Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What is Exhaust Gas Cleaning System?

- Pressure Regulator Valve Manufacturer

- closed loop scrubber, EGCS, EGCS advantages disadvantages, exhaust gas cleaning system, Exhaust Gas Cleaning system MARPOL, exhaust gas cleaning system scrubber, Exhaust Gas Cleaning Systems, exhaust gas scrubber components, hybrid EGCS, IMO 2020 regulations, marine scrubbers, maritime emissions control, open loop scrubber, scrubber installation costs, scrubber technology ships, ship exhaust cleaning, SOx reduction ships, sulfur oxides removal, washwater treatment marine, Wet Scrubbing Process

- No Comments

What is Exhaust Gas Cleaning System?

In the maritime industry, environmental regulations have become increasingly stringent to combat air pollution from ships. One of the key technologies addressing this challenge is the Exhaust Gas Cleaning System (EGCS), commonly known as a scrubber. An EGCS is a pollution control device installed on marine vessels to remove harmful substances, primarily sulfur oxides (SOx), from engine exhaust gases. This system enables ships to comply with international emission standards while continuing to use cost-effective fuels. As global shipping contributes significantly to atmospheric pollution, understanding EGCS is crucial for engineers, ship operators, and environmental scientists alike.

The primary driver for EGCS adoption stems from regulations set by the International Maritime Organization (IMO). Prior to 2020, ships could burn fuel with up to 3.5% sulfur content, leading to high SOx emissions that contribute to acid rain, respiratory issues, and environmental degradation. The IMO’s MARPOL Annex VI introduced a global sulfur cap of 0.5% effective from January 1, 2020, known as IMO 2020. In designated Emission Control Areas (ECAs), such as parts of North America and Europe, the limit is even stricter at 0.1%. Ships have three main compliance options: switch to low-sulfur fuels, use alternative fuels like liquefied natural gas (LNG), or install an EGCS to “clean” exhaust from high-sulfur fuel oil (HSFO). EGCS offers a practical solution for vessels with high fuel consumption, such as container ships and tankers, by allowing continued use of cheaper HSFO.

How Exhaust Gas Cleaning Systems Work

At its core, an EGCS operates on the principle of wet scrubbing, a process borrowed from industrial air pollution control. The system captures exhaust gases from the ship’s engines or boilers and passes them through a scrubbing tower, where pollutants are absorbed or neutralized.

The process begins with exhaust gas entering the scrubber unit, typically located in the funnel or stack of the ship. Inside the tower, the gas is exposed to a scrubbing medium—usually water sprayed in fine droplets. Sulfur dioxide (SO2), the main component of SOx, is highly soluble in water and reacts to form sulfurous acid (H2SO3), which further oxidizes into sulfuric acid (H2SO4). To neutralize this acidity, alkaline substances are added. In seawater-based systems, the natural alkalinity of seawater (from bicarbonates) reacts with the acid to form harmless compounds like calcium sulfate.

Particulate matter (PM), including soot and heavy metals, is also captured as the gas bubbles through the liquid or collides with droplets. The cleaned exhaust, now with SOx reduced by up to 98%, is released into the atmosphere. The used scrubbing water, or washwater, undergoes treatment to remove contaminants before discharge or recycling, depending on the system type.

Key components of an EGCS include:

– Scrubber Tower: A vertical or horizontal vessel where gas-liquid contact occurs. It may use packing materials or venturi nozzles to enhance mixing.

– Pumps and Nozzles: For circulating and spraying the scrubbing liquid at high pressure.

– Monitoring and Control Systems: Sensors measure pH, turbidity, polycyclic aromatic hydrocarbons (PAHs), and nitrate levels in washwater to ensure compliance with IMO guidelines (MEPC.259(68)).

– Washwater Treatment Unit: Includes separators, filters, and chemical dosing systems to handle sludge and effluents.

Operationally, EGCS integrates with the ship’s engine management system. Exhaust bypass valves allow the system to be deactivated in ports with restrictions. Maintenance involves regular cleaning to prevent scaling from sulfate deposits.

Types of Exhaust Gas Cleaning Systems

EGCS designs vary based on water usage and discharge methods, leading to three main types: open-loop, closed-loop, and hybrid.

Open-loop systems are the simplest and most common. They draw seawater directly from the ocean, use it for scrubbing, and discharge the treated washwater back into the sea. The seawater’s natural buffering capacity neutralizes acids without additional chemicals. These systems are cost-effective in open waters but face criticism for potentially polluting marine environments with acidic, metal-laden water. IMO regulations limit discharge pH to above 6.5 and restrict PAHs and turbidity.

Closed-loop systems recirculate a freshwater or treated water solution mixed with caustic soda (NaOH) or other alkalis. Exhaust gases are scrubbed in a closed circuit, with minimal discharge—only a small bleed-off of concentrated effluent, which is stored onboard or treated ashore. This type is ideal for ECAs or ports banning open discharges, as it minimizes environmental impact. However, it requires chemical storage, higher energy for recirculation, and periodic sludge disposal.

Hybrid systems combine both approaches, allowing operators to switch modes based on location. In open seas, they function as open-loop for efficiency; in restricted areas, they shift to closed-loop. Hybrids offer flexibility but are more complex and expensive to install.

Selection depends on vessel route, fuel type, and local regulations. For instance, cruise ships operating in sensitive coastal areas often prefer hybrids.

Advantages of Exhaust Gas Cleaning Systems

EGCS provides several technical and economic benefits. Environmentally, it drastically cuts SOx emissions, improving air quality near ports and shipping lanes. Studies show reductions in PM and black carbon, indirectly benefiting climate goals. For ship owners, the primary advantage is fuel cost savings—HSFO is typically 20-30% cheaper than low-sulfur alternatives. Payback periods for installation can be as short as 2-5 years for high-consumption vessels.

From an engineering perspective, EGCS enhances operational flexibility. It avoids engine modifications required for some alternative fuels and can integrate with selective catalytic reduction (SCR) for NOx control. Modern systems achieve over 90% efficiency, with some models handling multiple engines simultaneously.

Disadvantages and Challenges

Despite advantages, EGCS is not without drawbacks. Installation costs range from $2-10 million per vessel, depending on size and type, involving retrofits that may require dry-docking. Space constraints on older ships pose challenges, as scrubbers add weight and alter stability.

Operationally, systems consume 1-2% extra fuel for pumps and fans, slightly increasing CO2 emissions—a trade-off in the push for decarbonization. Maintenance is critical; corrosion from acidic environments demands materials like high-grade stainless steel or coatings. Washwater treatment adds complexity, with risks of non-compliance fines if monitoring fails.

Environmental concerns are prominent. Open-loop discharges can acidify surface waters and introduce toxins, prompting bans in ports like Singapore, California, and parts of Europe. Closed-loop systems mitigate this but generate hazardous sludge requiring port disposal facilities. Critics argue EGCS merely shifts pollution from air to sea, delaying the transition to cleaner fuels.

Future Trends and Conclusion

The EGCS market is evolving rapidly. As of 2025, over 5,000 vessels have installed scrubbers, with growth driven by fuel price differentials. Innovations include dry scrubbers using lime pellets for SOx absorption, though less common in marine applications. Integration with carbon capture and ammonia fuel systems is on the horizon, aligning with IMO’s 2050 net-zero goals.

Regulatory pressures are intensifying. The IMO is reviewing washwater guidelines, potentially mandating stricter treatment. Ports may expand no-discharge zones, favoring closed-loop or zero-emission alternatives.

In conclusion, the Exhaust Gas Cleaning System represents a vital bridge technology in maritime decarbonization. By enabling compliance with sulfur regulations, it balances economic viability with environmental protection. However, its long-term role depends on addressing discharge impacts and complementing broader shifts to sustainable shipping. As the industry navigates these waters, EGCS underscores the intersection of engineering ingenuity and regulatory necessity.

For more about what is exhaust gas cleaning system, you can pay a visit to Jewellok at https://www.specialtygasregulator.com/product-category/specialty-gas-cabinet/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

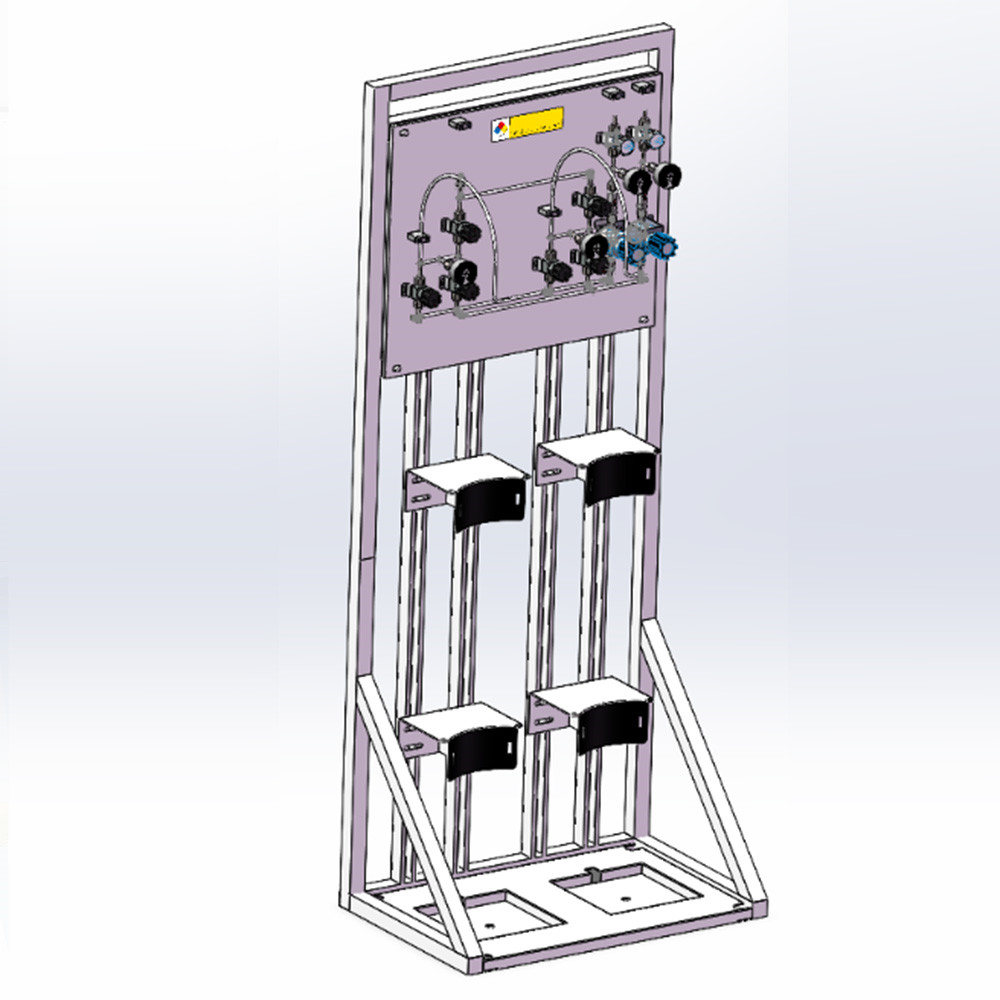

High Purity Semi-Auto Stainless Steel Changeover Manifold System, Nitrogen High Pressure Control Panel With Semiconductor Valve Manifold Box Diaphragm Valves

-

772L Male Branch Tee | Stainless Steel High-Purity Tube Fitting Male Branch Tee

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters