Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What is an Automatic Gas Switchover System with Line Regulator?

- Pressure Regulator Valve Manufacturer

- 2-stage auto changeover lp propane gas regulator, automatic co2 tank switch, automatic gas cylinder changeover unit, automatic gas switchover manifold system, Automatic gas switchover system, Automatic Non-Electric Gas Cylinder Changeover Systems, automatic switchover manifold, best auto changeover propane regulator, Best Gas Switchover Manifolds for Gas Management, best rv propane automatic changeover regulator, co2 cylinder auto changeover controller, dual propane tank changeover regulator, gas changeover regulator, Gas manifold systems with automatic switch-over, Industrial Automatic Changeover Manifolds, manual propane changeover valve, propane auto changeover valve without regulator, propane automatic changeover regulator, rv propane auto changeover regulator, Specialty Gas Fully Automatic Changeover Manifolds, two-stage rv propane regulator with automatic changeover, utomatic Switchover System with Line Regulator

- No Comments

What is an Automatic Gas Switchover System with Line Regulator?

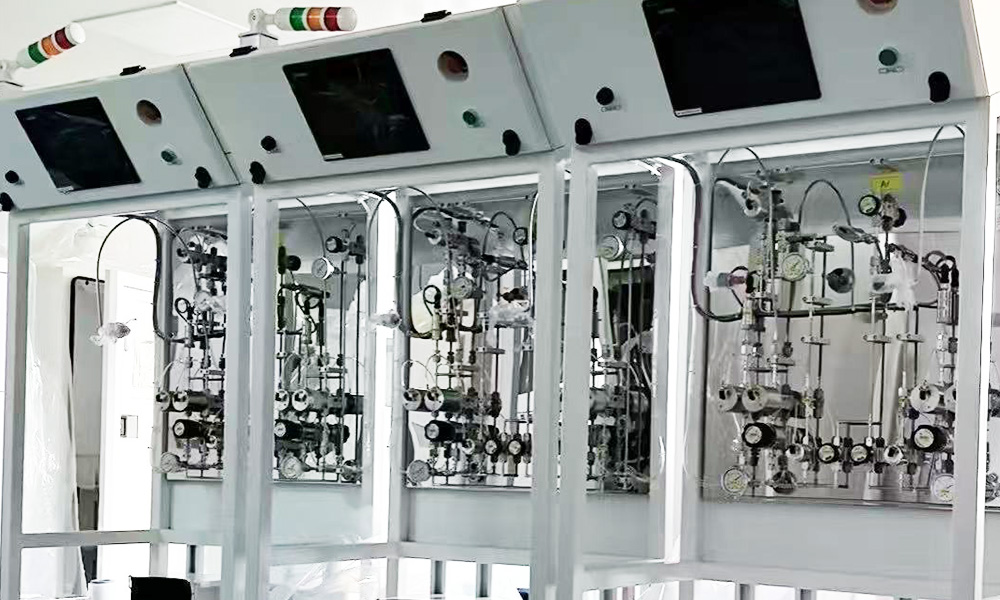

In environments where a reliable and continuous gas supply is critical, an automatic gas switchover system with a line regulator emerges as an indispensable tool. This sophisticated system is designed to seamlessly transition between gas sources while maintaining a consistent pressure, ensuring uninterrupted operation in applications ranging from scientific research to medical care and industrial processes. This article explores the definition, components, operation, applications, benefits, and key considerations of an automatic gas switchover system with a line regulator, providing a comprehensive understanding of its role and significance.

Introduction

Gas is a vital resource in numerous settings, powering experiments in laboratories, sustaining patients in hospitals, and driving processes in factories. However, managing gas supply manually—monitoring cylinder levels and switching to a new source when one runs out—can be inefficient, error-prone, and, in some cases, dangerous. An automatic gas switchover system with a line regulator addresses these challenges by combining two essential functions: it automatically switches from a depleted gas source to a full one and regulates the pressure of the gas delivered to the end-use application.

The automatic switchover feature eliminates the need for constant human oversight, ensuring a continuous flow of gas without interruption. Meanwhile, the line regulator maintains a stable output pressure, compensating for variations in the source pressure to meet the precise requirements of downstream equipment. Together, these components create a reliable and efficient gas supply solution that enhances safety, productivity, and resource management across diverse industries.

This article will break down the system into its core elements, explain how it operates, and highlight its practical applications and advantages. Whether you’re a lab technician, a hospital administrator, or an industrial engineer, understanding this system can help you optimize your gas supply infrastructure.

Components of the System

To grasp how an automatic gas switchover system with a line regulator functions, it’s essential to examine its key components. Each part plays a specific role in ensuring the system delivers gas reliably and at the correct pressure.

Gas Cylinders or Sources

The system begins with the gas sources, typically high-pressure cylinders filled with gases such as oxygen, nitrogen, helium, or specialty mixtures. In some cases, bulk tanks or gas generators may serve as the supply, depending on the scale of the operation. These sources provide the raw material that the system manages and distributes.

Manifold

The manifold is the structural backbone that connects multiple gas cylinders to the system. It consists of valves, fittings, and piping that allow gas from different cylinders to converge into a single outlet. A duplex manifold, for instance, connects two cylinders—one primary and one secondary—while larger systems may accommodate additional cylinders for greater redundancy.

Switchover Mechanism

At the heart of the system lies the switchover mechanism, which automates the transition between gas sources. This component monitors the primary source and, when it detects depletion (typically via pressure sensors or flow meters), closes the valve to the empty cylinder and opens the valve to the backup cylinder. Modern switchover mechanisms may incorporate electronic controls for precision and reliability.

Line Regulator

The line regulator is positioned downstream of the switchover mechanism and controls the pressure of the gas entering the distribution line. It reduces high-pressure gas from the cylinders to a stable, usable level, ensuring consistency despite fluctuations in the source. Single-stage or dual-stage regulators may be used, depending on the precision required.

Pressure Gauges and Indicators

To keep operators informed, pressure gauges and indicators are installed at key points—on the cylinders, manifold, and regulator outlet. These devices provide real-time data on gas pressure, enabling quick assessment of the system’s status and signaling when a cylinder needs replacement.

Alarms and Notifications

Many systems include alarms—audible, visual, or remote—to alert users when a switchover occurs or when gas levels are critically low. These notifications ensure timely intervention, such as replacing an empty cylinder, without disrupting the gas supply.

Safety Devices

Safety is paramount, and safety devices like pressure relief valves protect the system from overpressure conditions. These valves automatically release excess gas if pressure exceeds safe limits, preventing damage or hazards.

Together, these components form a cohesive system that automates gas supply management while prioritizing safety and efficiency.

How It Works

The operation of an automatic gas switchover system with a line regulator is a streamlined process designed for reliability. Here’s a step-by-step explanation:

- Setup: Two or more gas cylinders are connected to the manifold. One is designated as the primary source, with the others as backups.

- Gas Flow: Gas flows from the primary cylinder through the manifold and into the switchover mechanism.

- Monitoring: The switchover mechanism continuously tracks the primary source’s status, often by measuring pressure or flow rate.

- Depletion Detection: When the primary cylinder’s pressure drops below a set threshold, indicating it’s nearly empty, the switchover is triggered.

- Switching: The mechanism closes the valve to the depleted cylinder and opens the valve to the secondary cylinder, maintaining uninterrupted gas flow.

- Pressure Regulation: The gas then passes through the line regulator, which adjusts the pressure to the required level for the application.

- Delivery: The regulated gas is delivered to the point of use via the distribution line.

- Notification: Alarms or indicators alert operators to the switchover, prompting cylinder replacement.

This automated sequence ensures a steady gas supply with minimal human intervention, making it ideal for critical applications.

Applications

Automatic gas switchover systems with line regulators are used across a variety of industries where gas reliability is non-negotiable. Here are some prominent examples:

Laboratories

In scientific labs, instruments like gas chromatographs and mass spectrometers depend on a constant supply of gases such as helium or nitrogen. An interruption can ruin experiments or damage equipment, making automatic switchover systems essential.

Healthcare

Hospitals rely on medical gases—oxygen, nitrous oxide, and medical air—for patient care, anesthesia, and respiratory support. In critical areas like operating rooms, these systems ensure a continuous supply, safeguarding patient safety.

Industrial Manufacturing

Manufacturing processes, such as welding or chemical production, use gases for cutting, shielding, or reactions. Automatic switchover systems prevent downtime, maintaining production efficiency.

Semiconductor Industry

Semiconductor fabrication requires ultra-high purity gases in a controlled environment. These systems ensure uninterrupted delivery, preventing defects in sensitive processes.

Research and Aerospace

Research facilities and aerospace applications use gases for testing and propulsion. The reliability of automatic switchover systems supports mission-critical operations.

From environmental monitoring to food processing, the system’s versatility makes it a cornerstone of modern gas supply management.

Benefits

The advantages of an automatic gas switchover system with a line regulator are numerous, offering both practical and economic value:

– Continuous Supply: Prevents interruptions, critical for applications where downtime is costly or dangerous.

– Reduced Labor: Automation eliminates manual monitoring and switching, saving time and reducing labor costs.

– Safety: Minimizes handling of high-pressure cylinders and includes safety features like relief valves.

– Stable Pressure: Ensures consistent output, vital for equipment performance and product quality.

– Efficient Gas Use: Fully depletes cylinders before switching, reducing waste.

– Remote Capabilities: Advanced systems allow monitoring from afar, enhancing operational control.

– Productivity: Eliminates downtime, boosting overall efficiency.

These benefits collectively enhance operational reliability and justify the system’s adoption in demanding environments.

Considerations

Implementing such a system requires careful planning. Key factors include:

– Gas Compatibility: Components must suit the gas type (e.g., corrosive gases need resistant materials).

– Pressure and Flow: The system must meet the application’s pressure and flow demands.

– Space: Adequate room is needed for installation and maintenance.

– Maintenance: Regular servicing ensures long-term reliability.

– Cost: Initial investment should be weighed against long-term savings.

– Regulations: Compliance with industry standards is essential.

Addressing these ensures the system performs optimally for its intended use.

Conclusion

An automatic gas switchover system with a line regulator is a vital tool for managing gas supply in settings where reliability and precision are paramount. By automating source switching and regulating pressure, it delivers uninterrupted gas at the right level, enhancing safety, efficiency, and productivity. From labs to hospitals to factories, its applications are vast, and its benefits—reduced labor, improved safety, and optimized gas use—make it a smart investment. With careful consideration of compatibility, requirements, and maintenance, this system can significantly elevate gas supply management, meeting the needs of today’s gas-dependent industries.

For more about what is automatic gas switchover system with line regulator, you can pay a visit to Jewellok at https://www.jewellok.com/how-does-a-specialty-gas-fully-automatic-changeover-manifold-system-work/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

7102L Stainless Steel 316L SS Union Cross Ultra High Purity Long Arm Union Elbow Tee Cross Butt Weld Fittings

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve

-

High Purity High Pressure Gas Cylinder Pressure Regulators Pressure Reducing Valve JSR-1E Series

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

Pressure Control Panels For High Purity Gas Control System JSP-3AE Series From Pressure Control Panels Suppliers And Manufacturer

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

Ultra High Purity Stainless Steel Compressed Gas Changeover Manifold Panel System For Integrated Gas Supply System