Blog

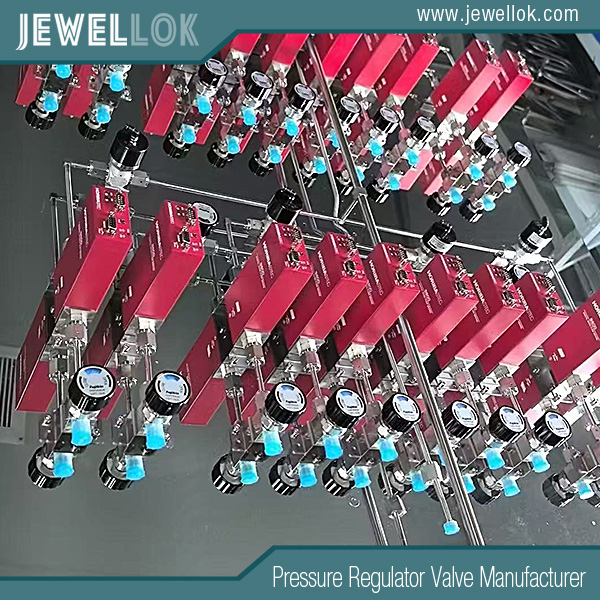

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What Are the Serious Consequences of A Damaged Diaphragm in A Propane Pressure Regulator Valve?

- Pressure Regulator Valve Manufacturer

- 1 1 2 gas pressure regulator, 1/2 gas pressure regulator, 1/2 Gas Pressure Regulator manufacturer, 2 electric valveadjustable propane pressure regulator, 3000PSI Nitrogen Panel Mount Pressure Regulator, 316L Stainless Steel Gas Pressure Regulators, 316l stainless steel pressure regulator, adjustable air pressure regulator, adjustable high pressure regulator, adjustable hydraulic pressure regulator, Adjustable Pressure Regulators, adjustable propane pressure regulator, air compressor pressure regulator, air pressure regulator diagram, air pressure regulator electronic control, Air pressure Regulator for Pneumatic, air pressure regulator valve with gauge, back pressure regulator valve, gas pressure regulator supplier, Gas Pressure Regulator Valve, Gas Pressure Regulator Valve Manufacturer, High Pressure Regulator Valve Manufacturer, How to adjust air pressure regulator valve, hydrogen pressure regulator valve, pressure regulator, Pressure Regulator Valve, pressure regulator valve leaking, Pressure Regulator Valve Manufacturer, pressure regulator valve manufacturers, pressure regulator valves manufacturer, pressure regulator valves supplier, propane pressure regulator valve, propane pressure regulator valve manufacturer, propane pressure regulator valve supplier, propane pressure regulator valves factory

- No Comments

What Are the Serious Consequences of A Damaged Diaphragm in A Propane Pressure Regulator Valve?

Propane pressure regulator valves are essential components in propane gas systems, commonly used in residential, commercial, and recreational applications such as heating, cooking, and powering RVs. These devices reduce the high pressure from propane storage tanks—typically around 100-200 psi—to a safer, usable level for appliances, usually in the range of 10-14 inches of water column (WC). At the heart of this regulation process is the diaphragm, a flexible membrane that senses and responds to pressure changes to maintain consistent output.

However, like any mechanical part, the diaphragm can degrade over time due to wear, environmental factors, or improper handling. When damaged, it can lead to various pressure anomalies that compromise system efficiency, safety, and performance. These anomalies manifest as irregular gas flow, which can result in appliance malfunctions, energy waste, or even hazardous situations like gas leaks. Understanding these issues is crucial for homeowners, technicians, and propane users to prevent accidents and ensure reliable operation.

This article delves into the specific pressure anomalies caused by a damaged diaphragm in a propane pressure regulator valve. We will explore the diaphragm’s function, common causes of damage, and the resulting pressure irregularities. Additionally, we will provide a detailed guide on using a manometer—a precise pressure-measuring tool—to detect whether the outlet pressure complies with manufacturer specifications. By the end, readers will have a comprehensive understanding of how to identify and address these problems, emphasizing safety and preventive maintenance. This knowledge is vital, as faulty regulators contribute to thousands of propane-related incidents annually, according to industry reports.

The Role of the Diaphragm in a Propane Pressure Regulator

To appreciate the impact of diaphragm damage, it’s essential to understand its function within the regulator. A propane pressure regulator valve typically consists of an inlet connected to the high-pressure tank, a valve mechanism, a spring, and the diaphragm. The diaphragm acts as a sensing element, separating the high-pressure side from the low-pressure outlet. It is usually made from durable elastomers like rubber or synthetic materials designed to flex under pressure variations.

When propane flows from the tank, it enters the regulator at high pressure. The diaphragm, backed by a spring, pushes against the valve to control the flow. If the outlet pressure drops (e.g., when an appliance is in use), the diaphragm relaxes, allowing more gas to enter and restore equilibrium. Conversely, if pressure builds up, the diaphragm compresses the spring, restricting flow. This dynamic adjustment ensures a steady output pressure, critical for safe appliance operation.

The diaphragm’s integrity is key to this balance. It must remain flexible yet airtight to prevent leaks and accurately respond to pressure changes. In standard low-pressure regulators for propane, the target outlet pressure is often set at 11 inches WC, equivalent to about 0.4 psi, which is ideal for most household appliances. Any compromise in the diaphragm’s structure can disrupt this delicate mechanism, leading to anomalies that affect the entire system.

Common Causes of Diaphragm Damage

Diaphragm damage doesn’t occur in isolation; it’s often the result of cumulative factors. Exposure to extreme temperatures can cause the material to crack or harden, reducing flexibility. For instance, in cold climates, propane regulators may experience freezing, where moisture condenses and expands, stressing the diaphragm. High heat from nearby engines or direct sunlight can degrade the elastomer over time.

Contaminants like dirt, debris, or chemical residues from impure propane can clog or abrade the diaphragm, leading to tears or holes. Over-pressurization, perhaps from a faulty tank valve or improper installation, can stretch the diaphragm beyond its limits, causing distortion or rupture. Mechanical wear from repeated cycling—common in high-usage scenarios like commercial kitchens—also contributes to fatigue.

Additionally, age is a factor; manufacturers recommend replacing regulators every 5-10 years, as diaphragms naturally deteriorate. Neglecting routine inspections exacerbates these issues, turning minor wear into significant damage. Recognizing these causes helps in preempting anomalies, but when damage occurs, specific pressure irregularities become evident.

Specific Pressure Anomalies from a Damaged Diaphragm

A damaged diaphragm disrupts the regulator’s ability to maintain consistent pressure, resulting in several distinct anomalies. These can be categorized based on their nature: over-pressure, under-pressure, fluctuations, and leaks.

- High Output Pressure (Over-Pressurization): If the diaphragm develops cracks or loses elasticity, it may fail to compress adequately against the spring, allowing excessive gas to flow through. This results in outlet pressure exceeding the specified range, often above 14 inches WC. Appliances may produce overly large flames, leading to inefficient burning, soot buildup, and potential fire hazards. In severe cases, this can damage appliance components designed for lower pressures.

- Low Output Pressure (Under-Pressurization): Conversely, a torn or stuck diaphragm might restrict gas flow excessively, causing pressure to drop below 10 inches WC. This manifests as weak or flickering flames, slow heating, or appliances failing to ignite. Users might notice frost on the regulator body due to rapid gas expansion and cooling, a telltale sign of sudden pressure drops.

- Pressure Fluctuations: Damage can cause erratic behavior, where pressure oscillates unpredictably. A warped diaphragm might respond sluggishly to demand changes, leading to surges and dips. This anomaly is particularly noticeable during peak usage, such as when multiple appliances operate simultaneously, resulting in inconsistent performance like varying flame heights or intermittent shutdowns.

- Gas Leaks and Pressure Loss: Holes or tears in the diaphragm can allow gas to escape internally or externally, causing gradual pressure loss. This often accompanies a propane odor, hissing sounds, or visible bubbles if soapy water is applied for testing. Leaks not only reduce outlet pressure but pose explosion risks, making them the most dangerous anomaly.

- Slow Response Time: A degraded diaphragm may not adjust quickly to pressure variations, leading to delayed stabilization. This can cause initial over-pressure spikes followed by drops, affecting sensitive appliances like water heaters or furnaces. These anomalies often interconnect; for example, a leak might exacerbate fluctuations. Symptoms extend beyond pressure readings to visual cues like yellow/orange flames (indicating incomplete combustion due to improper pressure) or soot accumulation. In RVs or portable systems, vibrations can accelerate damage, amplifying these issues.

The Importance of Detecting Pressure Anomalies

Ignoring these anomalies can lead to catastrophic failures. High pressure might overheat appliances, while low pressure causes inefficiency and carbon monoxide buildup. Leaks increase fire and explosion risks, with propane being heavier than air and prone to pooling in low areas. Regulatory bodies like the NFPA (National Fire Protection Association) mandate regular checks to comply with safety standards.

Early detection prevents costly repairs and ensures compliance with specifications, typically outlined in the regulator’s manual (e.g., 11 inches WC ±1 inch). Tools like manometers provide accurate, quantitative assessments, surpassing subjective observations.

Introduction to Manometers for Pressure Testing

A manometer is a simple yet precise instrument for measuring gas pressure, often using a U-shaped tube filled with water or mercury. For propane systems, water-filled manometers are preferred due to safety and ease. They measure pressure in inches WC, directly relevant to low-pressure gas applications. Digital manometers offer greater accuracy and readability, but analog versions suffice for most users. Essential features include a scale from 0-20 inches WC, flexible tubing for connections, and a stable base. Always use a manometer rated for gas pressures to avoid inaccuracies.

Step-by-Step Guide: Using a Manometer to Check Outlet Pressure

Testing the outlet pressure of a propane pressure regulator valve with a manometer is a straightforward process, but safety is paramount. Work in well-ventilated areas, avoid open flames, and shut off the gas supply before starting. Here’s a detailed guide:

- Gather Tools and Prepare: You’ll need a manometer, flexible tubing (1/4-inch diameter), a wrench, and the regulator’s specifications (usually 10-14 inches WC for propane). Ensure the manometer is calibrated—zero it by ensuring both legs are level when disconnected. Locate the regulator’s test port, often a plugged outlet on the low-pressure side.

- Shut Off the System: Turn off the propane tank valve and all appliances. Depressurize the system by opening a stove burner briefly to release residual gas.

- Connect the Manometer: Remove the test port plug using a wrench (typically 1/8-inch NPT). Attach one end of the tubing to the manometer’s positive port and the other to the test port. For U-tube manometers, connect to the input side; the output side remains open. Hold or mount the manometer vertically for accurate readings.

- Turn On the Gas Supply: Slowly open the tank valve. The pressure will push the water column down on the input side and up on the output side. Read the difference between the two levels—this is the static outlet pressure.

- Test Under Load: For a comprehensive check, operate appliances to simulate demand. Start with one, then add more, monitoring for pressure drops. The pressure should remain stable within specs (e.g., no more than a 1-inch WC drop under full load).

- Record and Compare Readings: Note the pressure at rest and under load. Compare to the manufacturer’s specs—if it’s outside the range (e.g., below 10 or above 14 inches WC), the regulator may be faulty, possibly due to diaphragm damage.

- Disconnect and Inspect: Shut off the gas, remove the tubing, and replace the plug. Check for leaks using soapy water.

If readings indicate non-compliance, do not attempt repairs—replace the regulator, as diaphragms are not user-serviceable. Professional assistance is recommended for complex systems.

Interpreting Results and Next Steps

Compliant pressures confirm a healthy diaphragm and regulator. Anomalies like persistent low pressure suggest damage, warranting replacement. Document tests for maintenance records. If anomalies persist post-replacement, check upstream issues like tank levels or line blockages.

Regular testing—annually or after incidents—prevents escalation. Combine with visual inspections for cracks or frost.

Conclusion

A damaged diaphragm in a propane pressure regulator can cause critical anomalies like high/low pressure, fluctuations, and leaks, endangering safety and efficiency. Using a manometer provides an accurate way to verify outlet pressure compliance, empowering users to act proactively.

Prioritize safety: Never ignore gas odors or irregular flames—evacuate and call professionals. With proper maintenance, propane systems remain reliable. This article, drawing from technical insights, underscores the value of vigilance in gas handling.

For more about what are the serious consequences of a damaged diaphragm in a propane pressure regulator valve, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

767LP Port Connector Ultra High Purity VCR Metal Gasket Face Seal Tube Fittings

-

Scrubber Tail Gas Treatment Cabinet Waste Gas Treatment Wet Scrubber Exhaust Gas Treatment Spray Tower

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve

-

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

Pressure Control Panels For High Purity Gas Control System JSP-3AE Series From Pressure Control Panels Suppliers And Manufacturer

-

739LF High Purity Female Adapter Tube To Pipe Fittings And Connectors

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings