Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Troubleshooting Valve Manifold Box Issues: A Systematic Guide for Maintenance Professionals

- Pressure Regulator Valve Manufacturer

- argon gas regulator, Argon Gas Regulator Manufacturer, argon gas regulator work, Back Pressure Regulating Valve, back pressure regulator manufacturers, best high purity gas pressure regulator, best high purity gas pressure regulators manufacturer, best high purity gas pressure regulators manufacturers USA, Brass Pressure Regulator, gas regulator valve manufacturers, gas valve manifold box, high purity valves manufacturers, high-pressure argon gas regulator, high-pressure argon gas regulator manufacturer, high-pressure argon gas regulator supplier, high-pressure argon gas regulator work, industrial diaphragm valve manufacturers, low pressure valve manufacturer, medical oxygen pressure gauge manufacturer, needle valve 10000 psi manufacturer, nitrogen manifold panel for individual gas cabinet and valve manifold box, pneumatic actuated ball valve manufacturer, Pressure Argon Gas Regulator, pressure control valve manufacturers, pressure gauge manufacturers, pressure reducing valve manufacturers, pressure relief valve manufacturers, semiconductor valve manifold box, semiconductor valve manifold box diaphragm valves, semiconductor valve manifold box gas pressure regulators, SiH4 NF3 NH3 Gas Valve Manifold Boxes, Sih4 Valve Manifold Box, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer, Stainless Steel Pressure Regulator, Ultra High Purity Gas Valves, valve manifold box, Valve Manifold Box (VMB) gas cabinet, Valve Manifold Box for Gas System VMB, valve manifold box semiconductor, Valve manifold box/panel (VMB/VMP), Valve Manifold Boxes And Panels, VMB Cabinet Gas Valve Manifold Box, vmb valve manifold box

- No Comments

Troubleshooting Valve Manifold Box Issues: A Systematic Guide for Maintenance Professionals

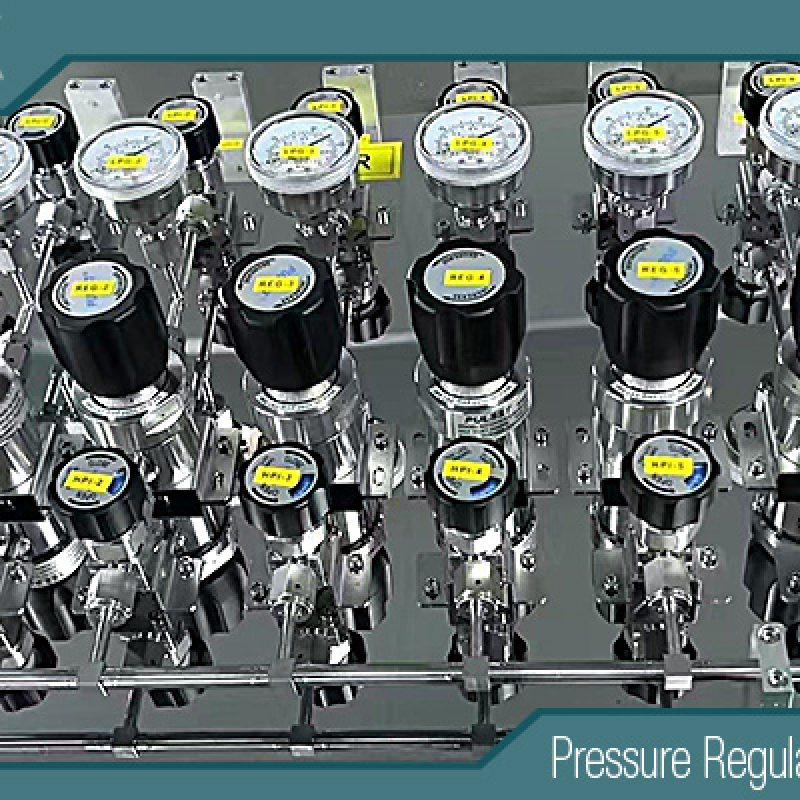

The valve manifold box (VMB), often an unsung hero in industrial process control, serves as the critical interface between field-mounted control valves and the distributed control system (DCS). Its primary functions—air supply distribution, signal conditioning, and safe isolation for maintenance—are fundamental to loop integrity. When a VMB malfunctions, it can manifest as erratic valve behavior, complete loop failure, or even process safety incidents. This technical article provides a comprehensive, systematic framework for diagnosing and resolving common VMB issues, emphasizing a logical progression from external to internal checks and from simple to complex faults.

- The Role of the Valve Manifold Box

Before diving into troubleshooting, it is essential to understand the VMB’s typical composition. A standard assembly for a single-acting, spring-return control valve includes:

- Air Supply Regulator & Filter: Cleans and regulates plant air (e.g., 80-100 psi) to a stable instrument air supply (typically 20-30 psi).

- Gauges: Indicate supply pressure and, often, output pressure to the valve actuator.

- I/P (Current-to-Pressure) Converter: The brain of the assembly. It translates the 4-20 mA DC control signal from the DCS into a proportional 3-15 psi (or 0.2-1.0 bar) pneumatic output signal.

- Volume Booster/Relay (if applicable): Amplifies the I/P’s low-volume output signal to provide high-volume, high-speed air flow for large actuators.

- Manifold Block: A multi-valve assembly (usually 3-valve or 5-valve) allowing for isolation, venting, and equalization to facilitate valve removal or calibration.

- Internal Tubing & Fittings: Connects all components.

Failure in any component can degrade performance. A systematic approach prevents misdiagnosis and unnecessary parts replacement.

- The Troubleshooting Methodology: A Step-by-Step Framework

Adhere to a safe work permit (isolate permit, LOTO) before any physical intervention. The guiding principle is: Observe, Isolate, Diagnose.

Step 1: Define the Symptom Precisely

- “The valve won’t move.” Is it stuck at 0%, 100%, or an intermediate position?

- “The valve is oscillating/hunting.” Is it erratic or following process noise?

- “The valve is slow to respond.” Is the slowness in one direction or both?

- “There’s a continuous air leak.” Is it from a vent port, gauge, or fitting?

Correlate the symptom with DCS trends, operator logs, and process upsets.

Step 2: Preliminary External Checks

- Electrical Integrity: Verify the 4-20 mA signal at the VMB terminals using a precision multimeter. Is the signal present, stable, and correlating with the DCS output? A missing or frozen signal points to a DCS, wiring, or safety barrier issue, not the VMB.

- Air Supply Integrity: Check the supply pressure gauge. Is it at the set value (e.g., 30 psi)? Is it stable or dropping? A low or zero supply pressure indicates a problem upstream (blocked filter, failed plant air, shut-off valve closed).

- Physical Inspection: Look for obvious damage, corrosion, ice formation (in cold climates), oil or water contamination in sight glasses, and listen for audible hissing from vents or leaks.

Step 3: Isolating the Fault within the VMB

This is where the manifold’s design becomes instrumental.

- Using a 5-Valve Manifold:

- For a “valve stuck” issue, carefully operate the manifold valves to isolate the field valve. Put the assembly in Calibrate mode (Block valve closed, Vent/Equalize valve open to vent the output). Now, the I/P’s output is vented to atmosphere.

- Apply a known 4-20 mA signal from a calibrator to the I/P input. Does the I/P output pressure change smoothly and proportionally? If YES, the VMB is functioning, and the fault lies in the field valve or its actuator. If NO, the fault is within the VMB.

- Using a 3-Valve Manifold: The procedure is similar, though the vent path may be less direct. Isolate the field valve and vent the output line.

- Diagnosing Common Component Failures

Once the fault is isolated to the VMB, proceed with component-level diagnosis.

- I/P Converter Failures

The I/P is the most common failure point.

- Symptoms: No output pressure change, erratic output, output “saturated” at high or low pressure, zero or span shift.

- Diagnosis:

- Perform a Static Test: With output vented, apply 4, 12, and 20 mA signals. The output should be approximately 3, 9, and 15 psi respectively. Nonlinearity or failure to track indicates I/P failure.

- Check for Internal Leaks: With the I/P energized and output blocked, does the output pressure hold steady or bleed down? A bleed down suggests a leaking internal nozzle/flapper assembly.

- Check the Feedback Sensor/Wire: Many modern I/Ps have internal piezoelectric or capacitive feedback sensors. Failure here causes loss of control.

- Check Zero and Span Adjustments: Only adjust if authorized and with a calibrator. Gradual drift may require re-calibration; sudden failure indicates component replacement.

- Air Supply Regulator/Filter Issues

- Symptoms: Low or fluctuating supply pressure, slow valve response (especially on opening, if spring-return), wet or oily air downstream.

- Diagnosis:

- Monitor the Supply Gauge: If pressure drops when the I/P output changes, the regulator cannot keep up with demand. This is a classic sign of a failing regulator or a severely clogged filter.

- Bypass the Regulator (Temporarily & Cautiously): If safe for the I/P (check its max supply rating), connect clean, regulated air directly to the I/P supply port. If operation returns to normal, the regulator/filter assembly is faulty.

- Drain the Filter: Automatic drains can fail. Manually drain to check for excessive liquid.

- Volume Booster/Relay Malfunctions

- Symptoms: Very slow valve actuator movement in one direction (typically when filling the actuator), but normal speed in the other (spring-return exhaust). Asymmetric response.

- Diagnosis:

- Swapping Test: If the booster is a simple 1:1 relay, swap the supply and output connections at its ports (if design allows). If the slowness direction reverses, the booster is likely clogged or damaged.

- Leakage Test: A leaking booster diaphragm will cause a continuous, often small, air consumption and may prevent the actuator from holding position.

- Check the Restrictor: Some boosters have an adjustable restrictor (needle valve) on the pilot or exhaust. An incorrectly set or clogged restrictor causes speed issues.

- Manifold Block and Tubing Leaks

- Symptoms: Continuous air consumption (hissing), inability to hold actuator pressure, slow drift of valve position.

- Diagnosis:

- Soap Solution Test: The classic method. Apply a soapy water solution to all fittings, manifold seals, valve stems, and gauge connections. Look for bubbles.

- Pressure Decay Test: Isolate sections of the assembly, apply pressure, and monitor for drops. Start at the supply inlet with the regulator isolated, then move downstream.

- Manifold Valve Seals: The seals (O-rings, gaskets) on the block/vent/equalize valves wear over time and cycles, leading to internal cross-port leaks.

- Gauge Inaccuracy

- Symptoms: Misleading readings. A faulty gauge can send you on a wild goose chase.

- Diagnosis: Cross-reference with a trusted test gauge connected to the same pressure point. Never assume a panel gauge is 100% accurate.

- Special Considerations and Advanced Diagnostics

- Stiction and I/P Resolution: For slow processes, a high-resolution I/P is critical. A low-resolution I/P can cause “jumpy” valve movement. Check manufacturer specs.

- Moisture and Contamination: This is a root cause, not a symptom. Water or oil can foul the I/P’s nozzle, clog booster relays, and degrade regulator performance. Always trace contamination to its source (inadequate air drying, compressor oil carryover).

- Electrical Noise and Grounding: Erratic I/P behavior can be caused by electromagnetic interference (EMI) or poor grounding. Ensure shield wires are properly terminated and the 4-20 mA signal is clean when viewed on an oscilloscope.

- Ambient Temperature Effects: Extreme heat can affect electronic components in the I/P. Extreme cold can freeze moisture in lines. Consider housing insulation or heat tracing.

- Preventive Maintenance: Avoiding Future Issues

A proactive strategy minimizes unplanned downtime.

- Regular Inspection Schedule: Visually check for leaks, gauge integrity, and supply pressure monthly.

- Calibration Cycle: Include the entire VMB (I/P, gauges) in the plant’s annual or biennial calibration schedule. Calibrate under simulated load if possible.

- Air Quality Management: Ensure instrument air dryers and coalescing filters upstream are maintained. Install and service point-of-use filters in the VMB.

- Spare Parts Strategy: Keep critical spares (I/P converters, regulator kits, manifold seals) on hand. Consider standardized I/P models across the plant.

- Conclusion

Troubleshooting a valve manifold box is a logical process that combines an understanding of its function with a disciplined diagnostic approach. By starting with external signal and supply verification, using the manifold to isolate the field device, and then methodically testing individual components, technicians can accurately identify the root cause. Remember that the VMB is a system; a failure in the air supply can look like an I/P fault, and a leaking field actuator can appear as a VMB issue. By incorporating the preventative measures outlined, the reliability of these critical control interfaces can be significantly enhanced, ensuring stable and safe process operation.

The skilled troubleshooter respects the VMB not just as a collection of fittings, but as a precision pneumatic computer whose health is directly proportional to loop performance.

For more about troubleshooting valve manifold box issues: a systematic guide for maintenance professionals, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

BSGS Large Flow Specialty Gas Supply Cabinet 3 Cylinder Gas Storage Cabinet Fully Automated PLC Control Bulk Specialty Gas Systems (BSGS) Gas Cabinets