Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What Is An Integrated Gas Supply System?

- Pressure Regulator Valve Manufacturer

- fully integrated gas supply system, Integrated Central Medical Gas Supply System, integrated fuel system module, integrated fuel systems, Integrated Gas holder Manufacturing Factory, Integrated Gas Management System, integrated gas supply system, integrated gas system, Integrated Gas System (IGS), Integrated Gas System China, integrated gas system china supplier, Integrated Gas System in Semiconductor, Integrated Gas System in the Semiconductor Companies, integrated gas system manufacturer, integrated gas system manufacturer China, integrated gas system manufacturer in china, integrated gas system manufacturer in india, integrated gas system supplier, Integrated Gas Systems in the Semiconductor, Integrated Management System

- No Comments

What Is An Integrated Gas Supply System?

In today’s rapidly evolving energy landscape, the demand for efficient, reliable, and sustainable gas supply systems has never been more critical. An integrated gas supply system represents a holistic and strategic approach to managing the entire gas supply chain—from production to consumption. By seamlessly coordinating gas sources, storage facilities, distribution networks, and end-users, these systems ensure that gas is delivered efficiently to meet the diverse needs of industries, power plants, and households. This article explores the key components, integration aspects, benefits, challenges, real-world examples, and future trends of integrated gas supply systems, shedding light on their growing importance in the global energy mix.

Components of an Integrated Gas Supply System

An integrated gas supply system is built upon four fundamental components, each playing a vital role in ensuring the smooth flow of gas from its origin to its final use. Below, we delve into each component in detail.

a. Gas Sources

Gas sources are the foundation of any supply system, determining the type, availability, and environmental impact of the gas being supplied. These sources include:

Natural Gas: Extracted from underground reservoirs, natural gas is the most widely used gas source due to its abundance and relatively low carbon footprint compared to other fossil fuels. It is typically composed of methane and is sourced from fields both onshore and offshore.

Biogas: Produced through the anaerobic digestion of organic waste—such as agricultural residues, food waste, or sewage—biogas is a renewable alternative. It consists primarily of methane and carbon dioxide and offers a sustainable option for gas supply.

Synthetic Gas: Generated through chemical processes like coal gasification or renewable hydrogen production, synthetic gas provides flexibility in regions lacking natural gas reserves. Hydrogen, in particular, is gaining attention as a clean energy carrier.

The choice of gas source depends on factors such as regional availability, economic feasibility, and environmental goals, making it a critical decision in designing an integrated system.

b. Storage Facilities

Storage is essential for balancing supply and demand, especially given the seasonal and daily fluctuations in gas consumption. Common storage options include:

Underground Storage: Depleted gas fields, salt caverns, or aquifers are repurposed to store large volumes of gas. These facilities are cost-effective for long-term storage and are widely used in regions with extensive gas infrastructure.

Liquefied Natural Gas (LNG) Tanks: Gas is cooled to a liquid state (-162°C) for storage in insulated tanks, reducing its volume by 600 times. LNG is ideal for regions without pipeline access or for international trade.

Compressed Natural Gas (CNG) Cylinders: Gas is stored under high pressure in cylinders, suitable for smaller-scale or mobile applications, such as vehicle fuel.

Each storage method has unique advantages—capacity for underground storage, portability for LNG, and flexibility for CNG—allowing systems to tailor solutions to specific needs.

c. Distribution Networks

The distribution network is the backbone of the gas supply system, ensuring gas reaches its destination efficiently and reliably. Key methods include:

Pipelines: The most common and economical method for transporting large volumes of gas over land. Pipeline networks can span thousands of kilometers, connecting gas fields to urban centers and industrial hubs.

Tankers: Used primarily for LNG, tankers transport gas across oceans or to remote locations inaccessible by pipelines. This method supports global gas trade and regional supply flexibility.

Other Methods: In areas lacking pipeline infrastructure, gas can be transported via trucks or rail in the form of CNG or small-scale LNG, providing last-mile connectivity.

A robust distribution network minimizes delays, reduces losses, and ensures gas is available where and when it’s needed.

d. End-Users

The end-users of gas are diverse, spanning multiple sectors with varying demands:

Power Plants: Gas-fired power plants use natural gas or other gases to generate electricity, offering a cleaner alternative to coal.

Industries: Manufacturing sectors rely on gas for heating, as a feedstock (e.g., in fertilizer production), or for process energy in steelmaking and refining.

Households: Millions of homes worldwide use gas for cooking, heating, and hot water, making it a staple of domestic energy consumption.

Understanding these users’ consumption patterns—such as peak winter demand for heating or steady industrial use—is key to optimizing the system.

Integration Aspects

The hallmark of an integrated gas supply system is its ability to connect and optimize these components through advanced technology, streamlined operations, and regulatory alignment.

a. Technological Integration

Modern systems leverage cutting-edge technologies to enhance efficiency, safety, and responsiveness:

Internet of Things (IoT): Smart sensors monitor gas flow, pressure, and quality in real-time, enabling proactive maintenance and leak detection.

Artificial Intelligence (AI): AI algorithms analyze data to predict demand, optimize supply routes, and improve energy efficiency, reducing operational costs.

Blockchain: This technology ensures transparency in gas transactions and supply chain tracking, particularly in complex, multi-party systems.

These tools create a “smart” gas network capable of adapting to disruptions and improving overall performance.

b. Operational Integration

Operational efficiency is achieved by coordinating the supply chain’s moving parts:

Production Schedules: Gas extraction or production is timed to match storage capacity and demand forecasts.

Storage Management: Facilities are filled during low-demand periods and tapped during peaks, smoothing out supply fluctuations.

Distribution Logistics: Routes and transport modes are optimized to minimize costs and delivery times.

This seamless coordination reduces waste, prevents bottlenecks, and ensures a steady gas flow.

c. Regulatory and Policy Integration

Gas supply systems operate within a web of regulations that ensure safety, environmental protection, and fair market practices:

Safety Standards: Strict guidelines govern gas handling, storage, and transport to protect workers and communities.

Environmental Regulations: Rules mandate emissions reductions, leak prevention, and the adoption of cleaner gas sources.

Market Policies: Pricing, competition, and cross-border trade are regulated, especially in integrated systems spanning multiple jurisdictions.

Compliance with these frameworks is essential for system legitimacy and public trust.

Benefits of Integrated Gas Supply Systems

Integrated systems offer a range of advantages that address modern energy challenges:

a. Reliability and Security

By diversifying gas sources and maintaining robust storage and distribution networks, these systems can withstand supply disruptions—whether due to geopolitical tensions, natural disasters, or technical failures. For instance, if a pipeline is damaged, stored LNG or alternative sources can fill the gap.

b. Cost Efficiency

Integration optimizes resource use, reduces operational inefficiencies, and minimizes gas losses (e.g., through leaks). These savings lower the cost of gas for consumers and allow reinvestment in infrastructure upgrades.

c. Environmental Impact

Efficient systems reduce greenhouse gas emissions by optimizing combustion and incorporating renewable gases like biogas or hydrogen. Leak detection technologies further minimize methane—a potent greenhouse gas—escaping into the atmosphere.

d. Flexibility and Scalability

Integrated systems can adapt to shifting demand patterns, such as increased industrial use or seasonal heating needs. They also allow for the integration of new technologies or gas sources, ensuring long-term relevance.

Challenges and Solutions

Despite their benefits, integrated gas supply systems face significant hurdles. Below are the primary challenges and potential solutions:

a. Technical Challenges

Integrating diverse technologies—such as IoT devices with legacy pipelines—can be complex and prone to compatibility issues.

Solution: Standardized protocols and interoperable systems can simplify integration, ensuring all components work together seamlessly.

b. Economic Challenges

The high upfront costs of building or upgrading integrated systems can deter investment, particularly in developing regions.

Solution: Government incentives, public-private partnerships, and a focus on long-term savings can offset initial expenses.

c. Regulatory Challenges

Cross-border systems must navigate differing safety, environmental, and market regulations, complicating operations.

Solution: Harmonizing regulations across regions and adopting flexible compliance strategies can streamline processes.

Case Studies and Examples

Real-world examples illustrate the power of integrated gas supply systems:

Europe’s Gas Network

The European Union has developed one of the world’s most advanced integrated gas networks, connecting multiple countries via pipelines and LNG terminals. This system ensures energy security by allowing gas to flow from diverse sources—such as Russia, Norway, and North Africa—to meet demand across the continent. It has proven resilient during supply disruptions, such as the 2022 Russia-Ukraine conflict, by leveraging stored gas and alternative imports.

Singapore’s LNG Hub

Singapore has emerged as a key LNG trading hub in Asia, integrating LNG storage, regasification, and distribution to serve domestic needs and regional markets. This system enhances energy resilience and positions Singapore as a leader in the global gas trade, demonstrating the economic benefits of integration.

These cases highlight the importance of strategic planning, technological innovation, and regulatory cooperation.

Future Trends

The evolution of integrated gas supply systems will be shaped by several trends:

a. Emerging Technologies

Hydrogen: Green hydrogen, produced using renewable energy, could become a cornerstone of future gas systems, offering a carbon-free fuel.

Carbon Capture and Storage (CCS): CCS technologies can reduce emissions from natural gas, aligning with decarbonization goals.

Digitalization: Advances in AI and IoT will further enhance system efficiency and responsiveness.

b. Market Trends

The shift towards renewable gases—biomethane, hydrogen, and synthetic methane—is accelerating. Meanwhile, decentralized gas networks, such as small-scale LNG or biogas plants, are gaining traction in remote or off-grid areas.

c. Policy Directions

Governments are prioritizing decarbonization and energy security through policies that promote low-carbon gases, emissions reductions, and infrastructure investment. International agreements, like the Paris Accord, will further drive this transition.

Conclusion

Integrated gas supply systems are a cornerstone of modern energy management, offering a comprehensive solution to the challenges of reliability, cost, and sustainability. By connecting gas sources, storage, distribution, and end-users through advanced technologies and strategic coordination, these systems ensure gas remains a vital part of the global energy mix. Despite technical, economic, and regulatory challenges, solutions exist to unlock their full potential. As the world moves towards cleaner energy, integrated systems will play a pivotal role in balancing energy security with environmental responsibility. The future of gas supply lies in integration, innovation, and adaptation—ensuring that gas continues to power industries, homes, and economies in a sustainable way.

For more about what is an integrated gas supply system, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-cabinet/ for more info.

Recent Posts

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

How Does a 316 Stainless Steel Pipe Fitting Work?

A Comprehensive Guide to 316L VIM VAR UHP Gas Regulator

Tags

Recommended Products

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

High Purity High Pressure Gas Cylinder Pressure Regulators Pressure Reducing Valve JSR-1E Series

-

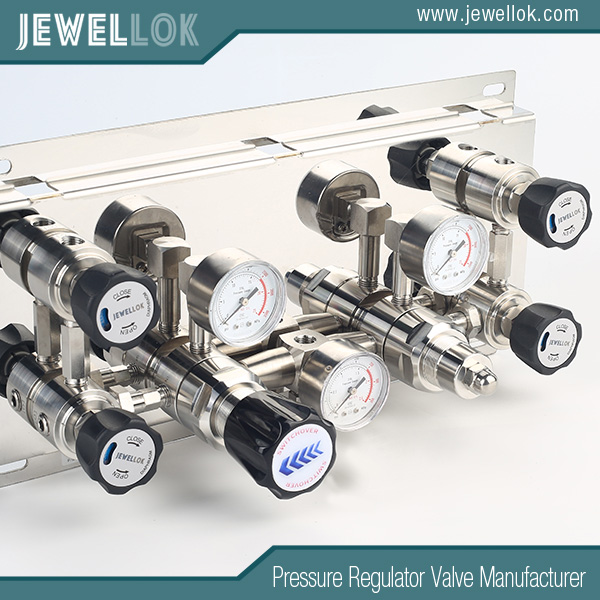

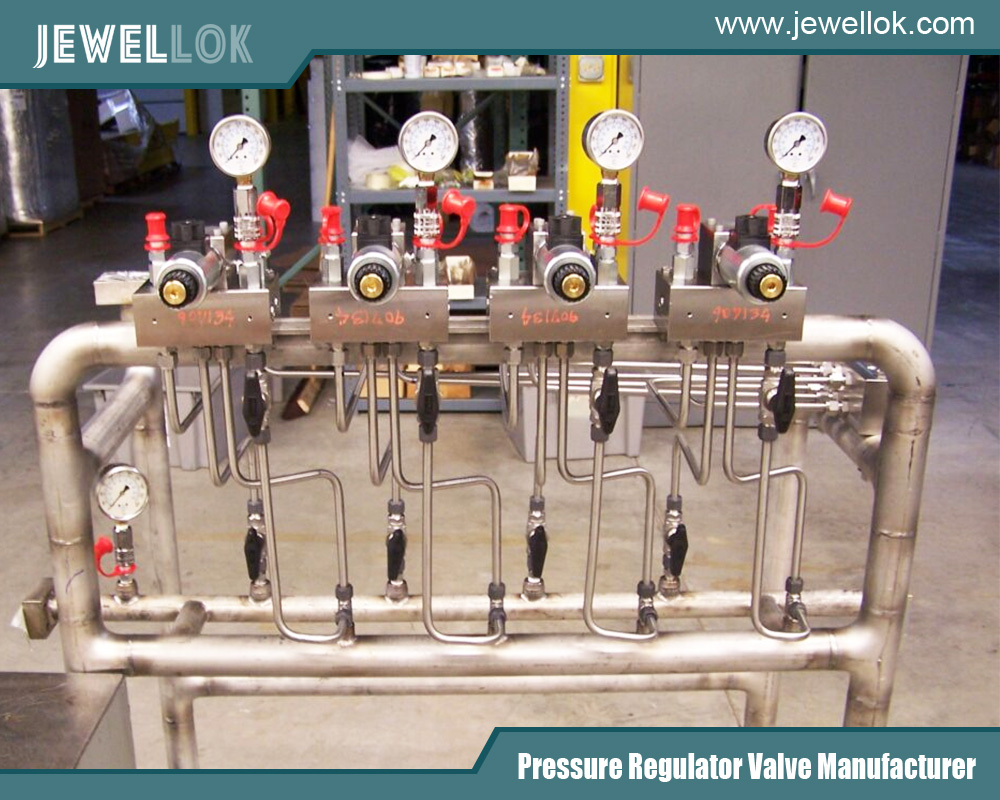

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

High Purity High Pressure 316 Stainless Steel Ball Valves JBV1 Series From High Pressure Ball Valve Manufacturer And Supplier In China

-

Specialty Gas Valves Ultra High Purity Gas Valves Ultra High Purity Gas Cylinder Valves UHP Cylinder Valve Ultra High Purity Gas Regulator

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators