Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

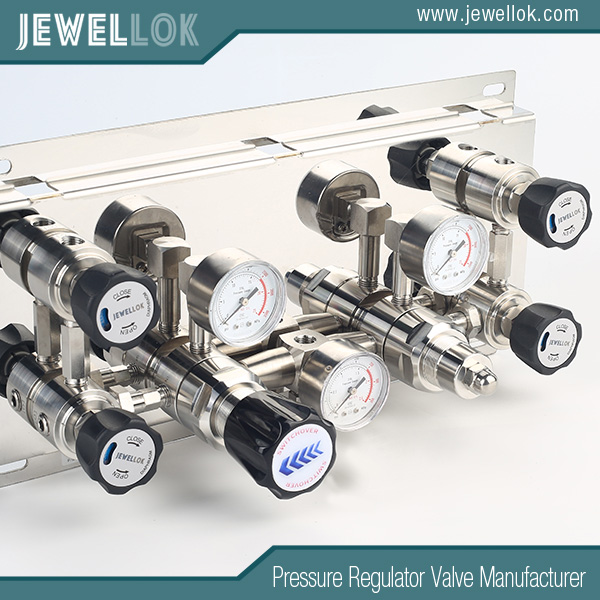

What Is Semiconductor Valve Manifold Box Gas Pressure Regulators

- Pressure Regulator Valve Manufacturer

- gas valve manifold box, Gas Valve Manifold Boxes, oxygen manifold system, semiconductor valve manifold box, semiconductor valve manifold box diaphragm valves, semiconductor valve manifold box gas pressure regulators, ultra high purity manifolds, valve manifold box, valve manifold box semiconductor, valve manifold panels, Valve Manifold Panels and Boxes, vmb gas cabinet, vmb gas cabinet China, vmb gas cabinet factory, vmb gas cabinet manufacturer, vmb gas cabinet supplier, vmb valve manifold box, VMB Valve Manifold Panels And Boxes

- No Comments

What Is Semiconductor Valve Manifold Box Gas Pressure Regulators

In the intricate world of semiconductor manufacturing, precision is paramount. Every step of the process, from the deposition of thin films to the etching of microscopic patterns, relies on the exact control of various parameters, including the pressure of gases used in these processes. Semiconductor valve manifold box gas pressure regulators are critical components that ensure gases are delivered at the precise pressures required for optimal performance. These devices, housed within valve manifold boxes, manage the complex gas delivery systems that are the lifeblood of semiconductor fabrication facilities. This article explores the role, functionality, and significance of these regulators in the semiconductor industry, shedding light on their design, operation, and the latest advancements in this specialized field.

Overview of Semiconductor Manufacturing

Semiconductor manufacturing is a highly sophisticated process that involves creating integrated circuits (ICs) on silicon wafers through a series of precise steps. These steps transform raw materials into the tiny, powerful chips that power modern electronics, from smartphones to supercomputers. Among the critical elements in this process are the gases used in various stages, such as chemical vapor deposition (CVD), etching, and ion implantation. These gases must be delivered at exact pressures to ensure the uniformity, quality, and reliability of the semiconductor devices being produced.

The Role of Gases in Semiconductor Processes

Chemical Vapor Deposition (CVD): In CVD, gases like silane (SiH₄) and ammonia (NH₃) are used to deposit thin films of materials, such as silicon dioxide or silicon nitride, onto the wafer surface. The pressure at which these gases are delivered directly affects the deposition rate, film thickness, and material properties. Too high or too low a pressure can lead to uneven films or defects that compromise the chip’s performance.

Etching: Etching processes use gases such as chlorine (Cl₂) or sulfur hexafluoride (SF₆) to selectively remove material from the wafer, creating the intricate patterns that form the circuits. The pressure of these gases influences the etch rate and the precision of the etched features. Inconsistent pressure can result in over-etching or under-etching, both of which degrade the final product.

Ion Implantation: This process introduces dopant atoms into the semiconductor material to alter its electrical properties, enabling it to conduct electricity in specific ways. Gases are used to generate ions, and precise pressure control is necessary to achieve the desired implantation depth and concentration. Variations in pressure can disrupt the doping process, affecting the chip’s functionality.

The Need for Precision

The sensitivity of these processes to gas pressure cannot be overstated. Even a slight deviation from the specified pressure can lead to defects, reduced yield (the percentage of functional chips produced), or inconsistent product quality. For example, in a modern semiconductor fab producing chips with feature sizes measured in nanometers, a pressure fluctuation of just a few millibars could ruin an entire batch of wafers, costing millions of dollars. Therefore, the ability to regulate gas pressure accurately and consistently is a cornerstone of successful semiconductor manufacturing.

Valve Manifold Boxes

A valve manifold box is a centralized unit that contains multiple valves, enabling the distribution of gases from one or more sources to multiple destinations within a semiconductor fabrication facility (fab). These boxes are essential for managing the complex gas delivery systems that supply various tools and process chambers, ensuring that each receives the right gas at the right time.

Purpose and Functionality

The primary purpose of a valve manifold box is to streamline gas distribution. Without such a system, individual gas lines would need to run from the source to each point of use, creating a tangled web of tubing that would be impractical in the confined, highly controlled space of a cleanroom. By centralizing gas flow control, manifold boxes reduce complexity, save space, and enhance safety and ease of maintenance.

Key Components

A typical valve manifold box includes the following components:

Valves: These can be pneumatic (air-operated), manual, or solenoid (electrically operated) valves that control the flow of gas to different parts of the system. They open, close, or adjust to direct gas where it’s needed.

Fittings and Tubing: These connect the valves and ensure leak-free operation, which is critical for maintaining gas purity and preventing contamination of the cleanroom environment.

Pressure Gauges and Sensors: These monitor pressure levels within the system, providing real-time data to operators or automated control systems to ensure everything is functioning within specifications.

Integrated Controllers or PLCs: In advanced systems, programmable logic controllers (PLCs) or other automation devices manage valve operations, ensuring precise and repeatable gas delivery without human intervention.

Use in Semiconductor Fabs

In semiconductor fabs, valve manifold boxes are often customized to meet the specific needs of the facility. The design takes into account the types of gases used (e.g., inert, reactive, or toxic), the number of process tools, and the layout of the cleanroom. For instance, a single manifold box might supply nitrogen to one tool, silane to another, and argon to a third, all while maintaining strict isolation to prevent cross-contamination.

Gas Pressure Regulators

Gas pressure regulators are devices designed to reduce and control the pressure of gas from a high-pressure source (such as a cylinder or bulk supply) to a lower, stable pressure suitable for use in semiconductor processes. In this context, they are the workhorses that ensure gases reach the wafer at the exact pressure required, no matter the fluctuations in the source pressure.

Types of Regulators

There are two main types of gas pressure regulators commonly used:

Single-Stage Regulators: These reduce pressure in a single step and are suitable for applications where the inlet pressure is relatively constant. They are simpler and less expensive but may struggle to maintain output stability if the source pressure varies significantly.

Dual-Stage Regulators: These reduce pressure in two steps, offering greater precision and stability even when the inlet pressure fluctuates (e.g., as a gas cylinder empties). They are preferred in semiconductor applications where consistency is critical.

Key Features for Semiconductor Applications

Gas pressure regulators used in semiconductor manufacturing must meet stringent requirements:

High Precision and Stability: Even minor pressure fluctuations can disrupt processes, so regulators must maintain consistent output over time, often within tolerances of a few millibars or less.

Low Dead Volume: This minimizes the amount of gas trapped in the regulator, reducing waste and ensuring quick response to pressure changes—crucial in dynamic processes.

Material Compatibility: Regulators must be made from materials (typically high-grade stainless steel) that can withstand reactive, corrosive, or toxic gases like silane or chlorine without degrading or contaminating the gas stream.

Quick Response: Semiconductor processes often require rapid adjustments to gas flow and pressure. Regulators must respond swiftly without overshooting the target pressure, which could destabilize the system.

The accuracy and reliability of these regulators directly impact the quality and yield of semiconductor products, making them indispensable in the industry.

Integration in Semiconductor Applications

In semiconductor manufacturing, gas pressure regulators are integrated into valve manifold boxes to create a cohesive gas delivery system that meets the industry’s exacting standards. This integration is a feat of precision engineering, balancing functionality with the unique constraints of a semiconductor fab.

Design Considerations

Space Efficiency: Cleanrooms are expensive to build and maintain, with costs often exceeding $1,000 per square foot. Valve manifold boxes must be compact, fitting into tight spaces without sacrificing performance or accessibility.

Cleanliness: The semiconductor industry demands ultra-high purity (UHP) components to prevent particle contamination, which can ruin wafers. All parts of the gas delivery system, including regulators and valves, are meticulously cleaned—often electropolished—to minimize surface roughness and particle generation.

Safety: Many gases used in semiconductor manufacturing are hazardous. For example, silane is pyrophoric (it ignites spontaneously in air), while chlorine is highly toxic. Valve manifold boxes must include fail-safes, leak detection systems, and emergency shutoff mechanisms to protect personnel and equipment.

Specific Requirements

Ultra-High Purity (UHP) Components: To maintain gas purity, all wetted surfaces (those in contact with the gas) must be made from inert, high-quality materials. This prevents outgassing or reactions that could introduce impurities.

Compatibility with Diverse Gases: Semiconductor processes use a wide range of gases, from inert ones like nitrogen to highly reactive ones like silane. Regulators must handle this diversity without degradation or cross-contamination.

Rapid Pressure Adjustments: Some processes require quick changes in gas pressure (e.g., switching from deposition to etching). Regulators must adjust rapidly while maintaining stability and accuracy to avoid disruptions.

Challenges

Miniaturization: As semiconductor devices shrink to nanometer scales, fabs are under pressure to reduce the footprint of support equipment. This drives the need for smaller, more efficient regulators and manifold systems without compromising performance.

Reliability: Gas delivery systems must operate flawlessly for extended periods—often years—with minimal maintenance, as downtime in a fab can cost hundreds of thousands of dollars per hour.

The seamless integration of gas pressure regulators into valve manifold boxes exemplifies the precision and innovation required in semiconductor manufacturing, where every detail matters.

Advancements and Trends

The field of semiconductor valve manifold box gas pressure regulators is continually evolving, driven by the relentless pace of semiconductor technology advancements. These innovations are enhancing performance, reliability, and efficiency, helping manufacturers keep up with shrinking feature sizes and increasingly complex processes.

New Materials

Advanced Alloys and Coatings: Manufacturers are developing regulators made from specialized alloys or with advanced surface treatments (e.g., chromium or nickel coatings) to improve corrosion resistance and reduce particle generation. These materials extend equipment lifespan and maintain gas purity, critical for next-generation chips.

Smart Technologies

Sensors and IoT Capabilities: Modern regulators are increasingly equipped with sensors that monitor pressure, flow, and temperature in real time. When integrated with Internet of Things (IoT) systems, this data enables predictive maintenance—fixing issues before they cause failures—and optimizes system performance.

Automated Control Systems: The use of PLCs and other automation technologies allows for precise, repeatable control of gas delivery, reducing human error and improving process consistency.

Miniaturization

Compact Designs: As fabs strive to maximize space efficiency, there is a growing demand for smaller regulators and manifold systems. Advances in design and manufacturing (e.g., 3D printing or microfabrication) are producing compact yet highly functional components that fit into tight cleanroom spaces.

Automation

Automated Valve Control: Advanced manifold boxes now feature automated valve sequencing and control, enabling rapid and precise adjustments to gas flow and pressure. This is particularly valuable in processes that require frequent changes, enhancing throughput and flexibility.

These advancements are not only improving the performance of gas delivery systems but also aligning with broader trends like Industry 4.0, where automation and data-driven decision-making are transforming manufacturing.

Conclusion

Semiconductor valve manifold box gas pressure regulators are unsung heroes in the highly controlled world of semiconductor manufacturing. By ensuring that gases are delivered at precise pressures, these devices underpin the quality, yield, and efficiency of the processes that produce the chips powering our digital age. From their role in managing complex gas delivery systems to their integration into compact, ultra-clean manifold boxes, they embody the precision and reliability that the industry demands.

As semiconductor technology advances—pushing toward smaller feature sizes, new materials, and more intricate designs—the need for innovative gas delivery solutions will only grow. Developments in materials, smart technologies, and automation are paving the way for the next generation of regulators, ensuring that manufacturers can meet the challenges of tomorrow’s technologies. In this ever-evolving field, semiconductor valve manifold box gas pressure regulators remain a vital link in the chain of innovation, quietly enabling the creation of the devices that shape our world.

For more about semiconductor valve manifold box gas pressure regulators, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-cabinet/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

Stainless Steel Mini Elbow Mini Tee Mini Cross Mini Tribow Ultrahigh Purity Mini Butt Weld Fittings

-

Semi Automatic Oxygen Nitrogen Helium Argon Gas Changeover Manifold Manual Gas Changeover Manifold Panel For Gas Cylinders

-

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

Semi-Automatic VMB Gas Cabinet With Semiconductor Valve Manifold Box Diaphragm Valves And Gas Pressure Regulators

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory