Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What Is The Automatic Changeover Manifold For Specialty Gas?

- Pressure Regulator Valve Manufacturer

- Gas Manifold for Oxygen Supply, Gas manifold systems and tapping points, Gas manifold systems with automatic switch-over, High Purity Automatic Manifold, High Purity Changeover Manifold, High Purity Changeover Manifold Manufacturer, High Purity Semi-Auto Stainless Steel Changeover Manifolds, high purity stainless steel manifold, High-Purity Single-Source Dual-Stage Gas Manifold, Industrial Gas Manifold Systems, Medical Gas Manifold Systems, Oil and Gas Manifolds, Stainless Steel 316 Manifold Valves Manufacturer, Stainless Steel 316 Manifold Valves Supplier, Stainless Steel Manifolds, Ultra High Purity Valves Diaphragm and Bellows Manifold, Wholesale Stainless Steel Manifold Manufacturers

- No Comments

What Is The Automatic Changeover Manifold For Specialty Gas?

In industries and applications where specialty gases play a vital role, maintaining a continuous and reliable gas supply is essential. Specialty gases, such as high-purity gases, calibration gases, and medical gases, are utilized across diverse fields including healthcare, laboratories, and manufacturing. Interruptions in their supply can lead to operational delays, compromised outcomes, or even safety risks. To address this challenge, the automatic changeover manifold emerges as a critical solution. This sophisticated system ensures an uninterrupted flow of specialty gas by seamlessly switching between gas sources. In this article, we will explore the automatic changeover manifold in detail—its definition, functionality, components, benefits, and its specific importance for specialty gases.

Understanding Manifolds in Gas Systems

Before diving into the specifics of automatic changeover manifolds, it’s helpful to understand what a manifold is in the context of gas systems. A manifold is a device that connects multiple gas cylinders to a single outlet, enabling the distribution of gas from various sources. This setup is particularly useful when a single cylinder lacks the capacity to meet demand or when redundancy is needed for reliability. Manifolds come in two primary types: manual, which require an operator to switch between cylinders, and automatic, which perform this task without human intervention. The automatic changeover manifold, the focus of this article, builds on this concept to provide a seamless and efficient solution for gas supply management.

Why Automatic Changeover is Essential for Specialty Gases

Specialty gases are often employed in applications where continuity is non-negotiable. Consider a hospital, where medical gases like oxygen are critical for patient care—any interruption could have dire consequences. Similarly, in semiconductor manufacturing, high-purity gases must be supplied consistently to maintain product quality. Manual changeover systems, while effective in simpler scenarios, depend on human action, which introduces the risk of delays or errors. Automatic changeover manifolds eliminate these concerns by detecting when a primary gas source is running low and switching to a backup source autonomously. This capability is especially valuable for specialty gases, where even a momentary lapse can disrupt critical processes or compromise safety.

The need for such systems becomes even clearer when considering the unique properties of specialty gases. These gases often require high purity levels or specific handling due to their reactivity or use in precision applications. An automatic changeover manifold ensures that these stringent requirements are met without interruption, making it an indispensable tool in industries that rely on specialty gases.

How an Automatic Changeover Manifold Operates

At its core, an automatic changeover manifold is designed to maintain a steady gas supply by transitioning between two banks of cylinders: a primary bank and a secondary bank. The system draws gas from the primary bank until its pressure drops below a predefined threshold, signaling that it is nearly depleted. At this point, the manifold automatically shifts to the secondary bank, ensuring a continuous flow. Meanwhile, it may alert operators to replace or refill the primary bank, allowing for proactive maintenance without disrupting the gas supply.

This process relies on a combination of mechanical and electronic components working in harmony. Typically, a pressure switch or differential pressure sensor monitors the gas levels in the primary bank. When the pressure falls below the set point, the sensor triggers a control unit, which activates solenoid valves to redirect the gas flow from the secondary bank. This transition is engineered to be smooth, maintaining stable outlet pressure to prevent disturbances in downstream applications. Some advanced systems also feature automatic purging to clear residual gas from the lines, further safeguarding the purity and quality of the supply.

Key Components of an Automatic Changeover Manifold

The functionality of an automatic changeover manifold depends on several essential components, each contributing to its reliability and efficiency:

– Pressure Regulators: These devices ensure that gas is delivered at a consistent pressure, regardless of fluctuations in the cylinder. They are critical for applications requiring precise pressure control.

– Check Valves: Positioned to prevent backflow, check valves ensure that gas moves in one direction only, avoiding contamination between the primary and secondary banks.

– Solenoid Valves: These electrically operated valves open or close to direct gas flow, enabling the automatic switch between cylinder banks.

– Pressure Sensors: These monitor cylinder pressure and signal the control unit when a changeover is needed, acting as the system’s detection mechanism.

– Control Unit: Serving as the system’s central processor, the control unit interprets sensor data and coordinates the changeover process. It may also manage additional features like alarms.

– Alarms and Indicators: These provide visual or audible notifications to operators, indicating when a changeover occurs or when maintenance is required.

Together, these components create a robust system capable of managing gas supply with minimal human oversight.

Benefits of Automatic Changeover Manifolds for Specialty Gases

The adoption of automatic changeover manifolds offers numerous advantages, particularly when handling specialty gases:

– Uninterrupted Supply: By ensuring a continuous flow of gas, these systems prevent disruptions that could halt critical operations or compromise results.

– Minimized Downtime: Automatic switching eliminates the need for manual intervention, allowing processes to continue seamlessly while depleted cylinders are replaced at a convenient time.

– Enhanced Safety: Reducing the frequency of manual cylinder handling lowers the risk of accidents, such as those associated with high-pressure systems.

– Operational Efficiency: Operators can plan cylinder replacements strategically, optimizing gas inventory management and reducing urgency-driven interventions.

– Consistent Delivery: Stable pressure and flow rates are maintained, which is vital for applications like analytical testing or manufacturing that demand precision.

These benefits collectively enhance the reliability and performance of systems dependent on specialty gases, making automatic changeover manifolds a valuable investment.

Special Considerations for Specialty Gases

Specialty gases often come with unique requirements that necessitate tailored design considerations in automatic changeover manifolds. One primary concern is purity—many specialty gases, such as those used in semiconductor production or laboratory analysis, must remain uncontaminated to be effective. To achieve this, manifolds are constructed with high-purity components, including regulators, valves, and tubing made from materials that resist contamination. Proper purging protocols are also essential to remove any residual gas or impurities from the system during changeovers.

Additionally, some specialty gases are reactive or corrosive, requiring manifolds built from compatible materials like stainless steel or specialized alloys. For ultra-high purity applications, features such as electropolished surfaces or gas filters may be incorporated to minimize particle generation and maintain gas integrity. Dead volume—the unused space within the system where gas can become trapped—must also be minimized to ensure rapid, efficient changeovers without pressure fluctuations. These considerations ensure that the manifold meets the exacting standards of specialty gas applications.

Applications of Automatic Changeover Manifolds

Automatic changeover manifolds find use across a wide range of industries, each benefiting from their ability to deliver a reliable gas supply:

– Healthcare: In hospitals, manifolds manage medical gases like oxygen and nitrous oxide. For instance, if a primary oxygen tank runs low, the system switches to a reserve tank, ensuring uninterrupted patient care.

– Laboratories: Research facilities rely on high-purity gases for techniques like gas chromatography. An automatic changeover manifold prevents supply interruptions that could ruin experiments or delay progress.

– Semiconductor Manufacturing: The production of microchips demands ultra-pure gases for processes like chemical vapor deposition. Manifolds maintain both purity and continuity, supporting high-yield manufacturing.

– Food and Beverage: Nitrogen and carbon dioxide are used to preserve packaged goods by displacing oxygen. Automatic changeover ensures consistent gas availability, maintaining product quality.

– Welding and Metal Fabrication: Shielding gases like argon protect welds from contamination. A manifold allows welders to work without pausing to replace cylinders, boosting productivity.

These examples highlight the versatility of automatic changeover manifolds and their critical role in diverse settings.

Choosing the Right Automatic Changeover Manifold

Selecting an appropriate manifold for a specialty gas application involves evaluating several factors:

– Gas Compatibility: The manifold’s materials must withstand the gas’s properties, such as corrosiveness or reactivity, to prevent degradation or contamination.

– Flow Rate: The system should support the application’s required flow rate without compromising performance.

– Pressure Requirements: Regulators must deliver gas at the correct pressure, tailored to the process’s needs.

– Purity Standards: For high-purity gases, the manifold should minimize contamination risks through design and materials.

– Monitoring Features: Alarms or remote monitoring capabilities may be necessary for real-time oversight, especially in critical applications.

– Compliance: The manifold must meet relevant industry standards, such as those for medical or hazardous gases.

By addressing these criteria, users can ensure the manifold aligns with their operational demands.

The Future of Automatic Changeover Manifolds

Looking ahead, technological advancements are poised to enhance automatic changeover manifolds further. The integration of smart sensors and Internet of Things (IoT) technology enables real-time monitoring of gas levels and system health, accessible remotely via digital platforms. Predictive analytics can also forecast usage patterns, optimizing cylinder replacement schedules and reducing waste. These innovations promise to make manifolds even more efficient and reliable, reinforcing their importance in specialty gas management.

Conclusion

The automatic changeover manifold stands as a cornerstone in the delivery of specialty gases, offering a dependable solution for maintaining uninterrupted supply in critical applications. By automating the switch between gas sources, it enhances safety, efficiency, and consistency—qualities that are paramount in industries like healthcare, manufacturing, and research. As technology evolves, these systems will continue to advance, solidifying their role as an essential tool for organizations that depend on the precision and reliability of specialty gases. Whether ensuring patient safety or supporting cutting-edge production, automatic changeover manifolds deliver the assurance of a seamless gas supply.

For more about what is the automatic changeover manifold for specialty gas, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-changeover-manifold/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

JF Series In-Line Gas Filters | High Purity High Precision High Flow Semiconductor Gas Filter Gas Filtration & Purification

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

-

772L Male Branch Tee | Stainless Steel High-Purity Tube Fitting Male Branch Tee

-

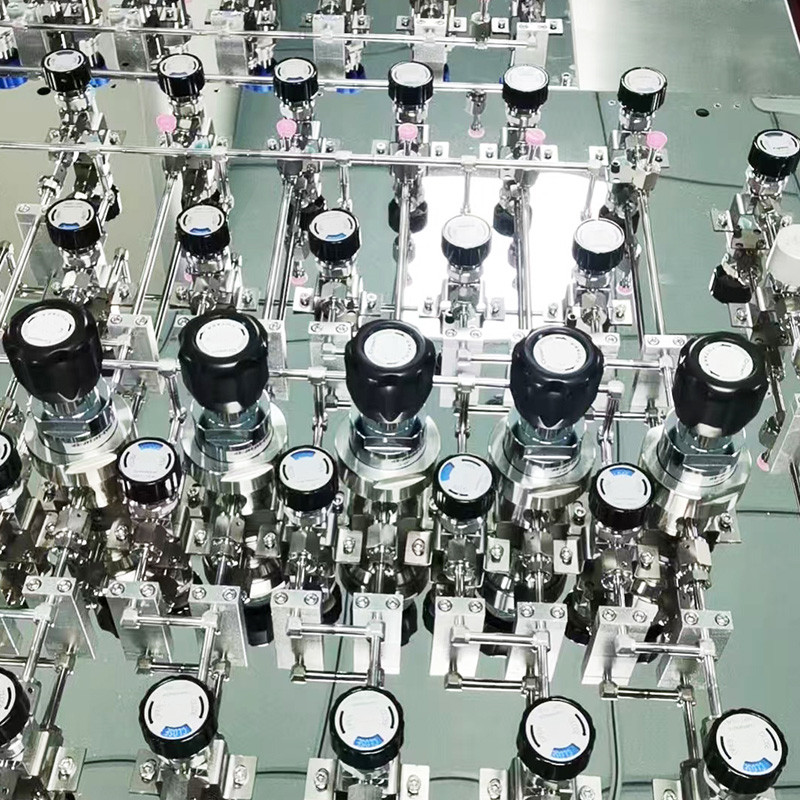

High Purity Semi-Auto Stainless Steel Changeover Manifold System, Nitrogen High Pressure Control Panel With Semiconductor Valve Manifold Box Diaphragm Valves

-

High Purity High Pressure Gas Cylinder Pressure Regulators Pressure Reducing Valve JSR-1E Series

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series