Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Best Top 10 Gas Manifold System Manufacturers in India

- Pressure Regulator Valve Manufacturer

- argon gas manifold system, Best gas manifold system manufacturers, Best Gas Manifold System Manufacturers in Delhi, Best Gas Manifold System Manufacturers in India, compressed gas manifold systems, gas manifold system, gas manifold system in hospital, Gas Manifold System Manufacturer from Coimbatore, Gas Manifold System Manufacturer from Delhi, Gas Manifold System Manufacturer from Jaipur, Gas Manifold System Manufacturer from Pune, Gas manifold system manufacturers, gas manifold system manufacturers in india, Gas manifold systems and tapping points, Gas manifold systems with automatic switch-over, High Pressure Nitrogen Gas Manifold System, High-purity gas manifold system, Industrial Gas Manifold Systems

- No Comments

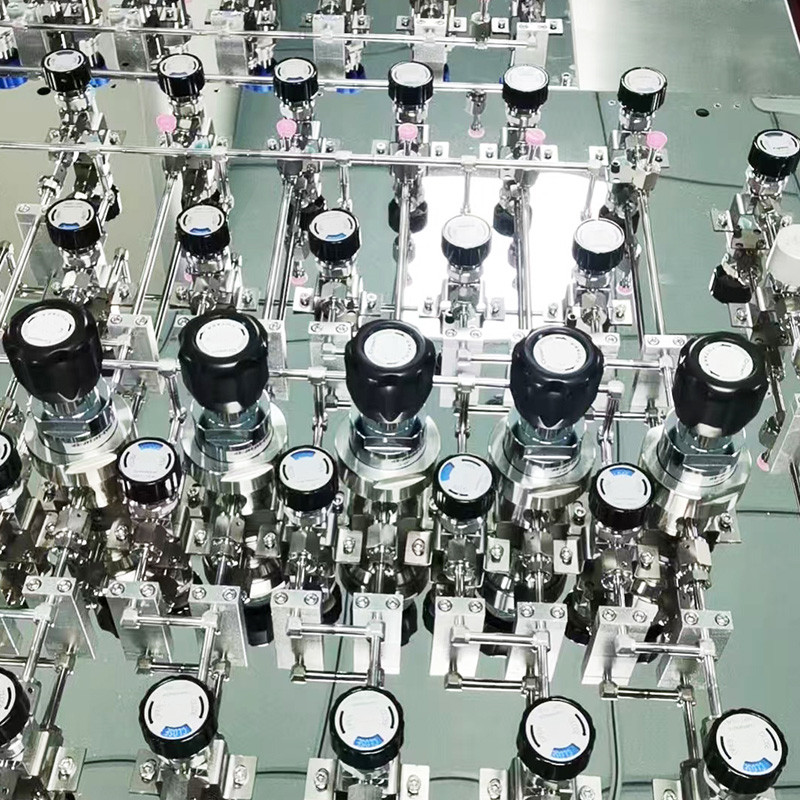

Best Top 10 Gas Manifold System Manufacturers in India

Introduction

Gas manifold systems play a critical role in the safe and efficient distribution of gases across various industries, including healthcare, manufacturing, petrochemicals, and research laboratories. These systems are designed to connect multiple gas cylinders to a single outlet, ensuring continuous supply, pressure regulation, and safety through features like automatic changeover, leak detection, and high-pressure resistance. In India, the demand for gas manifold systems has surged due to rapid industrialization, expanding healthcare infrastructure, and the push towards cleaner energy sources like LPG and compressed natural gas (CNG). The market is projected to grow at a compound annual growth rate (CAGR) of over 8% in the coming years, driven by government initiatives such as the Pradhan Mantri Ujjwala Yojana for LPG distribution and the emphasis on medical oxygen systems post-pandemic.

Selecting the best manufacturers involves evaluating factors like product quality, innovation, certifications (e.g., ISO 9001, CE), market reputation, customization capabilities, and after-sales support. This article highlights the top 10 gas manifold system manufacturers in India, based on their contributions to the sector, technological advancements, and customer satisfaction. Each company is profiled with insights into their history, key products, technical specifications, and unique strengths, providing a comprehensive overview for industry professionals, buyers, and stakeholders.

1. OXYVAC India Works

OXYVAC India Works, established in 2017, has quickly emerged as a leader in gas manifold solutions, specializing in design, engineering, and erection services for gas-related industries. Headquartered in India, the company focuses on high-pressure systems that cater to industrial and medical applications. Their manifolds are engineered for seamless integration into existing pipelines, ensuring minimal downtime during installation.

Key products include oxygen and nitrogen manifolds with capacities ranging from 2 to 20 cylinders, featuring automatic changeover regulators that maintain pressure between 4-10 bar. These systems incorporate safety valves rated for pressures up to 300 bar and are constructed from corrosion-resistant stainless steel (SS316 grade) to withstand harsh environments. OXYVAC’s hydrotesting equipment complements their manifolds, allowing for on-site pressure testing up to 500 bar.

Technically, their gas filling panels use advanced flow meters with accuracy of ±1% and digital pressure gauges for real-time monitoring. Innovations include IoT-enabled safety systems that alert users to leaks via mobile apps. Certified under ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018, OXYVAC emphasizes quality through in-house laboratories. Their manifolds have been deployed in over 100 projects, reducing gas wastage by 15-20% through efficient design.

2. Plumberstar

Founded in 2006, Plumberstar is a global player with a strong presence in India, manufacturing valves, fittings, and manifolds for residential and industrial gas distribution. As an OEM specialist, they offer customized solutions, making them ideal for large-scale projects. Their Indian operations focus on brass and stainless steel manifolds that comply with international standards.

Plumberstar’s gas manifolds come in modular designs with 4-12 ports, supporting gases like LPG, natural gas, and hydrogen. Technical features include pressure ratings of 150-250 psi, with ball valves for precise flow control and PEX connections for flexibility. Their plastic manifolds are lightweight, reducing installation costs by 30%, and feature UV-resistant coatings for outdoor use.

Innovation highlights include smart manifolds with embedded sensors for temperature and pressure monitoring, integrated with building management systems. Holding certifications like BSCI, CSA, cUPC, and ISO 9001, Plumberstar ensures products undergo rigorous testing, including burst tests at 500 psi. Their customer-centric approach includes free inspection reports, positioning them as a reliable choice for energy-efficient gas systems in India’s growing urban infrastructure.

3. AXCEL Gases

AXCEL Gases, started in 2007, is renowned for its expertise in gas generation and distribution equipment, exporting to over 20 countries. In India, they manufacture manifold systems for high-purity gases used in pharmaceuticals and electronics. Their systems are designed for reliability, with minimal maintenance requirements.

Products include nitrogen evaporators and hydrogen manifold systems with capacities up to 50 cylinders, operating at pressures of 200-400 bar. Constructed from alloy steel, these manifolds feature dual-line configurations for redundancy, ensuring uninterrupted supply. Regulators provide flow rates of 10-100 Nm³/h with purity levels exceeding 99.999%.

AXCEL’s technical edge lies in customized hydrogen generators integrated with manifolds, using electrolysis for on-site production. Safety features include explosion-proof enclosures and automatic shut-off valves. ISO 9001:2008 certified, they conduct in-house inspections to meet global standards. Their manifolds have improved efficiency in Indian refineries by optimizing gas flow, reducing operational costs by 10-15%.

4. Gas Control Equipment India Pvt Ltd

Established in 2011 as a subsidiary of the European GCE Group, Gas Control Equipment India Pvt Ltd brings international expertise to the Indian market. Based in Bangalore, they produce manifolds for cutting, welding, medical, and high-purity applications, serving diverse sectors.

Their manifolds support oxygen, acetylene, and argon, with models featuring 6-16 cylinder connections and pressure regulators adjustable from 0.5-20 bar. Materials like chrome-plated brass ensure durability, with flow capacities up to 200 l/min. Advanced features include flashback arrestors and non-return valves for enhanced safety.

Technically, their process application manifolds use PLC controls for automated changeover, minimizing human error. With a workforce of over 870 globally, they innovate through R&D, introducing eco-friendly designs that reduce emissions. Certifications include CE and ATEX for hazardous areas. In India, their systems are widely used in automotive manufacturing, improving productivity through stable gas supply.

5. Mediline Engineers Private Limited

Mediline Engineers Private Limited, founded in 2020, specializes in medical gas manifold systems, addressing the healthcare sector’s needs. Under experienced leadership, they prioritize customization and timely delivery, exporting to international markets.

Key offerings include oxygen control panels and hospital manifolds with 2-10 cylinder setups, designed for pressures up to 150 bar. Made from medical-grade copper and stainless steel, these systems include alarms for low pressure and integrate with central monitoring units. Flow rates are calibrated to 15-50 l/min per outlet.

Innovations feature seamless finishes and automated valves that switch cylinders without interruption, critical for ICUs. Products are affordable yet high-quality, with ISO compliance ensuring sterility. Mediline’s manifolds have been instrumental in equipping over 50 hospitals in India, enhancing patient safety through reliable oxygen delivery.

6. Chemix Specialty Gases and Equipment

Chemix, established in 2015 in Bangalore, excels in high-pressure regulators and manifolds for laboratory and specialty gas applications. They manufacture systems for precise control in research and pharma industries.

Their manifolds handle gases like helium and CO2, with configurations for 4-8 cylinders and pressure ratings of 100-300 bar. Single-stage and two-stage regulators provide accuracy of ±0.5%, with materials resistant to corrosive gases.

Technical advancements include specialty regulators with fine-thread adjustments for micro-flow control. Chemix’s focus on innovation supports scientific progress, with systems used in over 200 labs. Their quality assurance processes ensure reliability, making them a top choice for high-purity needs.

7. ABB India

ABB India, a subsidiary of the global ABB Group, manufactures integrated gas analyzer systems that include manifolds for real-time monitoring in oil and gas sectors. Headquartered in Bengaluru, they export extensively.

Manifolds are part of analyzer packages, handling multiple gases with pressures up to 250 bar and flow rates of 50-500 l/min. Stainless steel construction and digital interfaces allow integration with SCADA systems.

Innovations include customized fabrication with engineering support, earning awards for excellence. ABB’s systems optimize industrial processes, reducing downtime in Indian refineries.

8. Indian Compressors Ltd

Indian Compressors Ltd specializes in gas compressors and manifolds for transportation and distribution. Led by industry experts, they focus on sustainable solutions like hydrogen manifolds.

Products include diaphragm compressors with manifold integrations for pressures exceeding 400 bar, suitable for CNG and biogas.

Their technical designs emphasize efficiency, with low-vibration operations and global partnerships enhancing reliability.

9. Samphire Engineering & Equipments

Samphire offers manifolds for oxygen, argon, and CO2, with cylinder capacities up to 20 and pressures of 200 bar. Features include robust construction and easy maintenance.

Innovations in CO2 systems cater to beverage industries, improving carbonation processes.

10. Messer Cutting Systems India

Messer provides industrial gas manifolds for workshops and factories, with distribution systems for oxyfuel applications.

Manifolds support high-flow rates, with safety-focused designs certified for international standards.

Conclusion

India’s gas manifold manufacturers are at the forefront of technological advancements, supporting key sectors with reliable, innovative solutions. As the nation moves towards green energy, these companies will play a pivotal role in hydrogen and CNG adoption. Buyers should consider specific needs like pressure requirements and certifications when selecting a manufacturer. The future looks promising with increased R&D and exports, solidifying India’s position in global gas technology.

For more about best top 10 gas manifold system manufacturers in india, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-changeover-manifold/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

766L High Purity Female Connector UHP Fitting Female Connector

-

Medical Oxygen Single Stage Manual Gas Changeover Manifold Panel High-Purity Two-Stage Manual Gas Manifold Gas Pressure Control Panels

-

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB

-

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

-

Line And Panel Mounting Adjustable Low Pressure Propane And Nitrogen Pressure Regulator JSR-3L & JSR-3LP Series

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve