Pressure Gas Regulator, adjustable propane pressure regulator, argon gas pressure regulator, Diaphragm Valve Manufacturers, electric water valve, gas cylinder, gas regulator, gas used in semiconductor chip manufacturing, high pressure argon regulator, high purity regulator, industrial regulators, lab fittings exporter, oxygen regulator gauge, pressure regulator, pressure safety valve vs relief valve, propane pressure regulator valve, relief valve and safety valve difference, safety valve vs relief valve, semiconductor gas, Single Stage High Pressure Gas Regulator, single stage high pressure gas regulators, single stage high pressure gas regulators in china, single stage high pressure gas regulators manufacturer in turkey, Single Stage High Pressure Gas Regulators Supplier, valve manifold box, what is a flame arrestor

- No Comments

Single-stage high-pressure gas regulators are critical devices for controlling the flow and pressure of gases from high-pressure cylinders, ensuring safe and efficient operations across various industries. These regulators reduce high inlet pressures to usable levels in a single step, making them ideal for applications where precise pressure stability is not critical or where operators can monitor and adjust settings. In Vietnam, a rapidly developing industrial hub in Southeast Asia, the demand for high-quality gas regulators is growing, driven by sectors like manufacturing, electronics, oil and gas, and medical applications. This article explores the function of single-stage high-pressure gas regulators, their key features, their role in Vietnam’s industries, and the leading suppliers in the country, providing guidance for businesses seeking reliable solutions.

Understanding Single-Stage High-Pressure Gas Regulators

Single-stage high-pressure gas regulators are devices designed to reduce the high pressure of gases stored in cylinders—often exceeding 200 bar (2,900 psi)—to a safe, usable level for specific applications. Unlike dual-stage regulators, which reduce pressure in two steps for greater precision, single-stage regulators perform this reduction in one step, making them simpler and more cost-effective. However, they may exhibit slight increases in outlet pressure as cylinder pressure decreases, requiring occasional manual adjustments.

These regulators are typically constructed with a piston or diaphragm mechanism. Piston-type regulators are suited for high-pressure applications due to their durability, while diaphragm-type regulators are preferred for high-purity or mildly corrosive gases to prevent contamination. They are used with a variety of gases, including nitrogen, oxygen, argon, hydrogen, and corrosive gases like ammonia, depending on the regulator’s material and design.

Single-stage regulators are widely used in industries where simplicity and cost-efficiency are prioritized. In welding, they control shielding gases like argon or nitrogen for consistent welds. In HVAC and refrigeration, they facilitate pressure testing and purging. In laboratories, they support experiments requiring moderate pressure control, while in oil and gas, they manage high-pressure gases for processing and testing. Their versatility makes them a staple in industrial and scientific settings.

Key Features of High-Quality Single-Stage Regulators

High-quality single-stage high-pressure gas regulators are defined by features that ensure reliability, safety, and performance. Material compatibility is paramount, as regulators must withstand high pressures and resist corrosion. Brass regulators, often chrome-plated, are common for non-corrosive gases like nitrogen or oxygen, while stainless steel (e.g., SS 316) is preferred for corrosive gases like ammonia or chlorine to ensure durability and prevent contamination.

Pressure control is a critical feature. Single-stage regulators can handle inlet pressures up to 300 bar (4,350 psi) and reduce them to working ranges like 0-100 psig or 0-500 psi, depending on the application. For example, the HPR-369 series from Super Safety Services offers outlet pressures from 0-100 psig to 0-1300 psig, with an internal surface finish of 1.6 µm for easier cleaning and reduced particle contamination.

Safety features are essential for high-pressure applications. Regulators typically include dual pressure gauges compliant with ISO 5171 to monitor cylinder and outlet pressures, safety relief valves to prevent over-pressurization, and sintered bronze inlet filters to protect internal components from debris. Some models, like the GCE Unicontrol, feature non-detachable control knobs and integrated pressure relief valves at the rear to prevent tampering, enhancing safety in aggressive environments.

High-pressure capability and ease of use are also key. Regulators like the Harris Model 3500 are designed for high-pressure, high-flow manifold systems, offering robust performance for industrial applications. Features like color-coded control elements and ergonomic knobs, as seen in GCE regulators, improve usability and safety.

The Role of Gas Regulators in Vietnam’s Industries

Vietnam’s industrial landscape is experiencing rapid growth, driven by foreign investment, a skilled workforce, and government initiatives like the Industrial Strategy 2025. Key sectors such as electronics, manufacturing, oil and gas, and medical applications rely heavily on single-stage high-pressure gas regulators to ensure operational efficiency and safety.In electronics, Vietnam is a major hub for semiconductor and consumer electronics manufacturing, with companies like Samsung and LG operating large facilities. Single-stage regulators are used to control high-purity gases like nitrogen for cleanroom environments and chip fabrication. In manufacturing, regulators support welding, cutting, and pressure testing processes, particularly in automotive and shipbuilding industries. The oil and gas sector uses regulators for high-pressure gas handling in exploration, refining, and pipeline testing. In medical applications, regulators deliver precise gas flows for oxygen therapy and laboratory diagnostics.Vietnam’s regulatory environment emphasizes compliance with international standards like ISO 2503 and ISO 5171, ensuring that gas regulators meet global safety and performance criteria. The country’s focus on sustainable development and industrial modernization further drives demand for reliable, cost-effective regulators like single-stage models, which are ideal for applications where constant pressure stability is not critical. As Vietnam continues to expand its industrial base, the need for high-quality gas regulators is set to increase.

Single-Stage High-Pressure Gas Regulator Suppliers in Vietnam

Vietnam hosts a growing number of suppliers and distributors of single-stage high-pressure gas regulators, catering to both domestic and international markets. While local manufacturing is limited, many suppliers partner with global brands to distribute high-quality regulators. Below are notable suppliers and their offerings:

- RS Components Vietnam (rs-online.vn)

RS Components, a global distributor with a presence in Vietnam, offers the GCE Unicontrol single-stage regulator, designed for robustness and safety. Compliant with ISO 2503, these regulators feature a brass body with a corrosion-resistant zinc die-cast bonnet, dual 63 mm gauges, and an integrated pressure relief valve. They are ideal for industrial applications like welding and cutting, with inlet pressures up to 300 bar and outlet pressures tailored to specific gases. RS Components provides reliable delivery and technical support, making it a trusted choice for Vietnamese industries.

- Techman Systems Vietnam (exlok.in)

Techman Systems, an exporter and supplier, offers a range of single-stage high-pressure regulators, including models for corrosive gases like ammonia. Their regulators feature SS 316 bodies with stainless steel diaphragms, supporting inlet pressures up to 280 bar and outlet pressures up to 200 bar. These are designed for applications in oil and gas, pharmaceuticals, and petrochemicals, with features like purge valves for safe handling of reactive gases. Techman emphasizes compliance with industrial standards and offers customized solutions for Vietnam’s industrial needs.

- PCI Analytics Vietnam (pcianalytics.in)

PCI Analytics supplies single-stage regulators like the TXC Series for corrosive gases (e.g., HCl, Cl2, NH3) with inlet pressures from 150 bar to 10 bar and outlet pressures from 10 bar to 2 bar. These regulators include inlet/outlet gauges, ball valves, and optional safety relief valves, making them suitable for laboratory and industrial applications. Their cost-effective design and compatibility with corrosive gases cater to Vietnam’s growing chemical and biotech sectors.

- International Distributors (e.g., Harris, MATHESON)

Global brands like Harris Products Group and MATHESON distribute single-stage regulators in Vietnam through local partners. The Harris Model 3500, designed for high-pressure, high-flow applications, supports manifold systems and industrial tasks with inlet pressures up to 300 bar. MATHESON offers brass and stainless steel single-stage regulators for general-purpose and high-purity applications, ideal for Vietnam’s electronics and laboratory sectors. These brands ensure compliance with standards like ISO 5171 and provide robust technical support through local distributors.

- Local Distributors and Importers

Vietnam’s market includes local distributors importing regulators from brands like APTech, Swagelok, and Rotarex. For example, the Rotarex TGD250 single-stage regulator, designed for high-flow industrial applications, is distributed in Vietnam for welding and manufacturing. These distributors often provide tailored solutions, ensuring compatibility with local cylinder standards and gas types.

These suppliers offer a range of single-stage regulators, from general-purpose brass models to specialized stainless steel units for corrosive or high-purity gases. Many provide customization options, such as specific inlet/outlet connections or flow rates, to meet Vietnam’s diverse industrial requirements. Compliance with standards like ISO 2503 and RoHS ensures safety and reliability.

Choosing the Right Supplier in Vietnam

Selecting the right single-stage high-pressure gas regulator supplier in Vietnam requires careful consideration of several factors:

- Quality and Certifications: Choose suppliers offering regulators compliant with ISO 2503, ISO 5171, or RoHS standards to ensure safety and performance. Certified products, like those from RS Components or PCI Analytics, are rigorously tested for reliability.

- Material and Gas Compatibility: Ensure the regulator’s materials (e.g., brass for non-corrosive gases, stainless steel for corrosive gases) match your application. Suppliers like Techman Systems offer SS 316 regulators for ammonia or chlorine, ideal for chemical industries.

- Local Support and Availability: Opt for suppliers with a strong presence in Vietnam, such as RS Components, for faster delivery and technical support. Local expertise is crucial for addressing installation and maintenance needs.

- Customization and Application Fit: Select suppliers offering tailored solutions, such as regulators with specific pressure ranges or purge valves for corrosive gases. Companies like PCI Analytics provide customizable options for laboratory and industrial use.

- Cost-Effectiveness: Single-stage regulators are generally more affordable than dual-stage models, making them attractive for cost-conscious applications. Compare pricing from suppliers like Techman and local distributors to balance quality and cost.

Businesses should also prioritize suppliers with robust after-sales services, including maintenance and calibration support, to ensure long-term performance. Consulting with suppliers to match regulators to specific gases and applications can optimize operational efficiency.

Conclusion

Single-stage high-pressure gas regulators are vital for Vietnam’s growing industrial sectors, providing cost-effective and reliable solutions for controlling gas flow in applications like welding, electronics, oil and gas, and medical diagnostics. Suppliers like RS Components, Techman Systems, and PCI Analytics, along with distributors of global brands like Harris and MATHESON, offer high-quality regulators that meet international standards. By prioritizing quality, compatibility, and local support, businesses can select the right supplier to enhance safety and efficiency. As Vietnam continues to industrialize, the demand for single-stage regulators will grow, making trusted suppliers key partners in the nation’s economic progress.

For more about the single stage high pressure gas regulators supplier in vietnam, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

How Does a 316 Stainless Steel Pipe Fitting Work?

A Comprehensive Guide to 316L VIM VAR UHP Gas Regulator

Tags

Recommended Products

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

Stainless Steel High Purity High Temperature Pneumatic Actuated Ball Valves JBV2 Series

-

766L High Purity Female Connector UHP Fitting Female Connector

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

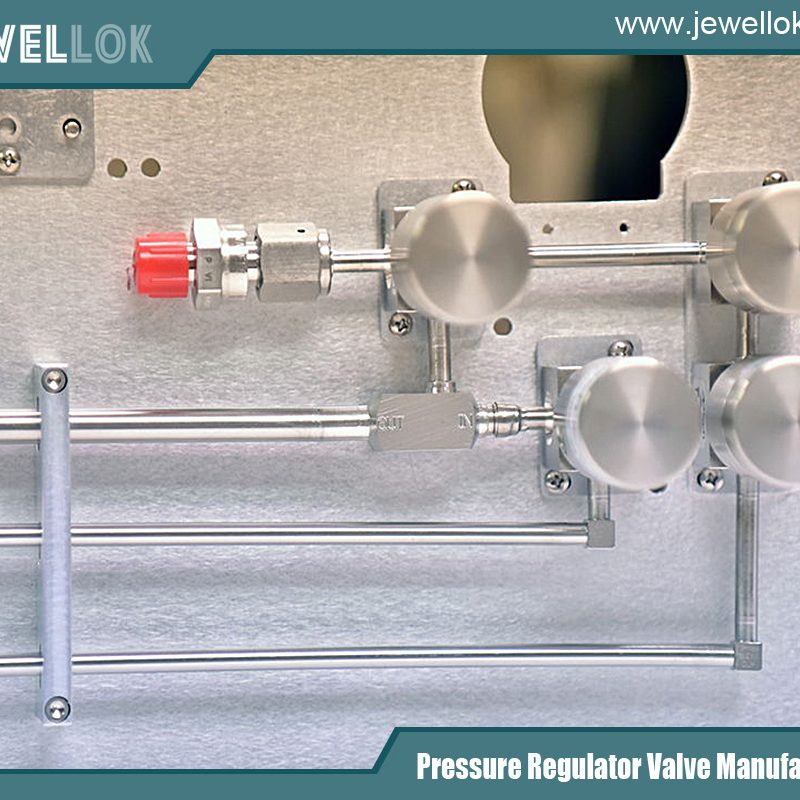

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor