Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does a Single-Stage Oxygen Regulator Work?

- Pressure Regulator Valve Manufacturer

- back pressure regulator manufacturers, china high pressure air regulator valve manufacturer, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, gas regulator valve manufacturers, High Flow Oxygen Regulator, high pressure ball valve manufacturer, High Pressure Gauge for Oxygen Regulator 0-4000 psi, High Pressure Oxygen Regulator, high purity valves manufacturers, High Volume High Pressure Oxygen Regulators, High Volume Oxygen Regulators, Low and High Pressure Gauges for Oxygen Regulator, low pressure oxygen regulator, low pressure valve manufacturer, medical oxygen pressure gauge manufacturer, Medical Oxygen Regulator, medical oxygen regulator manufacturer, Medical Oxygen Regulatorpressure reducing valve manufacturers in india, oxygen regulator, oxygen regulator gauge, oxygen regulator gaugegas manifold system, pressure gauge manufacturers, pressure reducing valve manufacturers, pressure relief valve manufacturers, seema oxygen regulator, single gauge oxygen regulator, single oxygen regulator, single stage double gauge oxygen regulator, Single Stage High Pressure Oxygen Regulator, single stage oxygen regulator, single-stage oxygen regulator manufacturer, single-stage oxygen regulator supplier, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer

- No Comments

How Does a Single-Stage Oxygen Regulator Work?

In the worlds of medicine, metalworking, aerospace, and emergency response, oxygen is a lifeline. Yet, the oxygen stored in high-pressure cylinders—often at a staggering 2,200 pounds per square inch (psi) or more—is far too powerful and dangerous to use directly. Delivering this vital gas safely and controllably to a patient’s mask, a welder’s torch, or a laboratory instrument requires a critical piece of engineering: the pressure regulator. Among these, the single-stage oxygen regulator stands as the most common, reliable, and cost-effective workhorse. This article delves into the inner workings of this indispensable device, exploring its components, its precise mechanical ballet, and its pivotal role in taming raw pressure for human use.

The Fundamental Challenge: From Bottled Force to Controlled Flow

An industrial or medical oxygen cylinder is a reservoir of immense potential energy. Its contents are compressed to pressures that can range from 1,800 psi for a small “E” cylinder to over 3,000 psi for larger industrial tanks. In stark contrast, the required working pressures are minuscule:

- Medical Oxygen: Typically delivered at 50 psi or less to hospital wall outlets, or directly to a mask at just a few psi.

- Oxy-Fuel Welding & Cutting: Requires precise control, often between 5 psi for delicate brazing and 30-40 psi for cutting thick steel.

Bridging this colossal gap is the regulator’s sole purpose. It must reduce the high, variable cylinder pressure to a lower, stable, and user-adjustable working pressure. The single-stage regulator accomplishes this in one continuous, self-contained operation. Its design is an elegant solution to a problem of force balance, relying on simple principles of physics to ensure safety and precision.

Anatomy of a Single-Stage oxygen Regulator: Key Components

To understand how it works, we must first familiarize ourselves with its internal parts. A typical single-stage regulator consists of two main chambers separated by a critical sensing element.

- The High-Pressure Section (Inlet Side):

- Inlet Connection: Features a specific Compressed Gas Association (CGA) fitting—CGA 540 for oxygen in the U.S.—to prevent accidental connection to the wrong gas cylinder. This is a crucial safety feature.

- High-Pressure Gauge: Measures the pressure remaining in the cylinder (in psi or bar). This gauge reads the inlet pressure, which will steadily decline as the cylinder empties.

- Filter Screen: A small mesh screen that traps particulate debris from the cylinder, protecting the delicate internal valve seats.

- Inlet Valve Seat: A precisely machined opening where gas enters the regulating mechanism.

- The Sensing and Control Assembly (The “Brain”):

- Diaphragm: The heart of the regulator. This is a flexible, typically rubber or polymer-coated disk that acts as a pressure sensor and the primary moving wall. It responds to minute changes in downstream pressure.

- Control Spring: A large, helical spring that sits atop the diaphragm, applying a downward force. The user directly compresses this spring via the adjusting knob.

- Adjusting Knob/Screw: The user interface. Turning it clockwise compresses the control spring, increasing the downstream pressure setting. Turning it counter-clockwise de-compresses the spring, decreasing pressure. It should always be fully turned out (de-tensioned) when opening the cylinder valve.

- Valve Stem & Poppet Assembly: Connected to the center of the diaphragm. The poppet, often tipped with a resilient material like Neoprene or Teflon®, forms a seal against the inlet valve seat.

- The Low-Pressure Section (Outlet Side):

- Low-Pressure Chamber: The space where the reduced, controlled pressure is held.

- Low-Pressure (Delivery) Gauge: Indicates the working pressure set by the user and being supplied to the hose or apparatus.

- Outlet Port: The connection point for the delivery hose, which leads to the torch, mask, or other device.

The Operational Cycle: A Delicate Balance of Forces

The operation of a single-stage regulator is a continuous, automatic feedback loop. It can be understood in three primary states:

State 1: At Rest (Cylinder Valve Closed, Adjusting Knob Out)

- The control spring is relaxed, applying minimal force.

- The diaphragm is in its neutral position.

- The valve stem and poppet are forced by a small internal spring (or the diaphragm’s own tension) firmly onto the inlet seat, creating a tight seal. No gas flows.

State 2: Setting the Pressure (Cylinder Valve Open, Adjusting Knob Turned)

- The cylinder valve is opened slowly. High-pressure oxygen fills the inlet chamber and pushes against the back of the poppet, but the poppet seal holds.

- The user turns the adjusting knob clockwise. This compresses the control spring, which pushes down on the diaphragm.

- The diaphragm bows downward, pushing the valve stem and poppet away from the inlet seat.

- A controlled gap opens. High-pressure gas rushes through this gap from the high-pressure chamber into the low-pressure chamber.

- As gas fills the low-pressure chamber, pressure builds. This increasing pressure acts on the underside of the diaphragm, pushing it upward.

- The diaphragm rises until the upward force from the low-pressure gas exactly balances the downward force from the control spring. At this equilibrium point, the diaphragm positions the poppet to partially close the inlet gap, allowing just enough gas flow to maintain the set pressure. The system is now in active regulation.

State 3: Responding to Demand (Tool in Use)

- When the torch or medical device is turned on, gas flows out of the low-pressure chamber, causing a momentary pressure drop.

- This drop reduces the upward force on the diaphragm.

- The now-stronger downward force from the control spring pushes the diaphragm down again, opening the inlet valve wider.

- Increased gas flow enters the low-pressure chamber to restore the set pressure.

- When the tool is turned off, pressure builds slightly, pushing the diaphragm up to close the valve further.

- This dynamic, continuous adjustment happens in real-time, maintaining a remarkably stable output pressure despite fluctuating demand.

The Inherent Characteristic: “Droop” or “Creep”

The single-stage design has one fundamental behavioral trait that defines its application. As the cylinder empties, the inlet pressure (shown on the high-pressure gauge) falls. Because the regulating mechanism relies on the balance between spring force and outlet pressure, the decreasing inlet pressure subtly affects the valve’s equilibrium.

- Droop (Fall-Off): As the cylinder pressure drops, the force pushing the poppet closed weakens slightly. To maintain balance, the diaphragm adjusts, allowing the poppet to open a tiny bit more. This can cause a very gradual decrease in delivery pressure over the life of the cylinder. For example, a regulator set at 25 psi with a full tank may deliver 23 psi when the tank is near empty.

- Why it Matters: This “droop” is usually insignificant for short-duration tasks like welding a single joint or for applications with a wide acceptable pressure range. However, for long, continuous processes requiring extreme precision, this characteristic is the primary reason to choose a more complex (and expensive) two-stage regulator, which minimizes droop.

Critical Safety Features and Considerations

Working with high-pressure oxygen demands rigorous safety protocols, and the regulator is engineered with this in mind.

- Oxygen-Specific Cleaning: “Oxygen service” regulators are manufactured, cleaned, and assembled in a contaminant-free environment. Even tiny amounts of oil or hydrocarbon grease can spontaneously ignite in the presence of high-pressure oxygen, causing a violent explosion. This is why the rule “Never use oil on oxygen equipment!” is paramount.

- Materials Compatibility: All wetted parts (those in contact with oxygen) must be made of compatible, non-combustible materials like brass, stainless steel, Monel, or Teflon®. Seals are typically made of Viton® or other oxygen-safe elastomers.

- Pressure Relief Devices: Many regulators include a burst disk or fusible plug on the low-pressure side. If the regulator fails internally and the downstream pressure rises dangerously (e.g., due to a stuck valve or heat from a flashback), this device will rupture, safely venting pressure and preventing a catastrophic hose or apparatus failure.

- CGA Connections: The specific, non-interchangeable inlet threads prevent the connection of an oxygen regulator to, say, an acetylene or hydrogen cylinder, averting a potentially deadly mix-up.

Applications: Where the Single-Stage Regulator Shines

The single-stage oxygen regulator is the perfect balance of simplicity, affordability, and reliability for a vast array of uses:

- Oxy-Fuel Welding, Cutting, and Brazing: The quintessential application. Welders rely on its straightforward adjustment to set precise flame characteristics.

- Medical Oxygen Delivery: In ambulances, clinics, and for home healthcare, these regulators provide a steady flow from portable cylinders to patient masks, nasal cannulas, or ventilators.

- Laboratory & Research: Used to supply oxygen for gas chromatographs, reactors, or controlled atmosphere experiments.

- Aquaculture & Water Treatment: To regulate oxygen fed into fish ponds or water purification systems.

- Glassworking: For fueling torches used in glassblowing and lampworking.

- Emergency & Rescue: In SCBA (Self-Contained Breathing Apparatus) systems for firefighters and in aviation emergency systems.

Selection, Use, and Maintenance Best Practices

- Selection: Choose the correct CGA fitting for your cylinder and country. Ensure the pressure ranges (both inlet max and outlet adjustable) suit your application. For high-purity medical use, select units certified for that purpose.

- Safe Operation:

- Always “crack” the cylinder valve (open and close it momentarily) before attaching the regulator to clear any dust from the port.

- Stand to the side of the gauges when opening the main cylinder valve.

- Open the cylinder valve slowly and fully to seat the valve properly.

- Always turn the adjusting knob out fully before opening the cylinder valve, and turn it out to release pressure before closing the cylinder.

- Maintenance: Regularly inspect for damage or leaks using a leak detection solution (soapy water). Never use the regulator as a handle to move cylinders. Have it inspected and serviced by qualified technicians at intervals recommended by the manufacturer.

Conclusion

The single-stage oxygen regulator is a testament to elegant, functional engineering. It transforms an uncontrollable, stored force into a safe, precise, and obedient tool. By harnessing the simple physics of a spring-balanced diaphragm, it performs the vital, continuous duty of moderation. While it may exhibit the characteristic droop that defines its single-stage nature, its reliability, cost-effectiveness, and robustness make it the undisputed cornerstone of oxygen delivery across countless fields. From the life-saving breath it delivers to a patient to the brilliant flare of a welding arc, the single-stage regulator works silently and ceaselessly in the background—a fundamental gatekeeper that makes the modern use of oxygen not just possible, but safe and profoundly practical.

For more about how does a single-stage oxygen regulator work, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

Tags

Recommended Products

-

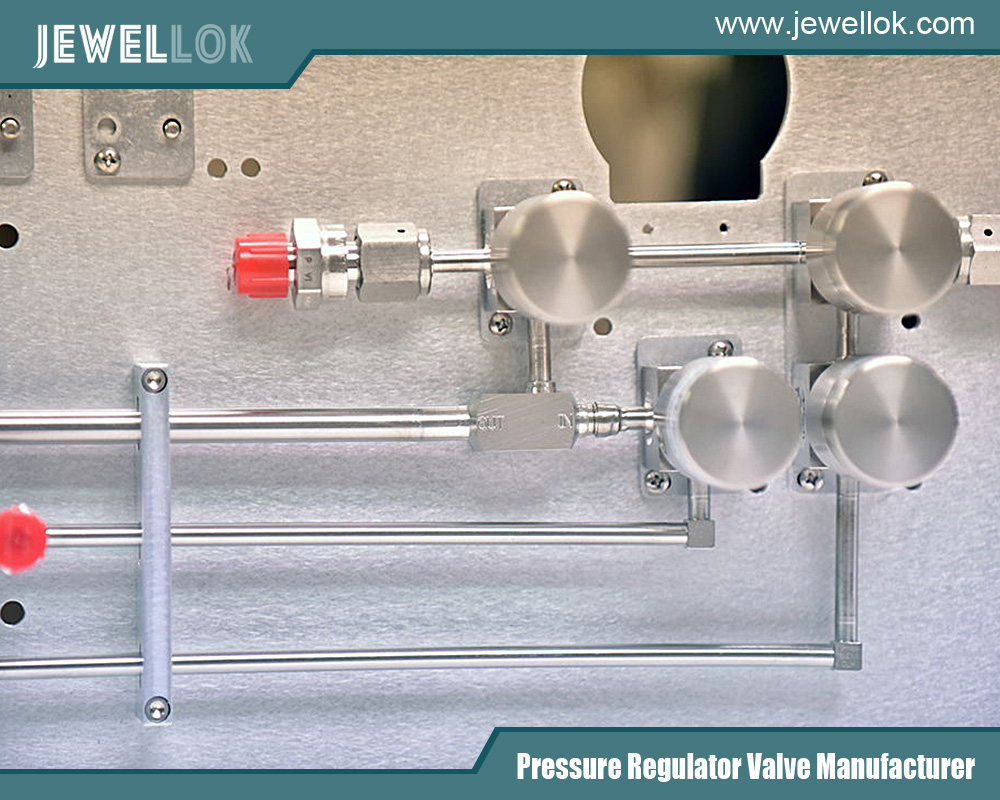

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

Specialty Gas Valves Ultra High Purity Gas Valves Ultra High Purity Gas Cylinder Valves UHP Cylinder Valve Ultra High Purity Gas Regulator

-

768LN Stainless Steel Male Pipe Tube Butt Weld Connector And Tube Fittings Supplier

-

772 LF Female Branch Tee | Stainless Steel Tube Fitting Female Branch Tee 1/2 in. Tube OD x 1/2 in. Tube OD x 3/8 in. Female NPT

-

High Purity Chemical Dispense System & Packing System For Semiconductors JW-200L-CDM & JW-1000L-CDM

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process