Blog

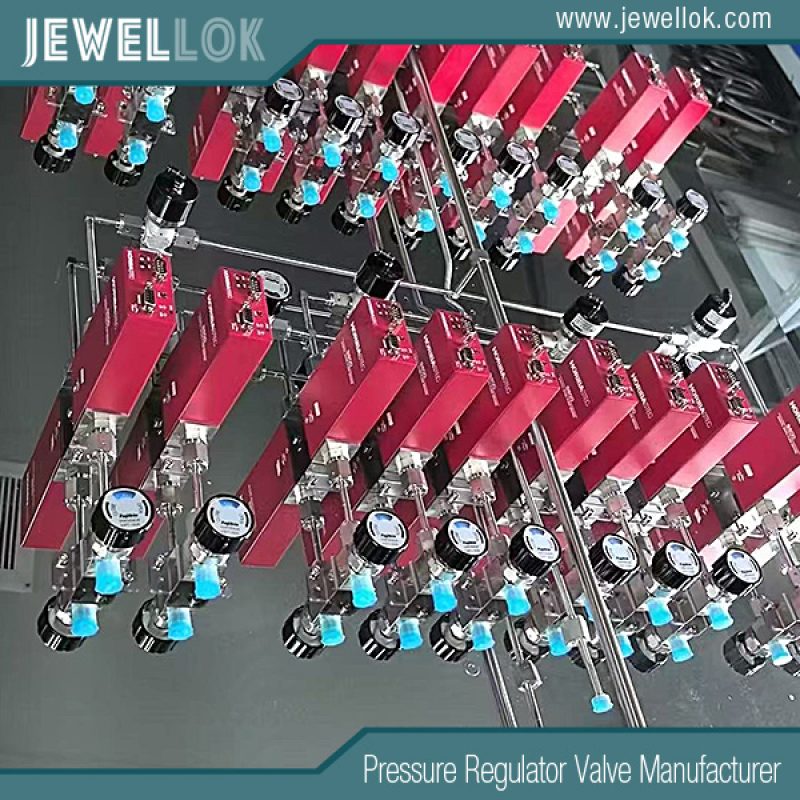

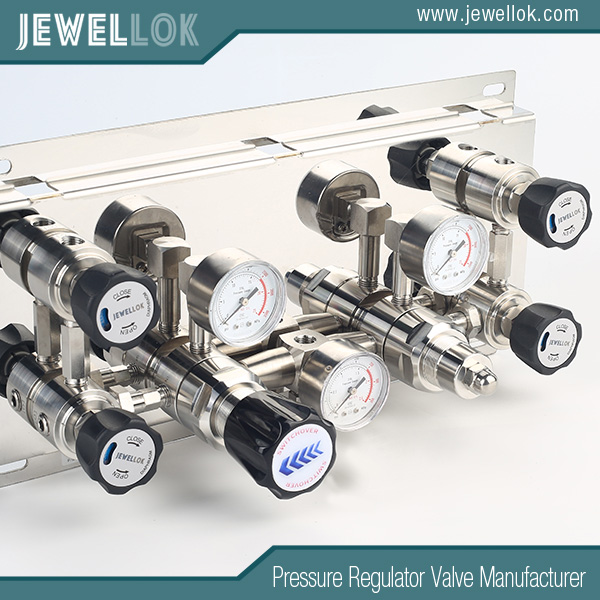

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

UHP 316L Stainless Steel Gas Pressure Regulators Manufacturer in Thailand

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, 316L Stainless Steel Gas Pressure Regulators, BA Grade High Purity Gas Pressure Regulators, back pressure regulator manufacturers, best high purity gas pressure regulators manufacturer, china high pressure air regulator valve manufacturer, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, gas pressure regulators, Gas Pressure Regulators Manufacturers in India, gas regulator valve manufacturers, Helium Gas Pressure Regulators, high flow needle valve manufacturer, high pressure ball valve manufacturer, high pressure hydraulic needle valve manufacturer, high pressure needle valve manufacturer, high purity valves manufacturers, High-Flow Manual Gas Pressure Regulators, Hydrogen Gas Pressure Regulators, industrial diaphragm valve manufacturers, low pressure valve manufacturer, medical oxygen pressure gauge manufacturer, pneumatic actuated ball valve manufacturer, pressure control valve manufacturers, pressure gauge manufacturers, pressure reducing valve manufacturers, pressure relief valve manufacturers, semiconductor valve manifold box gas pressure regulators, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer, Stainless Steel Gas Pressure Regulators, Stainless Steel Pressure Regulator, UHP 316L Gas Pressure Regulators, UHP 316L Pressure Regulators, uhp 316l stainless steel gas pressure regulators, UHP Gas Pressure Regulators, UHP Regulators for Semiconductor, UHP Stainless Steel Gas Pressure Regulators

- No Comments

UHP 316L Stainless Steel Gas Pressure Regulators Manufacturer in Thailand

Ultra-high purity (UHP) 316L stainless steel gas pressure regulators are precision-engineered components designed to control gas pressure in applications requiring exceptional cleanliness, corrosion resistance, and reliability. These regulators are critical in industries such as semiconductor manufacturing, pharmaceuticals, and specialty gas processing, where even trace contaminants can compromise product quality or safety. Thailand, a rapidly industrializing nation with a growing presence in high-tech manufacturing, is positioning itself as a hub for advanced industrial components in Southeast Asia. This article examines the significance of UHP 316L stainless steel gas pressure regulators, the current state of manufacturers in Thailand, and the technical and logistical considerations for sourcing these specialized devices. It aims to provide actionable insights for businesses navigating Thailand’s emerging market for high-purity gas equipment.

The Role and Importance of UHP 316L Stainless Steel Gas Pressure Regulators

UHP gas pressure regulators are designed to manage gas pressure with extreme precision, reducing high inlet pressures (often up to 3000 psig or 20,684 kPa) to stable, lower outlet pressures suitable for sensitive applications. Unlike standard regulators, UHP models are built to minimize particle generation, resist corrosion, and ensure leak-tight performance, making them ideal for handling specialty gases like hydrogen, nitrogen, or argon. The use of 316L stainless steel—a low-carbon, molybdenum-alloyed grade—enhances corrosion resistance and compatibility with dry corrosive gases, such as hydrogen, which can embrittle other materials.

These regulators are indispensable in industries where purity is paramount. In semiconductor manufacturing, for instance, UHP regulators ensure that gases used in wafer fabrication remain free of contaminants that could affect chip performance. In pharmaceuticals, they support sterile environments by maintaining clean gas delivery systems. As Thailand expands its role in these high-tech sectors, the demand for UHP 316L stainless steel gas pressure regulators is growing, underscoring the need for reliable manufacturers and suppliers.

Thailand’s Industrial and High-Tech Landscape

Thailand is a key player in Southeast Asia’s industrial economy, with a strong manufacturing base in electronics, automotive, and chemical processing. The country is one of the world’s leading producers of hard disk drives and a significant hub for semiconductor assembly and testing. Its Eastern Economic Corridor (EEC) initiative, launched to attract high-tech industries, has spurred investments in advanced manufacturing, including facilities requiring UHP gas systems. Additionally, Thailand’s energy sector is evolving, with increasing interest in renewable energy and hydrogen as part of its National Energy Plan, which aims for carbon neutrality by 2050.

The growth of these industries drives demand for specialized equipment like UHP gas pressure regulators. However, Thailand’s manufacturing sector for such niche components is still developing, with many businesses relying on imports from countries like China, Japan, or the United States. This creates both challenges and opportunities for local manufacturers to enter the market and meet the needs of Thailand’s high-tech industries.

The Need for Reliable Manufacturers in Thailand

The demand for UHP 316L stainless steel gas pressure regulators in Thailand highlights the need for a robust supply chain. These regulators must meet stringent standards, such as those outlined in the European Pressure Equipment Directive (PED) or ISO certifications, to ensure safety and performance in high-purity applications. Key requirements include low particle generation, high cycle life, and compatibility with extreme conditions, such as high pressures or corrosive gases.

Currently, Thailand has limited domestic manufacturers specializing in UHP gas pressure regulators. Companies like Shenzhen Jewellok Technology Co., Ltd. (China) and Nai Lok Industrial Co., Ltd. (China) dominate the global market for UHP regulators, offering products made with 316L stainless steel and electropolished to a 5Ra surface finish for maximum cleanliness. While these firms serve Thailand through exports, the lack of local production can lead to challenges like long lead times, high shipping costs, and limited after-sales support. Establishing or expanding local manufacturing could address these issues, providing Thai industries with faster access to high-quality regulators tailored to their needs.

Leveraging Global and Local Marketplaces for Sourcing

Given the scarcity of local manufacturers, Thai businesses often turn to global B2B platforms like Hyfindr or Nai Lok’s online catalog to source UHP 316L stainless steel gas pressure regulators. These platforms offer a range of products, including single-stage and dual-stage regulators, with detailed specifications, certifications, and supplier contacts. For example, Nai Lok provides UHP regulators with 316L stainless steel construction, designed for high-pressure to low-pressure regulation in semiconductor and medical applications.

Locally, Thailand’s industrial ecosystem is supported by organizations like the Thailand Board of Investment (BOI), which promotes investment in high-tech manufacturing. Trade shows such as Manufacturing Expo Thailand and InterPlas Thailand provide platforms for connecting with suppliers and exploring advancements in gas handling technologies. These events can help businesses identify potential local or regional manufacturers, fostering partnerships to strengthen Thailand’s supply chain.

Technical Considerations for Selecting UHP 316L Stainless Steel Gas Pressure Regulators

Selecting the appropriate UHP gas pressure regulator requires careful evaluation of technical specifications to ensure compatibility, safety, and performance. Key considerations include:

- Material Compatibility: 316L stainless steel is preferred for its corrosion resistance and low carbon content, which minimizes particle generation and ensures compatibility with corrosive gases like hydrogen. Electropolishing to a 5Ra surface finish further enhances cleanliness.

- Pressure Range: Regulators must handle high inlet pressures (up to 3000 psig or 20,684 kPa) and deliver precise outlet pressures, often as low as 1–10 psig for sensitive applications.

- Flow Capacity: The flow coefficient (Cv) determines the regulator’s ability to supply sufficient gas, critical for high-flow systems like gas cabinets or semiconductor processes.

- Certifications: Compliance with standards like PED, ATEX (for explosive atmospheres), or SEMI (for semiconductor equipment) ensures safety and quality.

- Leak Tightness: UHP regulators require robust seals, often using 316L stainless steel diaphragm valves, to prevent leaks of small-molecule gases like hydrogen.

- Temperature Range: Regulators must operate effectively across a range of temperatures, from cryogenic conditions to high ambient heat, common in industrial settings.

Manufacturers should offer customization options, such as adjustable pressure settings or specific fitting types (e.g., 1/4″ tube fittings), to meet project-specific requirements.

Types of UHP Regulators

Different regulator types suit various applications:

- Single-Stage Regulators: Reduce pressure in one step, suitable for stable inlet pressures.

- Dual-Stage Regulators: Provide greater precision by reducing pressure in two steps, ideal for fluctuating inlet pressures or high-purity applications.

- Dome-Loaded Regulators: Offer high flow and precise control, often used in gas delivery systems for semiconductor manufacturing.

- Pilot-Operated Regulators: Ensure accurate control over wide flow ranges, suitable for complex industrial setups.

Understanding these options helps buyers select regulators aligned with their needs.

Case Study: Sourcing UHP Regulators for a Semiconductor Facility

Imagine a hypothetical scenario where a semiconductor manufacturer in Thailand’s EEC is expanding its facility to produce advanced microchips. The project requires UHP 316L stainless steel gas pressure regulators to control nitrogen and hydrogen flows in its wafer fabrication process. With limited local options, the company explores global suppliers through a platform like Hyfindr and identifies a dual-stage regulator from Nai Lok Industrial, featuring 316L stainless steel construction and a 1/4″ tube fitting compatible with their system. The supplier’s regional distributor in Singapore offers expedited shipping and technical support, ensuring compliance with SEMI standards. This solution allows the company to meet its stringent purity requirements while maintaining project timelines, highlighting the importance of global supply chains in Thailand’s high-tech sector.

Future Outlook for UHP Regulators in Thailand

Thailand’s ambition to become a high-tech manufacturing hub, coupled with its focus on renewable energy and hydrogen, suggests a promising future for the UHP gas pressure regulator market. As the EEC attracts more semiconductor and pharmaceutical investments, demand for UHP components will grow. This trend could encourage local manufacturers to develop expertise in producing 316L stainless steel regulators, reducing reliance on imports and fostering a domestic supply chain.

Thailand’s strategic location in Southeast Asia and its trade agreements, such as the ASEAN Free Trade Area, position it as a potential exporter of UHP components to neighboring countries. Investments in research and development, supported by initiatives like the BOI’s incentives for advanced manufacturing, could drive innovation in valve design, such as smart regulators with integrated sensors for real-time monitoring.

Conclusion

The market for UHP 316L stainless steel gas pressure regulators in Thailand is nascent but holds significant potential as the country advances in high-tech and sustainable industries. While local manufacturing is limited, global platforms and regional suppliers provide access to high-quality regulators that meet stringent purity and safety standards. By prioritizing technical specifications and leveraging both local and international resources, Thai businesses can secure the components needed for their applications. As Thailand’s industrial landscape evolves, the development of domestic manufacturing capabilities will be crucial to supporting its growth as a hub for high-purity gas technologies.

For more about UHP 316L stainless steel gas pressure regulators manufacturer in thailand, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

7102L Stainless Steel 316L SS Union Cross Ultra High Purity Long Arm Union Elbow Tee Cross Butt Weld Fittings

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases

-

7121L Plug High Purity Plug Fitting And Blanking Plug

-

Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

Ultra High Purity Stainless Steel Compressed Gas Changeover Manifold Panel System For Integrated Gas Supply System