Blog

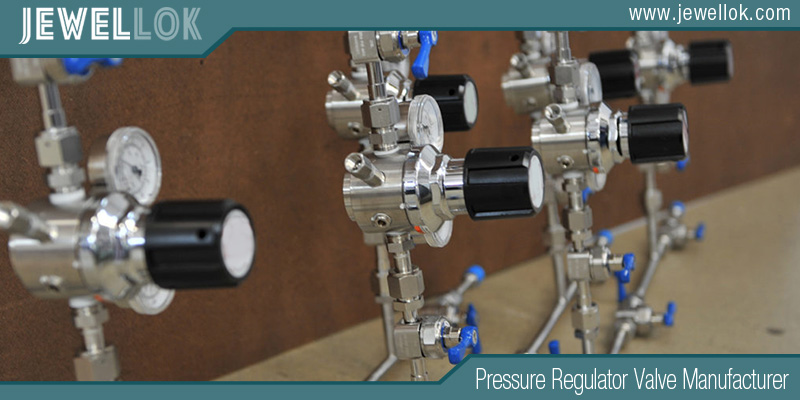

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What is a High Pressure Argon Gas Regulator?

- Pressure Regulator Valve Manufacturer

- 1 2 gas regulator, 1 back pressure regulator, 1 stage regulator, 1/2-inch gas regulators, 2 stage argon regulator, 2 stage nitrogen regulator, 3/4 natural gas regulator, adjustable back pressure regulator, Adjustable Helium Single Stage High Pressure Gas Regulator, adjustable natural gas regulator, argon gas regulator, Argon Gas Regulator Manufacturer, argon regulator with flow meter, automatic back pressure regulator, back pressure controller, back pressure reducing regulator, back pressure reducing valve, back pressure regulator for liquid, best gas regulator in philippines, best gas regulator valve manufacturers, best high pressure nitrogen gas regulator, Dual Flow Argon Regulator, Dual Output Argon Regulator, dual-stage argon regulators, gas back pressure regulator, gas regulator, harris 25gx regulator, high pressure gas regulator, high pressure regulator, high purity argon regulator, high-pressure argon gas regulator, high-pressure argon gas regulator factory, high-pressure argon gas regulator manufacturer, high-pressure argon gas regulator supplier, low pressure back pressure regulator, Pressure Argon Gas Regulator, sanitary back pressure regulator, single stage gas regulator, single stage oxygen regulator, single stage pressure regulator, single stage propane regulator, steam back pressure regulator

- No Comments

What is a High Pressure Argon Gas Regulator?

In the world of industrial gases, precision and safety are paramount. Argon, an inert gas widely used in welding, manufacturing, and scientific applications, is stored in high-pressure cylinders that can reach pressures up to 7500 pounds per square inch (psig) or more. Directly connecting such a cylinder to equipment would be hazardous and inefficient, potentially leading to equipment damage, inconsistent performance, or even explosions. This is where a high-pressure argon gas regulator comes into play—a specialized device designed to reduce and control the gas pressure from the cylinder to a safe, usable level for various applications.

A high-pressure argon gas regulator is essentially a pressure-reducing valve that manages the flow of argon gas from a high-pressure source, such as a compressed gas cylinder, to downstream equipment like welding torches, laboratory instruments, or hydraulic systems. It ensures a consistent delivery pressure and flow rate, preventing fluctuations that could compromise the quality of work or pose safety risks. These regulators are engineered to handle the extreme pressures associated with argon cylinders, which typically operate between 2000 and 4000 psig, and in ultra-high-pressure models, up to 7500 psig. Unlike standard regulators for lower-pressure gases, high-pressure versions incorporate robust materials and designs to withstand these conditions, making them indispensable in fields like TIG (Tungsten Inert Gas) welding, where argon serves as a shielding gas to protect welds from atmospheric contamination.

This article explores the intricacies of high-pressure argon gas regulators in depth. We’ll cover their definition, components, working principles, types, applications, selection criteria, setup procedures, safety considerations, and maintenance tips. By the end, readers will have a comprehensive understanding of these devices, enabling informed decisions for professional or hobbyist use. Drawing from technical guides and product specifications, this explanation emphasizes the balance of mechanical engineering and practical utility that defines these regulators. Whether you’re a welder, lab technician, or engineer, grasping how these regulators function can enhance efficiency and safety in gas-handling operations.

Argon regulators have evolved alongside advancements in gas technology, from basic single-stage models to sophisticated dual-stage units with integrated flowmeters. Their importance cannot be overstated: in welding alone, improper gas regulation can lead to porous welds, oxidation, or unstable arcs, resulting in costly rework or structural failures. In high-stakes environments like aerospace or automotive manufacturing, where argon is used for its inert properties, reliable regulation ensures precision and repeatability.

Basics of Argon Gas and Its Uses

Argon is a colorless, odorless, and non-toxic noble gas that constitutes about 0.93% of Earth’s atmosphere. It is extracted through the fractional distillation of liquid air and compressed into cylinders for industrial use. As an inert gas, argon does not react chemically with other substances under normal conditions, making it ideal for applications requiring a protective atmosphere. In high-pressure cylinders, argon is stored at pressures ranging from 2000 to 6000 psig, depending on the cylinder size and filling standards.

The primary uses of argon include:

- Welding and Metal Fabrication: In TIG and MIG (Metal Inert Gas) welding, argon acts as a shielding gas to prevent oxidation and contamination of the weld pool. It provides a stable arc and smooth bead appearance, essential for materials like stainless steel, aluminum, and titanium.

- Laboratory and Scientific Applications: Argon is used in gas chromatography, plasma etching, and as a carrier gas in spectroscopy due to its inertness.

- Industrial Processes: It fills light bulbs to prevent filament oxidation, purges systems in chemical manufacturing, and is employed in 3D printing for metal additive manufacturing.

- High-Pressure Testing: In aerospace and hydraulics, argon pressurizes systems for testing accumulators, struts, and components under extreme conditions.

Without proper regulation, the high pressure in argon cylinders could overwhelm equipment, leading to leaks, inefficiencies, or hazards. Regulators bridge this gap by delivering gas at controlled pressures, typically 0-50 psig for welding or higher for specialized testing.

What is a Gas Regulator?

Before delving into high-pressure argon specifics, it’s helpful to understand gas regulators in general. A gas regulator is a mechanical device that reduces the high inlet pressure from a gas source (like a cylinder) to a lower, stable outlet pressure suitable for end-use equipment. It maintains this pressure despite variations in cylinder pressure or demand flow rates.

Regulators operate on the principle of force balance, using springs, diaphragms, and valves to control gas flow. They are classified by stages (single or dual), delivery pressure range, and gas compatibility. For inert gases like argon, regulators must be non-reactive and often feature brass or stainless steel construction to prevent corrosion.

A high-pressure argon gas regulator is tailored for argon’s properties and high cylinder pressures. It differs from regulators for reactive gases (e.g., oxygen or CO2) in connection types and materials—argon uses specific CGA (Compressed Gas Association) fittings like CGA-580 to ensure safety and prevent cross-contamination. High-pressure models are built to handle inlet pressures exceeding 3000 psig, with features like self-relieving mechanisms to vent excess pressure safely.

Specifics of High-Pressure Argon Regulators

High-pressure argon regulators are designed for cylinders with pressures up to 7500 psig, far beyond standard welding setups. These are often single-stage or dual-stage units optimized for ultra-high inlet pressures, used in applications like pressure testing or accumulator charging. For instance, models like the Harris HP8700 can deliver precise pressures in demanding environments, featuring brass bodies for durability and urethane diaphragms for flexibility.

In contrast to low-pressure regulators (used post-reduction in pipelines), high-pressure versions connect directly to the cylinder valve. They incorporate safety features like encapsulated seats with filters to protect against contaminants, ensuring longevity and reliability in harsh conditions.

Components of a High-Pressure Argon Gas Regulator

A typical high-pressure argon regulator comprises several key components, each contributing to its functionality:

- Inlet Port/Connection: This threaded fitting (e.g., CGA-580 for argon) attaches to the cylinder valve, handling high inlet pressures. It’s designed to prevent leaks and ensure gas-specific compatibility.

- Body and Bonnet: Made from brass barstock or stainless steel for corrosion resistance and strength. The body houses internal mechanisms, while the bonnet encloses the adjusting spring.

- Pressure Gauges: Dual-scale gauges (e.g., 2.5-inch brass) display inlet (cylinder) pressure and outlet (delivery) pressure in psig/bar. They help monitor gas levels and system performance.

- Diaphragm: A flexible membrane (often urethane or stainless steel) that senses outlet pressure and adjusts the valve. It provides sensitivity to pressure changes for stable regulation.

- Valve Assembly and Seat: The poppet valve and seat (e.g., PCTFE material) control gas flow. An encapsulated design with a 10-micron sintered filter protects against particulate contamination.

- Adjusting Spring and Knob: A coil spring opposes the diaphragm, set via an ergonomic knob for precise pressure adjustment.

- Outlet Port: Connects to hoses or equipment, often with 1/4-inch NPT fittings and stainless steel tubes.

- Safety Features: Self-relieving vents, relief valves, and filters enhance safety by preventing over-pressurization.

These components work in harmony to ensure reliable operation under high pressures.

How It Works: Step-by-Step Mechanism

The operation of a high-pressure argon gas regulator relies on a feedback loop of mechanical forces. Here’s a detailed breakdown:

- Gas Entry: High-pressure argon (up to 7500 psig) enters through the inlet port after the cylinder valve is opened slowly to avoid “slam” (sudden pressure surge).

- Initial Filtration: Gas passes through an internal filter to remove impurities that could damage the seat or diaphragm.

- Pressure Reduction: In a single-stage regulator, gas flows into a chamber where the diaphragm senses outlet pressure. If pressure exceeds the set point (adjusted via the spring-loaded knob), the diaphragm flexes upward, closing the valve to restrict flow. Conversely, if pressure drops (due to demand), the spring forces the diaphragm down, opening the valve to allow more gas.

- Dual-Stage Process: For greater stability, dual-stage models reduce pressure in two phases. The first stage drops inlet pressure to an intermediate level (e.g., 100-200 psig), and the second fine-tunes it to the desired outlet (e.g., 0-50 psig). This minimizes “droop” (pressure drop under high flow) and handles cylinder pressure variations as gas depletes.

- Flow Control: Integrated flowmeters (in some models) measure output in CFH or LPM, allowing precise adjustment for applications like welding (typically 10-30 CFH for TIG).

- Safety Relief: If outlet pressure builds excessively, a self-relieving mechanism vents gas safely, protecting the system.

This process maintains constant pressure through equilibrium between spring force, diaphragm pressure, and gas flow, ensuring consistent performance.

Types of High-Pressure Argon Gas Regulators

Regulators vary by design and application:

- Single-Stage: Simple, cost-effective for general use; reduces pressure in one step but prone to fluctuations.

- Dual-Stage: Offers superior stability for precision work; ideal for labs or long-duration welding.

- Flowmeter Regulators: Combine regulation with flow measurement; common in TIG welding for accurate shielding gas control.

- Ultra-High-Pressure Models: Like the Harris HP8700, for pressures up to 7500 psig in testing applications.

- Pressure-Only vs. Flow-Control: Some focus on pressure, others on volume flow.

Selection depends on inlet pressure, required output, and gas mix (e.g., argon/helium).

Applications

High-pressure argon regulators are versatile:

- Welding: Essential for TIG/MIG, providing shielding to prevent defects in metals like aluminum.

- Laboratories: Regulate gas for analytical instruments, ensuring purity.

- High-Pressure Testing: Pressurize systems in aerospace, hydraulics, and automotive for safety checks.

- Manufacturing: Used in metal 3D printing and purging operations.

Selection and Setup

Choose based on gas type, pressure range, flow needs, and certifications (e.g., CGA E-4). For setup: Clean the cylinder valve, attach securely, open slowly, and check for leaks with soapy water.

Safety Considerations

Always match regulator to gas; never use oil on fittings. Monitor gauges, avoid over-tightening, and use in well-ventilated areas. Self-relieving features prevent bursts. Regular leak checks and proper storage are crucial.

Maintenance and Troubleshooting

Inspect for wear, clean filters, and replace diaphragms periodically. Troubleshoot issues like creeping pressure (worn seat) or leaks (faulty seals) by consulting manuals. Store dry and upright.

Conclusion

A high-pressure argon gas regulator is a vital tool for safe and efficient gas management, blending engineering precision with practical utility. Understanding its components and operation empowers users to optimize performance across applications. As technology advances, these devices continue to evolve, ensuring reliability in an inert gas-dependent world.

For more about what is a high pressure argon gas regulator, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

771L Male Run Tee | Stainless Steel High Quality High Purity Male Run Tee Branch Tee Pipe Fittings

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

JR1000 Series UHP Ultra High Purity Single Stage Pressure Reducing Regulator And Low To Intermediate Flow

-

High Purity Chemical Dispense System & Packing System For Semiconductors JW-200L-CDM & JW-1000L-CDM

-

739LF High Purity Female Adapter Tube To Pipe Fittings And Connectors

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions