Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Which Gas Pressure Regulator is Best for Laboratory Use?

- Pressure Regulator Valve Manufacturer

- gas pressure regulator adjustment, gas pressure regulator china, gas pressure regulator manufacturers, gas pressure regulator market, gas pressure regulator suppliers, Gas Pressure Regulator Valve, gas pressure regulators market, high flow uhp gas pressure regulators, high purity gas pressure regulators, hydrogen gas pressure regulator, industrial gas pressure regulator, industrial gas pressure regulator manufacturers, natural gas pressure regulator factory, natural gas pressure regulator manufacturer, natural gas pressure regulator manufacturers, nitrogen gas pressure regulator, oil and gas pressure regulator stainless steel, pharmaceutical gas pressure regulator, semiconductor valve manifold box gas pressure regulators, specialty gas pressure regulator, stainless steel gas pressure regulator, uhp 316l stainless steel gas pressure regulators, uhp bulk gas pressure regulators

- No Comments

Which Gas Pressure Regulator is Best for Laboratory Use?

In laboratory environments, precision, safety, and reliability are paramount. Gas pressure regulators play a critical role in managing the flow and pressure of gases used in experiments, analytical instruments, and various scientific processes. These devices ensure that gases are delivered at consistent pressures from high-pressure cylinders or pipelines to sensitive equipment, preventing damage, leaks, or hazardous situations. Choosing the best gas pressure regulator for laboratory use involves understanding the specific requirements of the lab, the types of gases involved, and the operational demands.

Gas pressure regulators function by reducing the inlet pressure from a source (like a compressed gas cylinder) to a lower, stable outlet pressure. They are essential in fields such as chemistry, biology, physics, and materials science, where gases like nitrogen, oxygen, helium, hydrogen, and carbon dioxide are commonly used. For instance, in gas chromatography, a stable pressure is crucial for accurate separation of compounds. Similarly, in cell culture incubators, precise control of CO2 levels maintains optimal growth conditions.

The market offers a variety of regulators, from basic single-stage models to advanced electronic versions. However, not all are suited for laboratory applications, where factors like contamination control, corrosion resistance, and fine pressure adjustment are key. This article explores the different types of gas pressure regulators, evaluates their suitability for lab use, and provides guidance on selecting the best one. We will delve into technical specifications, performance metrics, and practical considerations to help lab managers and researchers make informed decisions.

Understanding Gas Pressure Regulators

At their core, gas pressure regulators consist of a loading mechanism (such as a spring or dome), a sensing element (like a diaphragm or piston), and a control element (valve). When the outlet pressure drops below the set point, the sensing element activates the control element to allow more gas flow, restoring equilibrium. Conversely, if pressure rises, the valve restricts flow.

Regulators are classified based on stages, materials, and control mechanisms:

- Single-Stage Regulators: These reduce pressure in one step. They are simple, cost-effective, and suitable for applications where inlet pressure remains relatively constant. However, they suffer from “supply pressure effect” or “droop,” where outlet pressure varies with changes in inlet pressure or flow rate.

- Two-Stage Regulators: These perform pressure reduction in two sequential stages, providing greater stability. The first stage reduces high inlet pressure to an intermediate level, and the second stage fine-tunes it to the desired outlet. They minimize droop and are ideal for labs with fluctuating cylinder pressures.

- Pilot-Operated Regulators: Used for high-flow applications, these employ a pilot valve to control the main valve, offering precise regulation at higher capacities.

- Electronic Regulators: These integrate sensors and actuators for digital control, often with feedback loops for ultra-precise pressure maintenance. They are programmable and can interface with lab automation systems.

Materials are another critical aspect. Regulators for corrosive gases like ammonia or chlorine require stainless steel or Hastelloy bodies, while non-corrosive gases like helium can use brass. Diaphragms may be made of neoprene, Viton, or stainless steel for compatibility and to prevent gas permeation.

In laboratories, regulators must comply with standards such as those from the Compressed Gas Association (CGA) for connections and ISO 9001 for quality. Safety features like pressure relief valves, burst discs, and flashback arrestors are non-negotiable, especially for flammable gases.

Key Factors in Selecting a Regulator for Laboratory Use

Selecting the optimal regulator involves balancing several technical parameters:

Pressure Range and Accuracy

Laboratories often require outlet pressures from as low as 0.1 psi for delicate instruments to 500 psi or more for high-pressure reactions. Accuracy is measured as a percentage of the set pressure; for example, a regulator with ±1% accuracy at 100 psi maintains pressure between 99 and 101 psi.

Two-stage regulators excel here, with droop typically less than 0.5% compared to 5-10% in single-stage models. For ultra-low pressures, dome-loaded regulators provide better control by using gas pressure instead of a spring.

Flow Rate Capacity

Flow rate, expressed in standard cubic feet per hour (SCFH) or liters per minute (LPM), must match the lab’s needs. Over-specifying can lead to instability, while under-specifying causes pressure drops. For example, a mass spectrometer might need 1-5 LPM of helium, whereas a flame atomic absorption spectrometer could require 10-20 LPM of acetylene.

Cv (flow coefficient) values indicate capacity; higher Cv means better flow at a given pressure drop. Labs should calculate required Cv using formulas like Cv = Q / √(ΔP SG), where Q is flow rate, ΔP is pressure drop, and SG is specific gravity.

Gas Compatibility and Purity

Gases vary in reactivity: inert gases like argon pose few issues, but reactive ones like hydrogen demand regulators free of organic lubricants to avoid contamination or explosions. High-purity applications, such as semiconductor fabrication labs, require electropolished stainless steel internals to minimize outgassing and particle generation.

Purity levels are denoted as, e.g., 99.999% (five nines), and regulators must not introduce impurities. Tied-diaphragm designs prevent stem leakage, enhancing purity.

Safety and Reliability

Labs handle hazardous gases, so regulators should include overpressure protection. Relief valves vent excess pressure, while gauges allow monitoring. For toxic gases, captured vent designs direct exhaust to fume hoods.

Reliability involves mean time between failures (MTBF); reputable manufacturers offer MTBF > 1 million cycles. Certifications like ATEX for explosive environments or FDA for biomedical labs add assurance.

Cost and Maintenance

Initial costs range from $50 for basic brass single-stage to $2000+ for electronic two-stage models. Total ownership cost includes maintenance: diaphragms wear out, requiring periodic replacement. Easy-to-service designs with modular components reduce downtime.

Comparing Types of Regulators

To determine the best for labs, let’s compare common types:

Single-Stage vs. Two-Stage

Single-stage regulators are compact and inexpensive, ideal for short-term experiments with stable supply pressures. However, in labs where cylinders deplete over time (inlet pressure drops from 2200 psi to 100 psi), outlet pressure can vary by 10-20 psi, affecting results.

Two-stage regulators maintain outlet pressure within 1-2 psi across the cylinder’s life, making them superior for precision work like HPLC (high-performance liquid chromatography). A study of regulator performance (based on general industry data) shows two-stage models have 5-10 times lower droop.

Piston vs. Diaphragm Sensing

Piston regulators handle higher pressures (up to 6000 psi) and are durable for abrasive gases but can leak if seals fail. Diaphragm types offer better sensitivity for low-pressure control and are less prone to leakage, preferred in clean labs.

Manual vs. Electronic Control

Manual regulators use knobs for adjustment, sufficient for most setups. Electronic ones, with PID (proportional-integral-derivative) controllers, achieve ±0.01 psi stability, integrating with LabVIEW or similar software. For automated labs, electronic regulators are best, though they require power and are more expensive.

Brand-wise, companies like Swagelok, Tescom, and Victor offer lab-grade models. Swagelok’s KPR series (two-stage, stainless steel) is popular for its low dead volume and high purity. Tescom’s ER5000 electronic regulator provides remote control, ideal for glovebox applications.

Best Practices for Laboratory Implementation

Once selected, proper installation and use maximize performance:

- Installation: Use CGA-standard fittings to match gas type (e.g., CGA-580 for helium). Install in ventilated areas, away from ignition sources. Purge lines before use to remove air or moisture.

- Calibration and Testing: Regularly calibrate using manometers or digital gauges. Leak test with soapy water or helium detectors. For critical apps, use flow restrictors downstream.

- Maintenance: Inspect for corrosion quarterly. Replace diaphragms every 1-2 years. Store spares in clean, dry conditions.

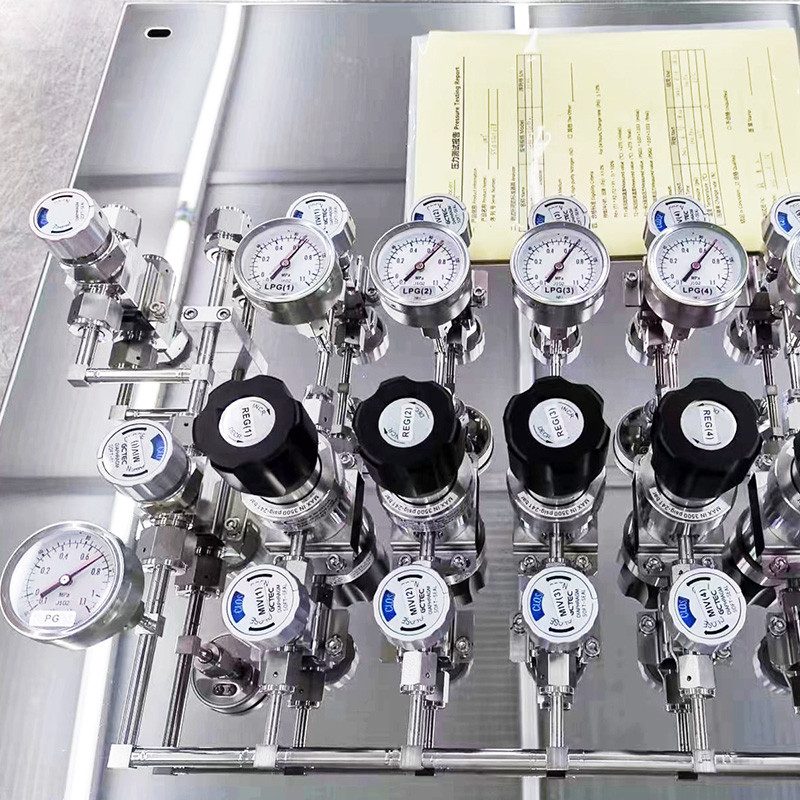

- Integration with Systems: In manifold setups for multiple cylinders, use automatic changeover regulators to switch seamlessly, ensuring uninterrupted supply.

Case Example: In a pharmaceutical lab using nitrogen for inerting, a single-stage regulator led to pressure fluctuations, causing inconsistent reaction yields. Switching to a two-stage model stabilized pressure, improving yield by 15%.

Another scenario: A university physics lab handling hydrogen for plasma experiments chose a piston-type regulator with flashback arrestors, preventing accidents during high-flow operations.

Advanced Considerations

For specialized labs:

– Ultra-High Purity (UHP) Regulators: Feature VCR fittings and helium leak rates < 10^-9 cc/sec. Essential for trace analysis.

– Point-of-Use Regulators: Installed near equipment for fine control, reducing line losses.

– Back-Pressure Regulators: Maintain upstream pressure, useful in venting systems.

Environmental factors: Labs in humid areas need corrosion-resistant coatings. Temperature compensation in regulators prevents pressure drift with ambient changes.

Future Trends: Smart regulators with IoT connectivity for remote monitoring and predictive maintenance are emerging, reducing human error.

Conclusion

Determining the best gas pressure regulator for laboratory use depends on specific needs, but two-stage, diaphragm-sensing models in stainless steel generally offer the optimal balance of precision, safety, and reliability. For high-purity or automated setups, electronic variants shine. Avoid compromising on compatibility or safety features, as they safeguard both experiments and personnel.

By evaluating pressure range, flow, gas type, and budget, labs can select regulators that enhance efficiency. Regular maintenance ensures longevity. Ultimately, investing in quality regulators minimizes risks and maximizes scientific output, making them indispensable tools in modern laboratories.

For more about which gas pressure regulator is best for laboratory use, you can pay a visit to Jewellok at https://www.jewellok.com/laboratory/ for more info.

Recent Posts

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

The Top High-Pressure Argon Gas Regulator Manufacturer in China

How to Choose a Gas Cylinder Manifold System

Tags

Recommended Products

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

High Purity High Pressure Gas Cylinder Pressure Regulators Pressure Reducing Valve JSR-1E Series

-

7121L Plug High Purity Plug Fitting And Blanking Plug

-

Line And Panel Mounting Adjustable Low Pressure Propane And Nitrogen Pressure Regulator JSR-3L & JSR-3LP Series

-

767LT Reducer Pressure Reducing Valve Adjustment High purity Pressure Reducing Union Fittings And Tubing

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems