Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What is VMB Valve Manifold Box

- Pressure Regulator Valve Manufacturer

- custom hydraulic manifolds, gas regulator manifold, Gas Valve Manifold Boxes, hydrogen valve manifold, SiH4 NF3 NH3 Gas Valve Manifold Boxes, Valve Manifold Box for Gas System VMB, valve manifold box semiconductor, valve manifold panel, Valve Manifold Panels and Boxes, VMB Cabinet Gas Valve Manifold Box, vmb gas cabinet, vmb valve manifold box, vmb valve manifold box china, vmb valve manifold box germany, vmb valve manifold box indonesia, vmb valve manifold box japan, vmb valve manifold box korea, vmb valve manifold box malaysia, vmb valve manifold box manufacturer, vmb valve manifold box supplier, vmb valve manifold box thailand

- No Comments

What is VMB Valve Manifold Box

Introduction

In the realm of industrial gas and fluid distribution systems, the Valve Manifold Box (VMB) stands as a critical component designed to enhance safety, efficiency, and reliability. A VMB is essentially an enclosed system that takes a single source of gas or liquid and distributes it to multiple points of use, such as tools or processes in manufacturing environments. This distribution is achieved while incorporating features for venting, purging, and monitoring to ensure safe operation, particularly when handling hazardous, toxic, or high-purity substances. VMBs are commonly used in industries where precise control over gas flow is paramount, preventing contamination, leaks, or interruptions that could lead to costly downtime or safety hazards.

The primary function of a VMB is to split a bulk gas supply—whether hazardous or non-hazardous—into multiple outlets without compromising the integrity of the system. For instance, in semiconductor fabrication plants, where ultra-high purity gases are essential for processes like etching and deposition, VMBs ensure that gases like nitrogen, argon, or specialty chemicals are delivered consistently and safely. These boxes are often engineered with modular designs, allowing for configurations ranging from 4 to 8 or more “sticks”—individual gas lines equipped with valves and regulators. This modularity makes VMBs adaptable to various scales of operation, from small research labs to large-scale industrial facilities.

VMBs differ from simpler valve manifolds or panels (VMPs) in that they are fully enclosed boxes, providing an additional layer of protection through features like self-closing doors, fire sprinklers, and exhaust vents. They can be manual, semi-automatic, or fully automatic, with the latter incorporating programmable logic controllers (PLCs) for real-time monitoring and automated shutdowns in case of anomalies like excess flow or pressure spikes. The enclosure is typically constructed from robust materials such as welded steel, with safety glass windows for visual inspection, ensuring compliance with industry standards like those from SEMI (Semiconductor Equipment and Materials International) or UL approvals.

The importance of VMBs cannot be overstated in modern manufacturing. As industries push for higher efficiency and stricter safety regulations, these systems reduce the need for multiple independent gas lines, minimizing installation costs, space requirements, and potential failure points. According to market analyses, the global VMB market is projected to grow significantly, driven by expansions in semiconductors, biopharmaceuticals, and renewable energy sectors. This growth reflects the VMB’s role in enabling scalable, safe gas distribution in an era of increasingly complex industrial processes.

In essence, a VMB is more than just a distribution hub; it’s a safeguard that integrates control, monitoring, and safety into one compact unit. Understanding its components, workings, and applications reveals why it has become indispensable in high-stakes environments.

History and Evolution of VMBs

The development of Valve Manifold Boxes traces back to the evolving needs of industries reliant on precise gas handling, particularly in the semiconductor and electronics sectors. While exact origins are not well-documented in public records, the concept of manifold systems for fluid distribution has roots in early 20th-century industrial engineering, where simple valve arrays were used in oil refineries and chemical plants to manage flows. However, the specialized VMB as we know it today emerged in the late 1990s and early 2000s, coinciding with the boom in microelectronics and the demand for ultra-high purity (UHP) gas delivery systems.

One of the earliest notable announcements came in 2003 from Air Products, introducing a new liquid Valve Manifold Box with a common purge and vent header design aimed at cost savings while maintaining full functionality and safety. This innovation was tailored for semiconductor manufacturing, where processes require contamination-free environments. Prior to this, gas distribution often relied on decentralized setups, leading to inefficiencies and higher risks. The introduction of VMBs addressed these by centralizing control and incorporating safety features like automated purging.

By the mid-2000s, companies like Linde and Applied Energy Systems began offering advanced VMBs, with features such as semi-automatic controls and integrated monitoring. For example, in 2011, SEMI-GAS Systems updated their semi-automatic VMB designs to reduce costs, space, and utility demands, reflecting a shift toward more compact and efficient systems. This evolution was driven by the semiconductor industry’s growth, where fabs (fabrication plants) expanded rapidly, necessitating scalable gas distribution without proportional increases in infrastructure.

The 2010s saw further advancements, including high-flow models capable of handling up to 600 standard liters per minute (slpm), as highlighted in 2015 by SEMI-GAS for their 8-line fully automatic VMBs. Integration with PLCs and emergency shutdown systems became standard, influenced by stricter regulations from bodies like OSHA and EPA. The market expanded beyond semiconductors to include biopharma, solar, and aerospace, with global adoption in regions like Asia, where LCD and solar panel production surged.

Today, VMBs continue to evolve with smart technologies, such as IoT-enabled monitoring for predictive maintenance. Market forecasts indicate steady growth, with valuations rising from USD 1.2 billion in 2024 to USD 2.1 billion by 2033, at a CAGR of 7.5%. This trajectory underscores the VMB’s transformation from a niche tool to a cornerstone of modern industrial gas management.

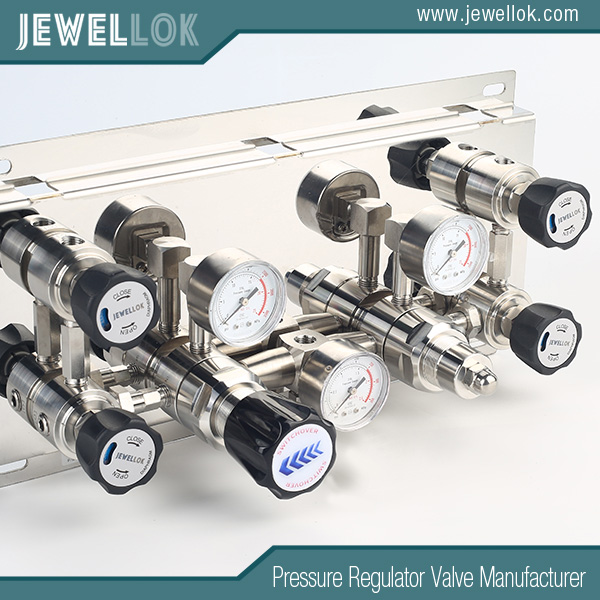

Components of a VMB

A Valve Manifold Box is composed of several interconnected components that work together to ensure safe and efficient gas distribution. At its core is the enclosure, typically made from welded 11-gauge steel for durability, featuring a self-closing, self-latching door, a 1/4-inch thick safety glass window for inspection, and UL-approved fire sprinklers for hazard mitigation. The enclosure may also include exhaust vents connected to building systems, especially for toxic gases, and mounting points for wall or rack installation.

The primary functional elements are the “sticks”—modular gas lines, often configured in 4, 6, 8, or up to 12 sticks per box. Each stick includes a series of valves: manual valves for basic control, pneumatic (air-operated) valves for automated operation, and emergency shutoff valves that activate during alarms. Between valves, purge ports allow for venting and flushing the system with inert gases like nitrogen to remove contaminants or hazardous residues.

Pressure regulators are crucial, reducing incoming high-pressure gas to suitable levels for downstream processes, while maintaining consistent flow. Gauges and transducers monitor pressure and flow in real-time, often integrated with mass flow meters or controllers for precise measurement. For advanced models, a PLC-based controller, such as the GigaGuard™ Emergency Shutdown System, oversees operations, with programmable inputs for sensors detecting high pressure, excess flow, or leaks.

Additional safety components include LED status lights, audible alarms, abort buttons, and optional sensors like door/window detectors, toxic gas monitors, UV/IR fire sensors, and panel heaters for low-vapor-pressure gases. Flame arresters and gas detectors may be added for high-risk applications. Materials are selected for compatibility, often stainless steel or polypropylene for corrosives, ensuring no contamination in UHP environments.

In liquid-handling VMBs, components like wye strainers and pressure regulators are included to filter impurities and stabilize flow. All assemblies are typically fabricated in cleanrooms to Class 100 standards, with rigorous testing for leaks and functionality. This comprehensive set of components makes VMBs versatile and reliable for demanding industrial uses.

How a VMB Works

The operation of a Valve Manifold Box revolves around controlled distribution, monitoring, and safety protocols. Gas enters the VMB from a bulk source, such as a cylinder or tank, through an inlet connected to the manifold. Inside, the gas is routed to multiple sticks, each acting as an independent channel.

Pressure regulators on each stick reduce the source pressure—often high—to the required operating range for tools or processes. Valves control the flow: manual valves allow operator intervention, while pneumatic valves respond to signals from the PLC for automated opening/closing. When a specific outlet needs gas, the corresponding valve opens, directing flow while isolating others to prevent cross-contamination.

Purging and venting are key for maintenance. To service a component without shutting down the entire system, operators use purge ports to flush the line with inert gas, venting residues through exhaust headers. This ensures safe isolation, minimizing downtime. Sensors monitor parameters; if anomalies occur, the PLC triggers shutdowns, closing valves and activating alarms.

In semi-automatic models, human interaction is minimal—operators set parameters via the controller, which handles routine operations. Fully automatic VMBs use advanced algorithms for continuous adjustment, supporting high flows up to 600 slpm. Overall, the VMB’s workflow emphasizes safety, efficiency, and reliability in gas handling.

Applications of VMBs

Valve Manifold Boxes find extensive use across industries requiring precise fluid or gas distribution. In semiconductors, VMBs distribute specialty gases like silane or ammonia to fabrication tools, ensuring UHP delivery for chip production. They are vital in LCD and solar panel manufacturing, handling corrosive gases in cleanrooms.

In biopharmaceuticals and healthcare, VMBs manage medical gases like oxygen or nitrogen for drug production and storage, with enclosures preventing contamination. Aerospace applications involve distributing fuels or hydraulics in testing facilities.

Chemical processing uses VMBs for hazardous liquids, providing safety in distribution to reactors. Research labs in universities employ them for experimental setups with rare gases. Water treatment and LED manufacturing also benefit from their efficiency in fluid control.

VMBs’ versatility extends to custom applications, like solvent or corrosive handling in polypropylene enclosures. Their role in minimizing risks makes them indispensable in high-purity, high-stakes environments.

Benefits and Advantages

VMBs offer numerous benefits, including enhanced safety through integrated shutdowns and venting, reducing accident risks. They minimize downtime by allowing isolated servicing, cutting costs.

Efficiency is boosted by centralizing distribution, saving space and piping. Customization ensures compatibility, while modularity supports scalability.

Overall, VMBs provide cost-effective, reliable solutions for complex gas systems.

Installation and Maintenance

Installation involves mounting the VMB near use points, connecting to sources and exhausts, and integrating with controls. Maintenance includes regular inspections, leak tests, and component replacements in clean environments. Rail-mounted designs ease access.

Future Trends

Future VMBs will incorporate AI for predictive maintenance and IoT for remote monitoring, aligning with Industry 4.0. Sustainable materials and higher flow capacities will address green manufacturing demands.

Conclusion

In summary, the VMB is a vital innovation in gas distribution, blending safety, efficiency, and adaptability. Its continued evolution promises even greater industrial impacts.

For more about what is vmb valve manifold box, you can pay a visit to Jewellok at https://www.jewellok.com/product/semi-automatic-vmb-gas-cabinet-with-semiconductor-valve-manifold-box-diaphragm-valves-and-gas-pressure-regulators/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

UHP Metal Gasket Face Seal Fittings Vacuum Coupling Metal Face Seal Join Long Gland And Short Gland

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

Manual Gas Rack High Purity Gas Delivery Systems JW-100-GR

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection