Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What Is Fully Automatic Specialty Gas Cabinets With Gas Panel For NF3 Gas

- Pressure Regulator Valve Manufacturer

- automatic gas cabinets with gas panel, Automatic Special Gas Cabinet, best specialty gas cabinet companies in india, best specialty gas cabinet companies in taiwan, best top 10 specialty gas cabinet companies in taiwan, fully automatic gas cabinets with gas panel, fully automatic gas cabinets with gas panel for nf3 gas, fully automatic specialty gas cabinets with gas panel for nf3 gas, Gas Cabinet for Flammable Gases, specialty gas cabinet, specialty gas cabinet australia, specialty gas cabinet China, specialty gas cabinet companies in taiwan, Specialty gas cabinet cost, specialty gas cabinet india, specialty gas cabinet manufacturer india, Specialty gas cabinet price, specialty gas equipment, Specialty Gas Equipment and Regulators, specialty gas equipment manufacturer

- No Comments

What Is Fully Automatic Specialty Gas Cabinets With Gas Panel For NF3 Gas

Nitrogen Trifluoride (NF3) is a specialty gas that plays a vital role in modern high-tech industries, particularly in electronics manufacturing. As a strong oxidant with unique properties, NF3 requires careful handling and precise delivery systems to ensure safety and efficiency. Fully automatic specialty gas cabinets with gas panels are advanced solutions designed to meet these demands, providing a controlled environment for storing and managing NF3 gas. This article explores the purpose, features, and significance of these gas cabinets, emphasizing their role in industries that rely on NF3. From the gas’s applications to the specific safety considerations and benefits of automation, we will cover all aspects of this critical equipment in this article.

Introduction to NF3 and Its Uses

Nitrogen Trifluoride (NF3) is a colorless, odorless gas composed of one nitrogen atom bonded to three fluorine atoms. Stable at room temperature, it transforms into a powerful oxidant under specific conditions, making it both valuable and hazardous. NF3 has become indispensable in the electronics industry, where it is widely used in the production of semiconductors, flat panel displays, and solar cells.

In semiconductor manufacturing, NF3 serves as a cleaning agent for chemical vapor deposition (CVD) chambers. It effectively removes silicon-based residues and other contaminants, ensuring the precision and quality of microchips that power everything from smartphones to computers. Similarly, in flat panel display production—such as LCD and OLED screens—NF3 is employed for cleaning and etching, contributing to the clarity and performance of high-definition visuals. The gas also enhances the efficiency of thin-film solar cells by optimizing surface properties for better light absorption and energy conversion.

Beyond electronics, NF3 has applications in atmospheric research as a tracer gas due to its long lifespan and infrared absorption characteristics. As demand for NF3 grows with advancements in technology, so does the need for equipment capable of handling it safely and efficiently. This is where fully automatic specialty gas cabinets come into play.

The Role of Gas Cabinets in Handling Hazardous Gases

Gas cabinets are specialized enclosures designed to store and manage hazardous gases like NF3 in industrial settings. Their primary purpose is to create a secure, controlled environment that prevents leaks, minimizes exposure risks, and ensures safe gas delivery. Typically constructed from durable materials such as steel, gas cabinets house gas cylinders and related equipment, such as regulators and valves, within a ventilated space.

The importance of gas cabinets lies in their ability to mitigate the dangers associated with toxic, flammable, or reactive gases. For example, if a leak occurs, the cabinet’s exhaust system channels the gas to a safe location, preventing accumulation in the workspace. This is critical for a gas like NF3, which can pose significant safety risks if mishandled. Gas cabinets also protect equipment from external factors, such as physical damage or environmental contamination, ensuring a consistent gas supply for production processes.

In industries like semiconductor manufacturing, where precision and safety are non-negotiable, gas cabinets are a cornerstone of gas management infrastructure. They not only enhance workplace safety but also help facilities comply with strict regulations governing hazardous materials.

Features of Fully Automatic Gas Cabinets

Fully automatic gas cabinets take gas management to the next level by incorporating advanced automation technologies. These systems are engineered to reduce human intervention, minimize errors, and optimize performance. Below are some key features that define fully automatic gas cabinets:

– Automated Purging Systems: These ensure that the cabinet and gas lines are free of contaminants before and after use. For NF3, maintaining gas purity is essential, as impurities can compromise the quality of electronic components.

– Pressure Regulation: Automatic controls maintain consistent gas pressure, delivering NF3 at the precise levels required for specific applications. This eliminates the need for manual adjustments and enhances process reliability.

– Integration with Facility Systems: Many fully automatic gas cabinets connect to centralized facility management systems, allowing operators to monitor gas usage, detect anomalies, and manage operations remotely.

– Emergency Shutdown Capabilities: In the event of a leak or other hazard, the cabinet can automatically isolate the gas supply, preventing escalation and protecting personnel and equipment.

These features make fully automatic gas cabinets ideal for handling specialty gases like NF3, where precision, safety, and efficiency are paramount. By automating critical functions, these systems reduce downtime, improve productivity, and provide peace of mind in high-stakes environments.

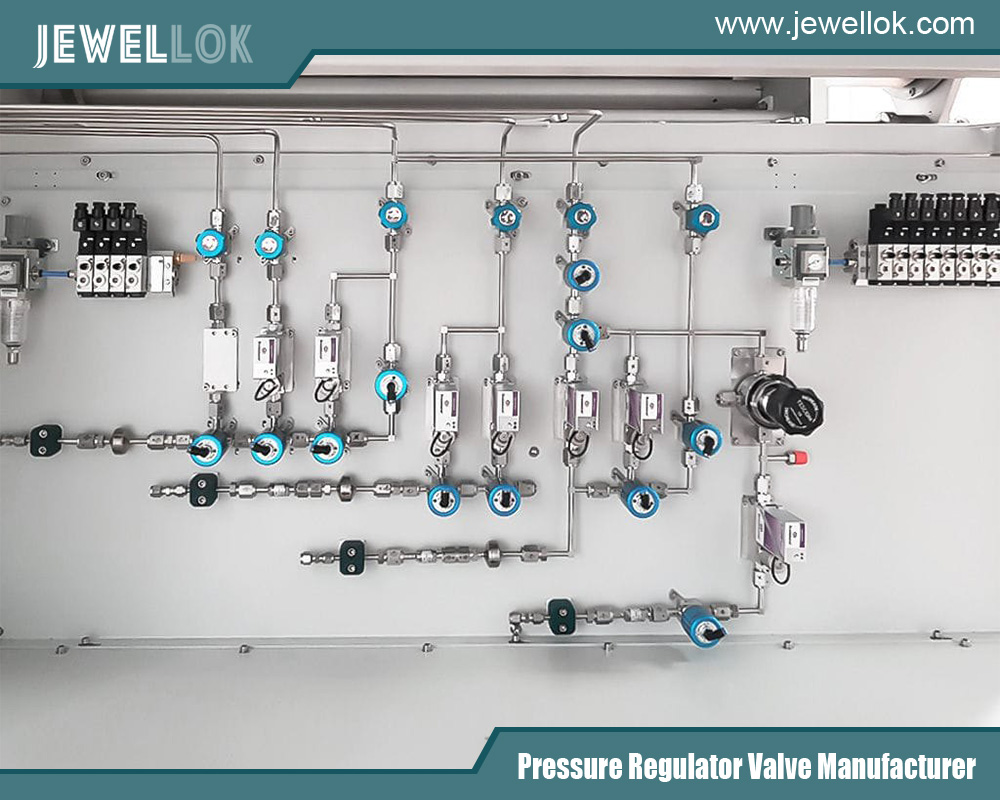

The Gas Panel and Its Functions

The gas panel is the operational hub of a fully automatic gas cabinet, serving as the interface for controlling and monitoring gas delivery. Typically mounted on the front of the cabinet, the gas panel is equipped with a range of components designed to manage gas flow, pressure, and safety. These may include:

– Valves: Manual and automatic valves regulate the flow of NF3, allowing operators to start, stop, or adjust delivery as needed.

– Pressure Gauges and Flow Meters: These provide real-time data on gas pressure and flow rates, ensuring the system operates within specified parameters.

– Touchscreen Interfaces: In advanced systems, digital displays offer detailed control and monitoring capabilities, often integrating with the cabinet’s automation features.

– Safety Devices: Components like pressure relief valves and leak detectors enhance the panel’s role in maintaining a safe environment.

For NF3-specific applications, the gas panel may incorporate corrosion-resistant materials and high-purity fittings to prevent reactions and contamination. The panel’s integration with the cabinet’s automation systems enables seamless management of purging, pressure regulation, and emergency responses. In semiconductor facilities, where precise gas delivery is critical, the gas panel ensures that NF3 is supplied consistently and safely, supporting uninterrupted production.

Specific Considerations for NF3 Gas Cabinets

NF3’s unique properties necessitate tailored design considerations for gas cabinets. As a strong oxidant, NF3 can react with certain materials, requiring the use of corrosion-resistant components. Stainless steel is commonly employed for the cabinet structure, piping, and fittings to withstand potential chemical interactions and ensure long-term durability.

Purity is another critical factor. In electronics manufacturing, even trace impurities in NF3 can degrade product quality, so gas cabinets must feature high-purity components and rigorous purging systems. The ventilation system must also be designed to handle NF3-specific risks, such as exothermic reactions with incompatible substances, ensuring that any leaked gas is safely exhausted.

Precision control is equally important. NF3 applications often require exact flow rates and pressures, which fully automatic gas cabinets achieve through advanced regulators and sensors. Regular maintenance and calibration are essential to maintain these standards, ensuring the cabinet performs reliably over time.

Safety Features and Regulations

Safety is a top priority when handling NF3, and fully automatic gas cabinets are equipped with multiple features to address potential risks:

– Leak Detection Sensors: These devices identify gas leaks in real time, triggering alarms and, if necessary, automatic shutdowns to contain the issue.

– Fire Suppression Systems: Integrated systems using inert gases or specialized agents can extinguish fires caused by leaks or reactions.

– Emergency Shut-Off Valves: These allow for immediate isolation of the gas supply in emergencies, minimizing harm.

Compliance with industry standards is also critical. The National Fire Protection Association (NFPA) sets guidelines, such as NFPA 55, for the storage and handling of compressed gases, including requirements for gas cabinets. Local building codes and occupational safety regulations may impose additional mandates. Adhering to these standards ensures not only safety but also operational continuity by avoiding regulatory penalties.

Benefits of Using Fully Automatic Gas Cabinets for NF3

The adoption of fully automatic gas cabinets for NF3 offers numerous advantages:

– Enhanced Safety: Automation reduces human error, while real-time monitoring and emergency features mitigate risks, protecting personnel and facilities.

– Improved Efficiency: Automated purging and pressure control streamline gas delivery, minimizing downtime and boosting productivity.

– Cost Savings: Precise gas usage tracking and reduced maintenance needs can lower operational costs over time.

– Regulatory Compliance: These systems help facilities meet strict safety and quality standards, avoiding fines and ensuring market competitiveness.

In industries like semiconductor manufacturing, where NF3 is a linchpin, these benefits translate into higher reliability and better outcomes, making fully automatic gas cabinets a worthwhile investment.

Conclusion and Future Outlook

Fully automatic specialty gas cabinets with gas panels are indispensable for managing NF3 gas in industries that demand precision and safety. By combining robust safety features, advanced automation, and tailored design, these cabinets ensure that NF3 is handled efficiently and securely, supporting the production of cutting-edge electronics and renewable energy solutions.

Looking ahead, the evolution of gas cabinet technology is likely to continue. Innovations such as AI-driven monitoring, predictive maintenance, and eco-friendly designs could further enhance performance and sustainability. As NF3’s role in technology expands, fully automatic gas cabinets will remain a critical tool, adapting to meet the challenges of tomorrow’s industries while safeguarding today’s operations.

For more about what is fully automatic specialty gas cabinets with gas panel for nf3 gas, you can pay a visit to Jewellok at https://www.jewellok.com/product/semi-automatic-gas-cabinet-gas-panels-high-purity-gas-delivery-systems-jw-200-gc/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

Scrubber Gas Cabinet Scrubber Tail Gas Treatment Cabinet Vent Gas Scrubber System Heat-Filter Burn Box Gas Scrubber/Abatement System

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

High Purity High Pressure 316 Stainless Steel Ball Valves JBV1 Series From High Pressure Ball Valve Manufacturer And Supplier In China

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

JF Series In-Line Gas Filters | High Purity High Precision High Flow Semiconductor Gas Filter Gas Filtration & Purification