Blog

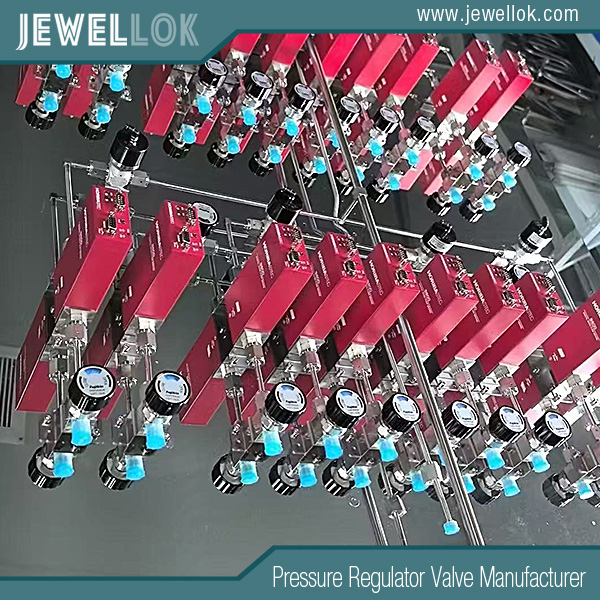

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

China High Pressure Needle Valve Manufacturer Tells You How To Select A Needle Valve

- Pressure Regulator Valve Manufacturer

- check valve manufacturers in china, china high pressure needle valve manufacturer, China High Pressure Needle Valve Suppliers, China Needle Valve Factory, china needle valve manufacturer, China Needle Valve Manufacturers, china stainless steel high pressure needle valve, china stainless steel high pressure needle valve manufacturer, China Top 10 High Pressure Needle Valve, high pressure 6000psi needle valve, High Pressure and High Temperature Stainless Steel Needle Valve, High Pressure Needle Valves, High Pressure Needle Valves China, High Pressure Needle Valves Manufacturer, pressure gauge manufacturers in china, Stainless Steel Needle Valve factory, top 10 valve manufacturers in china, valve manufacturers in china

- No Comments

China High Pressure Needle Valve Manufacturer Tells You How To Select A Needle Valve

In the intricate world of fluid control systems, precision is not just a luxury—it’s a necessity. Whether you’re managing the flow of hydraulic fluid in heavy machinery or fine-tuning pressure in a laboratory setting, the right valve can be the difference between seamless operation and catastrophic failure. Among the myriad of valve types, the needle valve stands out for its ability to provide exacting control, especially in high-pressure environments.

As a leading high-pressure needle valve manufacturer based in China, we understand the critical role these valves play in your operations. With years of experience and a commitment to innovation, we’re here to guide you through the process of selecting the perfect needle valve for your needs. In this comprehensive 2000-word guide, we’ll explore what needle valves are, why they’re essential in high-pressure applications, and how to choose the right one for your system.

What is a Needle Valve?

A needle valve is a precision-engineered device designed for fine flow control. Its defining feature is a long, tapered stem—resembling a needle—that fits into a conical seat. By turning the handle, the stem moves in or out of the seat, allowing for minute adjustments to the flow rate. This design makes needle valves ideal for applications requiring precise regulation, such as instrumentation, hydraulic systems, and high-pressure gas lines.

Unlike globe valves, which offer good throttling but less precision, needle valves excel in low-flow, high-pressure scenarios due to their unique stem and seat configuration. Their ability to provide gradual flow adjustments sets them apart, making them indispensable in industries where accuracy is paramount.

The Importance of High-Pressure Needle Valves

High-pressure needle valves are built to withstand extreme conditions, with pressure ratings typically starting at 10,000 psi (689 bar) and reaching up to 60,000 psi (4,136 bar) for specialized applications. These robust valves are critical in a variety of industries:

Oil and Gas: Controlling flow in pipelines and during extraction processes.

Aerospace: Regulating fuel systems where precision and reliability are non-negotiable.

Chemical Processing: Managing reactive or corrosive fluids under high pressure.

Power Generation: Regulating high-pressure steam or water in turbines.

Laboratories: Providing precise control in gas chromatography and analytical instruments.

In these high-stakes environments, selecting the right needle valve is essential to ensure safety, efficiency, and system longevity. A poorly chosen valve can lead to leaks, pressure drops, or even catastrophic failures, underscoring the importance of informed decision-making.

Key Factors in Selecting a High-Pressure Needle Valve

Choosing the right needle valve for a high-pressure application requires careful consideration of several factors. Below, we outline the key elements to evaluate:

1. Material Selection

The material of the valve is a cornerstone of its performance, particularly in high-pressure systems where strength and durability are critical. Common materials include:

Stainless Steel: Grades like 316 stainless steel are widely used for their excellent corrosion resistance and mechanical strength. They’re suitable for fluids such as water, oil, and many chemicals.

Brass: A cost-effective option for lower-pressure systems, but its lower strength makes it unsuitable for most high-pressure applications.

Exotic Alloys: For extreme pressures or corrosive environments, materials like Hastelloy, Inconel, or titanium offer superior strength and resistance, albeit at a higher cost.

When selecting a material, consider:

Fluid Compatibility: Ensure the material won’t react with the fluid to avoid corrosion or degradation. For example, stainless steel works well with many corrosive fluids, but some chemicals may require specialized alloys.

Temperature: High temperatures can reduce material strength. Verify the material’s temperature rating aligns with your system’s conditions.

Pressure: Higher pressures demand stronger materials. Valves for 60,000 psi applications often rely on exotic alloys for reliability.

Internal components like the stem and seat should also be made of compatible materials to ensure consistent performance and longevity.

2. Pressure Rating

The pressure rating defines the maximum pressure a valve can safely handle. For high-pressure systems, select a valve with a rating that exceeds your system’s maximum operating pressure, including any potential spikes. For example:

A system operating at 12,000 psi should use a valve rated for at least 15,000 psi as a safety margin.

Valves for ultra-high-pressure applications (e.g., 60,000 psi) require specialized designs and materials.

Look for valves tested to industry standards, such as those from the American Petroleum Institute (API) or the American Society of Mechanical Engineers (ASME), to ensure reliability under pressure.

3. Temperature Range

High-pressure systems often involve extreme temperatures, from cryogenic lows to scorching highs. The valve’s temperature rating must encompass your system’s full range, including any temporary excursions. For instance:

In chemical processing, temperatures might exceed 500°F (260°C), requiring materials and seals that maintain integrity.

In cryogenic applications, such as liquid nitrogen handling, valves must function at temperatures as low as -320°F (-196°C).

Ensure the valve’s seals and packing materials are also rated for these conditions to prevent leaks or failures.

4. Connection Types

Needle valves come with various connection options, each suited to specific piping systems:

NPT (National Pipe Thread): Prevalent in North America, offering a reliable seal for many applications.

BSP (British Standard Pipe): Common in Europe and Asia, ensuring compatibility in international systems.

Tube Fittings: Ideal for instrumentation, providing a leak-tight seal in high-pressure setups.

Verify that the valve’s connection type matches your system’s piping to avoid installation issues or leaks.

5. Flow Coefficient (Cv)

The flow coefficient (Cv) measures a valve’s capacity to flow fluid, critical for ensuring it meets your system’s flow requirements. Calculate Cv using the formula:

Cv=Q×SGΔP\text{Cv} = Q \times \sqrt{\frac{\text{SG}}{\Delta P}}\text{Cv} = Q \times \sqrt{\frac{\text{SG}}{\Delta P}}

Where:

( Q ) = Flow rate in gallons per minute (GPM)

SG= Specific gravity of the fluid

ΔP= Pressure drop across the valve in psi

For example, if you need a flow rate of 10 GPM with a specific gravity of 1 and a pressure drop of 25 psi, the required Cv is approximately 2. Select a valve with a Cv that aligns with or slightly exceeds this value.

6. Stem Design and Packing

Stem Design: A non-rotating stem reduces wear on the packing and seat, enhancing durability—especially important in high-pressure systems with frequent adjustments.

Packing Material: The packing seals the stem to prevent leaks. Common options include PTFE (for chemical resistance) and graphite (for high temperatures). Ensure compatibility with your fluid and operating conditions.

7. Industry Standards and Certifications

Opt for valves that meet recognized standards, such as:

ISO 9001: Ensures quality management in manufacturing.

API 6A: Relevant for oil and gas applications.

CE Marking: Indicates compliance with European safety standards.

Certifications from these bodies provide assurance of quality and performance, critical for high-pressure applications.

Advantages of Chinese High-Pressure Needle Valve Manufacturers

Chinese manufacturers have emerged as key players in the global valve market, offering distinct benefits:

Competitive Pricing: Lower labor and production costs allow Chinese valves to be more affordable without sacrificing quality.

Innovation and Technology: Many Chinese firms invest in R&D, developing features like advanced sealing technologies and precision-machined components.

Quality Control: Reputable manufacturers adhere to strict quality processes, often certified to ISO 9001 or similar standards, and may offer third-party testing.

Customization: Flexibility to tailor valves to specific needs is a hallmark of Chinese manufacturing, ideal for unique applications.

Global Reach: With a focus on exports, Chinese valves meet international standards, making them suitable for worldwide use.

By choosing a Chinese manufacturer, you gain access to high-quality, innovative valves at competitive prices, supported by robust quality assurance.

How to Choose the Right Needle Valve for Your Application

Selecting the perfect needle valve requires a structured approach:

Assess Your System’s Requirements

Identify maximum pressure and potential spikes.

Determine the temperature range.

Analyze the fluid’s chemical properties for compatibility.

Calculate the required flow rate and Cv.

Evaluate Valve Specifications

Confirm pressure and temperature ratings exceed system demands.

Ensure material suitability for fluid and conditions.

Match connection type to your piping.

Consider Additional Features

Non-rotating stems for durability.

Blow-out proof designs for safety.

Easy-maintenance options to reduce downtime.

Consult with Manufacturers

Discuss your application with technical experts.

Request data sheets, test reports, and certifications.

Explore warranty and support options.

Assess Total Cost of Ownership

Factor in installation, maintenance, and potential downtime costs.

A higher-quality valve may offer long-term savings through reliability.

Common Mistakes to Avoid

Avoid these pitfalls to ensure a successful selection:

Underestimating Pressure: A valve rated too close to the system’s maximum risks failure—always include a safety margin.

Ignoring Compatibility: Mismatched materials and fluids can lead to corrosion or leaks.

Overlooking Temperature: Ensure ratings cover the full temperature range.

Price-Only Focus: Cheaper valves may cost more in maintenance or failures.

Skipping Expert Input: Consult manufacturers to avoid oversights.

Maintenance and Troubleshooting Tips

Proper maintenance extends valve life:

Inspection: Regularly check for leaks, corrosion, or wear.

Lubrication: Keep stem threads lubricated to prevent seizing.

Packing Adjustment: Tighten or replace packing if leaks occur.

Cleaning: Remove debris to maintain performance.

Common issues:

Leakage: Replace worn packing or reseat the valve.

Stiff Operation: Lubricate or replace a seized stem.

Inconsistent Flow: Clean out debris.

Conclusion

Selecting the right high-pressure needle valve is a pivotal decision for your system’s safety and efficiency. By evaluating material, pressure rating, temperature range, connection types, flow coefficient, stem design, and standards, you can make an informed choice. Chinese manufacturers offer competitive, high-quality options with innovative features, making them a smart choice for many applications. Assess your needs, consult experts, and consider long-term costs to ensure optimal performance. As your trusted partner, we’re here to help—reach out for expert guidance today.

For more about china high pressure needle valve manufacturer tell you how to select a needle valve, you can pay a visit to Jewellok at https://www.jewellok.com/how-to-find-the-best-china-needle-valve-manufacturer/ for more info.

Recent Posts

Which Gas Pressure Regulator is Best for Laboratory Use?

Complete Guide to Choosing the Best High Pressure Nitrogen Gas Regulator

Tags

Recommended Products

-

JR1300 Series Ultra High Purity Single Stage Regulator High Flow Line Regulator For Ultra High Purity Intermediate Flow

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

Stainless Steel High Pressure Specialty Gas Changeover Manifold For High Purity Oxygen Nitrogen Argon Helium Hydrogen Co2

-

Semi Automatic Oxygen Nitrogen Helium Argon Gas Changeover Manifold Manual Gas Changeover Manifold Panel For Gas Cylinders

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control