Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What is a Specialty Gas Pressure Reducing Valve Used For?

- Pressure Regulator Valve Manufacturer

- 1 1 4 pressure reducing valve, 1 2 pressure reducing valve, 1 pressure reducing valve, 2 pressure reducing valve, adjusting pressure reducing valve, cylinder pressure reducing valve, Gas Pressure Reducing Valve, high pressure reducing valve, low pressure reducing valve, Medical Oxygen Regulatorpressure reducing valve manufacturers in india, natural gas pressure reducing valve, nitrogen pressure reducing valve, Pressure Reducing Valve, pressure reducing valve adjustment, Pressure Reducing Valve China, pressure reducing valve for nitrogen gas, pressure reducing valve malaysia, Pressure Reducing Valve Manufacturer, pressure reducing valve manufacturers, pressure reducing valve manufacturers and supplier in china, pressure reducing valve manufacturers in ahmedabad, pressure reducing valve manufacturers in india, pressure reducing valve supplier in philippines, pressure reducing valve suppliers, pressure reducing valve suppliers in qatar, pressure reducing valve suppliers in south africa, pressure reducing valve suppliers in uae, Stainless Steel Pressure Reducing Valve, what is a pressure reducing valve

- No Comments

What is a Specialty Gas Pressure Reducing Valve Used For?

In the world of industrial, scientific, and medical applications, gases play a pivotal role in enabling processes that range from chemical analysis to life-saving medical treatments. Specialty gases, which include high-purity, rare, corrosive, or toxic gases, are essential in these fields. However, handling these gases safely and effectively requires precise control over their pressure and flow. This is where the specialty gas pressure reducing valve (PRV), also commonly referred to as a pressure regulator, comes into play.

A specialty gas pressure reducing valve is a specialized device designed to reduce the high pressure of gas stored in cylinders or pipelines to a lower, more manageable level suitable for downstream equipment and processes. Unlike general-purpose valves, these are engineered to meet the stringent demands of specialty gases, ensuring purity, safety, and reliability. They prevent over-pressurization, maintain consistent delivery pressure, and protect sensitive systems from damage.

The primary use of a specialty gas PRV is to facilitate the safe and controlled release of gases in applications where even minor fluctuations in pressure could compromise results or pose hazards. For instance, in laboratories, these valves ensure that analytical instruments receive a steady supply of calibration gases. In the semiconductor industry, they handle ultra-high-purity gases critical for manufacturing processes. Medical facilities rely on them for oxygen and other therapeutic gases, while industrial settings use them for welding or chemical reactions involving reactive gases.

This article delves into the intricacies of specialty gas pressure reducing valves, exploring their design, functionality, types, applications, and best practices for selection, installation, and maintenance. By understanding these components, users can appreciate their indispensable role in modern technology and industry. With advancements in materials and engineering, these valves continue to evolve, supporting increasingly sophisticated applications.

Understanding Pressure Reducing Valves

Pressure reducing valves, in general, are mechanical devices that automatically adjust the pressure of a fluid— in this case, gas— from a higher inlet pressure to a lower outlet pressure. They are integral to fluid control systems, ensuring that downstream components operate within safe pressure limits. The basic principle involves balancing forces to maintain a set outlet pressure despite variations in inlet pressure or flow demand.

In the context of gases, pressure reducing valves differ from those used for liquids due to the compressible nature of gases, which can lead to more significant pressure drops and flow variations. A typical PRV consists of three main elements: a loading mechanism, a sensing element, and a control element. The loading mechanism, often a spring, sets the desired outlet pressure. The sensing element, usually a diaphragm, detects changes in outlet pressure. The control element, a valve seat and poppet, modulates the flow to achieve pressure reduction.

For specialty gases, these valves must go beyond basic functionality. Specialty gases are defined as gases prepared to specific purity levels or compositions, often exceeding 99.999% purity, and include mixtures like calibration standards, zero gases, or reactive compounds such as ammonia, chlorine, or silane. These gases are used in environments where contamination could ruin experiments or products, or where leaks could be hazardous.

The need for specialty gas PRVs arises from the high storage pressures in cylinders, which can reach up to 3000 psig or more. Directly connecting equipment to such high pressures would risk damage or unsafe operation. Thus, the PRV steps down this pressure to typically 0-500 psig, depending on the application. Moreover, they incorporate features like metal diaphragms to prevent gas permeation and ensure purity.

Historically, pressure regulators have been used since the early 20th century in industrial gas handling, but specialty versions emerged with the growth of analytical chemistry and electronics in the mid-20th century. Today, they are manufactured to comply with standards like those from the Compressed Gas Association (CGA), ensuring compatibility and safety.

Specialty Gases and Their Unique Requirements

Specialty gases encompass a broad category beyond common industrial gases like oxygen or nitrogen. They include high-purity versions of inert gases (e.g., helium, argon), reactive gases (e.g., hydrogen sulfide, carbon monoxide), and custom mixtures tailored for specific uses. These gases are critical in sectors such as pharmaceuticals, environmental monitoring, food processing, and aerospace.

The unique requirements for handling specialty gases stem from their properties. High-purity gases must remain uncontaminated to avoid interfering with processes like gas chromatography or laser operations. Corrosive gases, such as hydrogen chloride, can degrade standard materials, necessitating valves made from resistant alloys like Hastelloy or Monel. Toxic or flammable gases demand leak-proof designs to prevent health risks or explosions.

Pressure reducing valves for these gases must address these challenges. For example, they often feature electropolished surfaces to minimize particle generation and adsorption sites. Seals and seats are made from materials like PTFE or Viton to withstand chemical attack while maintaining a tight seal. In ultra-high-purity applications, such as semiconductor fabrication, regulators use vacuum-compatible designs to prevent outgassing.

Furthermore, specialty gases are often supplied in cylinders with specific valve outlets standardized by CGA connections. The PRV must match these to ensure a secure fit. For liquefied gases like carbon dioxide or nitrous oxide, regulators may include heated elements to prevent freezing during expansion.

The role of PRVs in this context is not just pressure reduction but also system protection. They incorporate relief valves to vent excess pressure, preventing ruptures. In high-flow applications, they maintain stability to avoid surges that could disrupt processes.

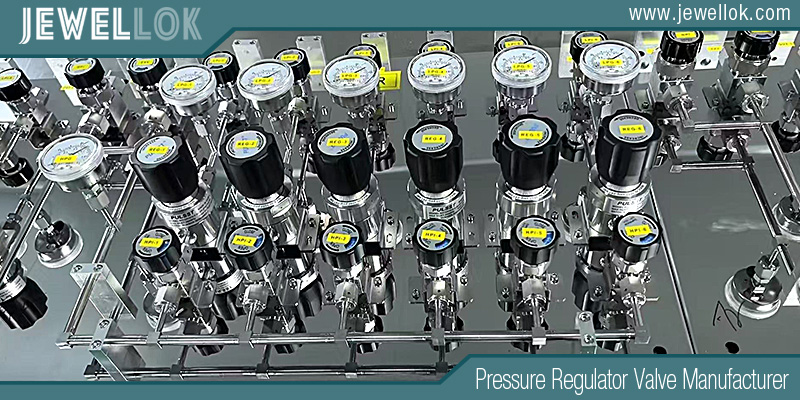

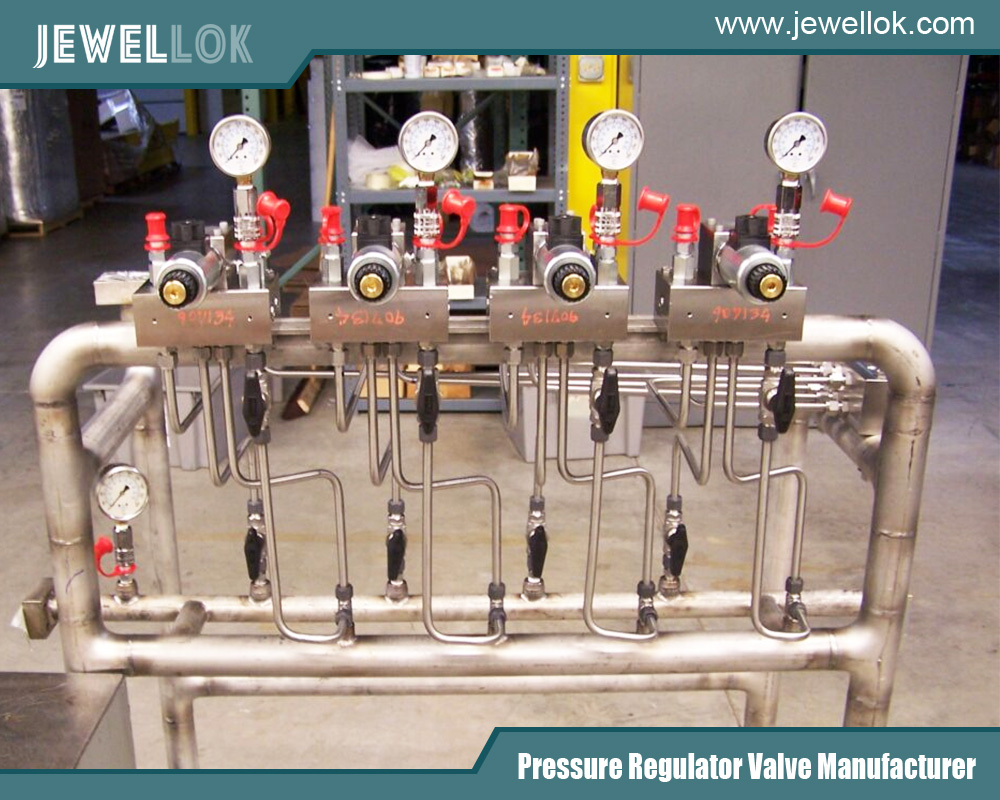

Design and Components of Specialty Gas PRVs

The design of a specialty gas pressure reducing valve is a marvel of precision engineering, tailored to handle the demands of sensitive gas applications. At its core, the valve body is typically constructed from brass, stainless steel, or exotic alloys to ensure compatibility with the gas and resistance to corrosion.

Key components include:

– Inlet and Outlet Ports: The inlet connects to the high-pressure source via a CGA fitting, while the outlet leads to the downstream system. These ports are designed for minimal dead volume to reduce contamination risks.

– Pressure Gauges: Dual gauges monitor inlet and outlet pressures. High-purity models use bourdon tube gauges with isolated wetted parts.

– Adjusting Mechanism: A hand knob or screw compresses the loading spring to set the outlet pressure. In automated systems, this may be pneumatic or electronic.

– Diaphragm: The sensing element, often made of stainless steel or Hastelloy, flexes in response to pressure changes, isolating the gas from the spring chamber to prevent contamination.

– Valve Seat and Poppet: The control element, where the poppet moves against the seat to regulate flow. Soft seats like Kel-F are used for tight shutoff in low-pressure applications.

– Relief Valve: An integrated safety feature that opens at a preset pressure to protect the system.

– Filters and Purge Ports: Some models include inlet filters to trap particles and purge valves for evacuating air or residual gases during startup.

Technical details vary by model. For instance, delivery pressure ranges can be from vacuum to 6000 psig, with flow capacities up to several hundred standard cubic feet per minute (SCFM). Helium leak rates are often specified at 10^-9 cc/sec for high-integrity designs.

In two-stage regulators, an intermediate chamber reduces pressure in steps, enhancing stability. Piston-sensed designs are used for high-pressure applications where diaphragms might fail.

How Specialty Gas PRVs Work

The operation of a specialty gas PRV relies on a balance of forces. When the valve is closed, the outlet pressure is zero. Turning the adjusting knob compresses the loading spring, which pushes on the diaphragm. This force displaces the poppet from the seat, allowing gas to flow from the high-pressure inlet to the outlet.

As outlet pressure builds, it acts against the diaphragm, opposing the spring force. When these forces equilibrate, the poppet stabilizes, maintaining the set pressure. If demand increases (e.g., more flow), outlet pressure drops slightly, causing the diaphragm to open the valve further. Conversely, reduced demand closes it.

In single-stage PRVs, as cylinder pressure decreases, outlet pressure rises slightly due to the “supply pressure effect,” requiring adjustments. Two-stage models mitigate this by first reducing to a fixed intermediate pressure, then fine-tuning in the second stage.

For specialty applications, features like compensated seats minimize droop (pressure drop with increased flow). Electronic regulators use sensors and actuators for precise control, integrating with PLC systems.

Types of Specialty Gas PRVs

Specialty gas PRVs are categorized by design, application, and features:

– Single-Stage Regulators: Simple, cost-effective for applications tolerant of pressure variations. Ideal for short-duration uses or low inlet pressures (<1000 psig).

– Two-Stage Regulators: Provide stable output for high inlet pressures or precise needs. Common in analytical labs.

– High-Purity Regulators: Feature bar stock bodies, metal diaphragms, and electropolished finishes for minimal contamination. Used in semiconductors and pharma.

– Corrosion-Resistant Regulators: Made from materials like PVC or Teflon-lined for aggressive gases.

– Ultra-High-Pressure Regulators: Handle pressures up to 10,000 psig for specialized testing.

– Line Regulators: Point-of-use devices for pipeline systems, often with low inlet limits.

– Back-Pressure Regulators: Maintain upstream pressure, useful in venting or recirculation.

Each type addresses specific needs, with hybrids available for custom setups.

Applications Across Industries

Specialty gas PRVs find extensive use in diverse sectors:

– Laboratory and Analytical: In gas chromatography, mass spectrometry, and calibration, they deliver precise pressures for carrier gases like helium.

– Semiconductor Manufacturing: Ultra-high-purity regulators handle dopants like arsine, ensuring contamination-free deposition.

– Medical and Healthcare: For oxygen therapy, anesthesia, and respiratory equipment, medical-grade PRVs comply with ISO standards.

– Environmental Monitoring: Regulate gases for air quality analyzers and emission testing.

– Industrial Processes: In welding with argon mixtures or chemical synthesis with reactive gases.

– Aerospace and Defense: For propulsion testing with high-pressure gases.

– Food and Beverage: Control CO2 for carbonation or nitrogen for packaging.

These applications highlight the valve’s versatility in enabling safe, efficient gas use.

Selection Criteria

Choosing the right specialty gas PRV involves evaluating:

– Gas Compatibility: Material resistance to corrosion or reaction.

– Pressure Ranges: Inlet max, outlet set point, and flow capacity.

– Purity Requirements: High-purity designs for sensitive apps.

– Environmental Factors: Temperature, vibration, and installation space.

– Safety Features: Relief valves, gauges, and certifications.

– Cost and Maintenance: Balance upfront cost with longevity.

Consulting manufacturers’ specs ensures optimal selection.

Installation, Operation, and Maintenance

Installation requires clean connections, proper torque, and leak testing. Operation involves slow pressurization, adjusting to set pressure, and monitoring gauges.

Maintenance includes periodic inspections for leaks, diaphragm wear, and cleaning with approved solvents. Avoid lubrication and store in clean environments.

Safety Considerations

Safety is paramount: Use only for intended gases, vent properly, and incorporate purge systems. Risks include asphyxiation, toxicity, and fire; mitigation via training and equipment like relief valves.

Conclusion

Specialty gas pressure reducing valves are vital for controlling high-pressure gases in demanding applications, ensuring safety, purity, and performance. Their sophisticated design supports innovation across industries, making them indispensable tools in modern science and engineering.

For more about what is a specialty gas pressure reducing valve used for, you can pay a visit to Jewellok at https://www.jewellok.com/products/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

Tags

Recommended Products

-

Automatic Gas Switchover System Automatic Switchover Manifold Automatic Gas Cylinder Switchover

-

Scrubber Tail Gas Treatment Cabinet Waste Gas Treatment Wet Scrubber Exhaust Gas Treatment Spray Tower

-

Long Gland LG Series For Ultra High Purity Gas And Chemical Delivery Systems

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

772 LF Female Branch Tee | Stainless Steel Tube Fitting Female Branch Tee 1/2 in. Tube OD x 1/2 in. Tube OD x 3/8 in. Female NPT

-

Stainless Steel Mini Elbow Mini Tee Mini Cross Mini Tribow Ultrahigh Purity Mini Butt Weld Fittings

-

High Purity High Pressure Specialty Gas Pressure Regulators Specialty Gases Pipeline Engineering Equipments Manufacturer And Supplier