Blog

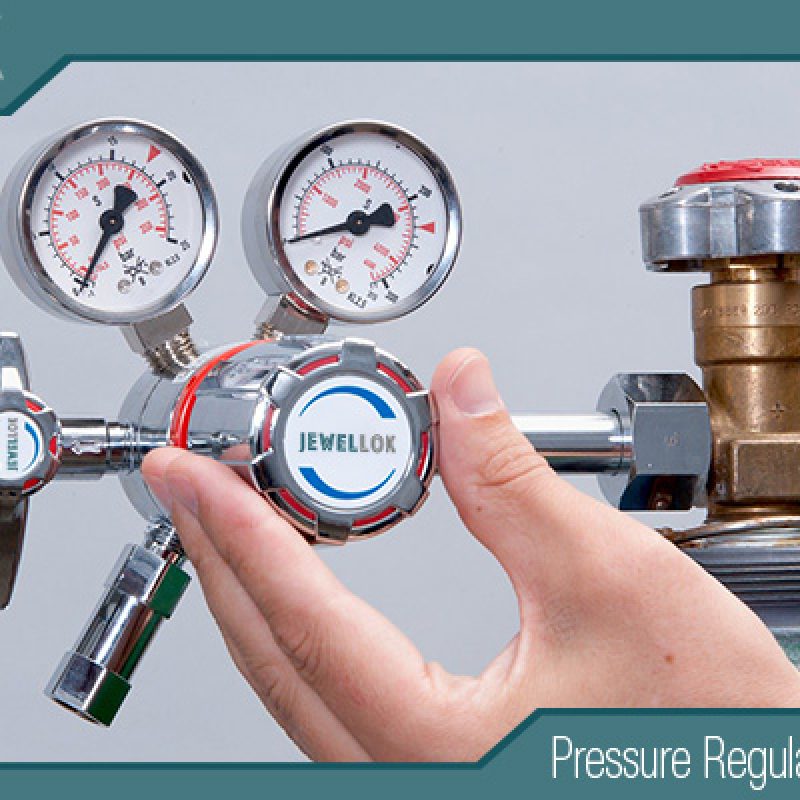

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Troubleshooting Common Issues in Helium Gas Changeover Manifold Systems

- Pressure Regulator Valve Manufacturer

- 0-100 PSI Helium Tank Regulator, Acetylene Gas Changeover Manifold, acetylene gas changeover manifold work, Adjustable Helium Single Stage High Pressure Gas Regulator, argon gas changeover manifold, Argon Gas Changeover Manifold Manufacturer, argon gas changeover manifold supplier, Auto Gas Changeover Manifold System, Automatic gas changeover manifold, Balbula sa diaphragm nga gisulayan ang pagtulo sa helium, best gas changeover manifold, Best gas changeover manifold for laboratories, bulk helium in thailand, BURSAN Gas Changeover Manifold, Carbon Dioxide Gas Changeover Manifold, CO2 gas changeover manifold, gas changeover manifold, gas changeover manifold supplier philippines, gas manifold system, Helium Argon Gas Changeover Manifold, Helium Bottle and Cylinder Regulators, helium gas changeover manifold, helium gas changeover manifold manufacturer, helium gas changeover manifold supplier philippines, helium gas changeover manifold systems, helium gas pressure regulator, Helium Gas Regulators, Helium High Pressure Regulator, hydrogen manifold, hydrogen valve manifold, nitrogen cylinder manifold, nitrogen gas changeover manifold, nitrogen gas manifold system, oxygen gas changeover manifold, oxygen gas changeover manifold supplier, oxygen gas changeover manifold supplier philippines, oxygen manifold system, propane manifold with valves

- No Comments

Troubleshooting Common Issues in Helium Gas Changeover Manifold Systems

Helium gas changeover manifold systems are critical components in laboratories, analytical facilities, semiconductor fabrication, and medical imaging centers, ensuring a continuous, high-purity supply of this essential, finite resource. System failures can lead to costly downtime, compromised data integrity, and safety hazards. This article provides a structured troubleshooting methodology for the most common issues encountered in these systems, focusing on pressure irregularities, leaks, automatic changeover failures, and contamination. A blend of proactive maintenance strategies and reactive diagnostic steps is outlined to maximize system reliability and safety.

- The Critical Role of Helium Gas Changeover Manifolds

Helium, with its unique properties of inertness, high thermal conductivity, and small atomic size, is indispensable for applications such as Gas Chromatography (GC), GC-Mass Spectrometry (GC-MS), MRI cooling, and leak detection. Given its high cost and supply volatility, efficient utilization is paramount. A changeover manifold system typically consists of two or more helium gas cylinders (often a “primary” and a “secondary” or “bank” of cylinders), connected via high-pressure tubing to a manifold frame equipped with pressure regulators, valves, a pressure-switching device, and an outlet regulator delivering gas at a consistent pressure and flow to the point of use.

The primary function is automatic or manual switching from a depleted cylinder to a full one without interrupting the gas supply. This seemingly simple operation belies a complex interplay of mechanical, pneumatic, and sometimes electronic components, each a potential point of failure. Effective troubleshooting requires a systematic approach, an understanding of the system’s design, and a rigorous adherence to safety protocols, as these systems operate at high pressures (up to 3000 psi / 207 bar for full cylinders).

- Foundational Safety and Preparatory Steps

Before initiating any troubleshooting:

- Personal Protective Equipment (PPE): Always wear safety glasses with side shields and heavy-duty gloves.

- Ventilation: Ensure the area is well-ventilated. While helium is non-toxic, it can act as a simple asphyxiant by displacing oxygen.

- System Knowledge: Consult the manufacturer’s manuals for specific diagrams, pressure ratings, and part numbers.

- Pressure Relief: Isolate and depressurize the downstream system and relevant sections of the manifold before inspecting or replacing any component. Use the appropriate vent or purge valve.

- Leak Detection: Have a certified helium leak detector or a compatible leak detection solution (soapy water formulated for high-pressure gas, never household soap) ready.

- Common Issue 1: Irregular or Loss of Output Pressure

Symptoms: Downstream instruments report low carrier gas pressure, inconsistent baseline, or fail to maintain set flow rates. The system alarm for low pressure may activate.

Troubleshooting Steps:

- Check Primary Supply: Verify the pressure on the cylinder(s) currently in service. A cylinder reading near zero is simply empty—initiate a manual changeover. Do not assume automatic switching has occurred.

- Inspect the Changeover Mechanism:

- For Mechanical (Pressure-Sensor) Switches: These use a piston or diaphragm that actuates a valve. If the primary supply is depleted but switching hasn’t occurred, the sensing mechanism may be fouled with particulate matter or failed. Gently tap the switch body; sometimes a stuck piston can be freed. Depressurize the system and inspect/clean or replace the switch unit as per manual.

- For Electronic Switches: Check for power to the unit. Verify the set-points for switchover pressure. Are the electronic pressure transducers reading correctly? A faulty sensor or solenoid valve can prevent activation.

- Examine Regulators: The two-stage regulator on the manifold outlet is a common failure point.

- Creep: If the outlet pressure slowly rises over time with no demand, the regulator’s seat is likely damaged. This requires replacement of the regulator or its internal seat kit.

- Droop/Sag: If pressure falls under constant flow, the regulator may be undersized for the demand or failing. Test by closing the downstream valve; if pressure recovers, the regulator is functioning but may be at its flow limit.

- Lock-up: Failure to achieve set pressure. The diaphragm may be ruptured, or the spring damaged.

- Verify Downstream Flow and Blockages: Close the outlet valve at the manifold. If output pressure recovers and holds, the problem is downstream—a fully open instrument valve, a cracked liner, or a leak in the GC system. If pressure does not recover, the issue is within the manifold.

- Common Issue 2: Gas Leaks

Symptoms: Unexpectedly rapid cylinder depletion (much faster than historical usage rates), audible hissing (in severe cases), or detection by a leak checker.

Troubleshooting Steps (conduct with system pressurized):

- High-Pressure Connections (Cylinder to Manifold): These CGA (Compressed Gas Association) fittings are the most common leak sources. Use a leak detection solution on:

- The cylinder valve stem.

- The nut/ferrule connection at the manifold inlet.

- The purge/vent valve stems. Bubbles will indicate a leak. Tighten cautiously—over-tightening can gall or crack brass ferrules. The rule is “finger-tight plus a quarter to a half turn with a wrench.”

- Low-Pressure Connections (Manifold Outlet): Check all tubing connections (Swagelok, VCR, etc.) leading to the instrument. Ensure ferrules are not over-used and are properly seated.

- Internal Manifold Leaks: Faulty valves or regulators can leak internally from the high-pressure to the low-pressure side, venting gas through the regulator vent hole. This is often detected as a constant, low hiss from the regulator body and confirmed by capping the vent and seeing pressure build. This requires regulator service.

- Leak at the Changeover Valve: The seal within the automatic changeover valve can wear. Testing this requires isolating sections of the manifold and pressure testing them separately.

- Common Issue 3: Failure of Automatic Changeover

Symptoms: System runs the primary cylinder completely empty, causing instrument failure, before an operator manually switches to the secondary supply.

Troubleshooting Steps:

- Verify Secondary Supply: Ensure the secondary cylinder(s) are open and have adequate pressure. An automatic system cannot switch to an empty or closed bank.

- Check Valve Status: On some manifolds, manual shut-off valves for each bank must be in the correct position (both open) for automatic operation. Confirm this.

- Test the Changeover Switch Point:

- Mechanical Switches: The switch point is often adjustable (e.g., 200 psi). With the system online, slowly close the primary cylinder valve. Observe the pressure gauge for the primary bank. At the designated pressure, you should hear a distinct “clunk” as the switch occurs and the primary gauge drops to zero. If it doesn’t switch, the mechanism is faulty.

- Electronic Switches: Simulate the same test. Does the electronic display show the dropping pressure? Does the status LED change? Does the solenoid “click”? Failure could be in the sensor, control logic, or solenoid valve. Check all electrical connections.

- Inspect for Sticking Components: Particulate contamination from cylinder gas (rare but possible) or degraded diaphragm materials can cause valves or pistons to stick. Periodic purging of the manifold can help prevent this.

- Common Issue 4: Gas Purity and Contamination Problems

Symptoms: Increased baseline noise, ghost peaks, or poor sensitivity in GC/MS applications. Frequent filament burn-out in MS detectors.

Troubleshooting Steps:

- Source of Contamination: The first suspect is the gas source itself. Install a new, certified high-purity helium cylinder to rule this out.

- Inadequate Purging: After a cylinder change, the manifold and all connecting lines must be purged thoroughly to remove atmospheric gases (oxygen, nitrogen, moisture) that were introduced during the changeover. Follow a proper purge procedure: crack the cylinder valve, purge the high-pressure connector, connect to the manifold, open fully, and use the manifold’s purge valve to vent for several minutes at a high flow rate before supplying the instrument.

- Internal Manifold Contamination: Moisture or air can be drawn into the manifold through a microscopic leak when the system is off and under vacuum (e.g., from an instrument pump). Pressure the system and check for leaks as in Section 4.

- Failed or Absent Filtration: Most high-purity applications require in-line purifiers (oxygen/moisture traps, hydrocarbon traps) placed after the manifold outlet. If problems arise, check the purifier’s lifespan indicator or replace it proactively. Ensure the correct type of purifier is used for the contaminant of concern.

- Proactive Maintenance: The Best Form of Troubleshooting

A preventative maintenance schedule can avert 90% of common issues:

- Daily/Weekly: Log cylinder pressures. Visually inspect for obvious leaks, damage, or corrosion.

- Monthly: Perform a comprehensive leak check on all fittings. Verify automatic changeover function by simulating a primary cylinder empty condition.

- Every 6 Months: Replace outlet gas filters/purifiers on a schedule, not just when problems appear. Check and clean regulator vents.

- Annually: Consider professional calibration and inspection of regulators and switches. Replace all sealing components (O-rings, gaskets) in the manifold as recommended by the manufacturer.

- At Cylinder Change: Always use new crushable seals (BOSS™ seals) on CGA connections. Never use Teflon tape on high-pressure gas fittings.

- Conclusion

Troubleshooting a helium changeover manifold system is a methodical process of elimination, starting from the gas source and moving downstream to the point of use. The most frequent culprits are simple: empty cylinders, insufficient purging, and leaks at connections. However, understanding the failure modes of more complex components like pressure switches and two-stage regulators is key to resolving persistent issues.

Investing time in operator training on correct cylinder handling, changeover procedures, and leak checking is invaluable. Furthermore, establishing and adhering to a rigorous preventative maintenance program is the single most effective strategy to ensure a continuous, pure, and safe supply of helium, thereby protecting sensitive instrumentation, valuable data, and operational continuity. In an era of helium conservation, a well-maintained manifold system is not just a technical necessity but also an economic and environmental imperative.

For more about troubleshooting common issues in helium gas changeover manifold systems, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

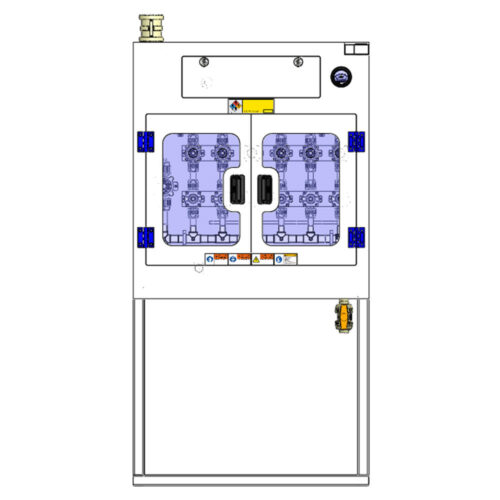

VMB Valve Manifold Box And Panel Gas Cabinet, BSGS Gas Cabinets, TMA Gas Cabinets, Scrubber Tail Gas Treatment Cabinets

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

771L Male Run Tee | Stainless Steel High Quality High Purity Male Run Tee Branch Tee Pipe Fittings