Blog

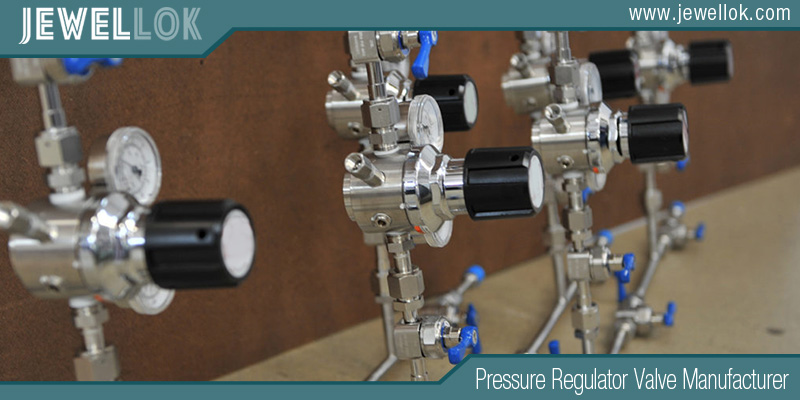

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Dedicated HF Gas Regulators: The Critical Choice Between Monel and Nickel Alloy for CGA 670 Service

- Pressure Regulator Valve Manufacturer

- 316L stainless steel UHP valves, 316L VIM VAR UHP gas regulator, 316L VIM-VAR UHP High Pressure Diaphragm, 316L VIM-VAR UHP High Pressure Diaphragm Sealed Valve, 316L VIM-VAR UHP Taas nga Presyon nga Diaphragm Selyado nga Balbula, applications of UHP valves, biotechnology UHP valve solutions, Changeover Manifold, china high pressure air regulator valve manufacturer, CO2 UHP Gas Pressure Reducing Valve, CO2 UHP Gas Valve, cryogenic UHP valves, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, future trends in UHP valves, gas regulator valve manufacturers, HF gas regulators, high flow needle valve manufacturer, high flow uhp gas pressure regulators, High flow UHP regulator, high pressure ball valve manufacturer, high pressure hydraulic needle valve manufacturer, high pressure needle valve manufacturer, high purity gas pressure regulators manufacturer, high purity gas pressure regulators manufacturers USA, high purity valves manufacturers, hydrogen fluoride (HF) gas regulators, industrial diaphragm valve manufacturers, low pressure valve manufacturer, needle valve 10000 psi manufacturer, pneumatic actuated ball valve manufacturer, pressure control valve manufacturers, pressure gauge manufacturers, pressure reducing valve manufacturers, pressure relief valve manufacturers, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer, Stainless Steel Pressure Regulator, UHP hydrogen fluoride (HF) gas regulators, Ultra High Purity Gas Valves, ultra-high purity hydrogen fluoride (HF) gas regulators

- No Comments

Dedicated HF Gas Regulators: The Critical Choice Between Monel and Nickel Alloy for CGA 670 Service

The handling of anhydrous hydrogen fluoride (HF) gas regulators one of the most demanding challenges in industrial gas control and semiconductor manufacturing. Due to its extreme toxicity, corrosiveness, and propensity to cause catastrophic stress corrosion cracking (SCC), HF requires not just specialized equipment but a fundamental commitment to dedicated system components. At the heart of any HF gas delivery system lies the regulator, a device that must maintain integrity under relentless chemical attack. This article delves into the technical imperative for using dedicated HF regulators, analyzes the material science behind the two primary contenders—Monel and specialized nickel alloys—and examines the non-negotiable role of the CGA 670 connection. We will explore corrosion mechanisms, mechanical performance, industry standards, and provide a framework for selecting the appropriate material for specific HF applications.

- The Unforgiving Nature of Anhydrous Hydrogen Fluoride

Anhydrous hydrogen fluoride, a cornerstone chemical for etching, cleaning, and synthesis in the semiconductor, pharmaceutical, and petrochemical industries, is not merely “corrosive.” It is a penetrative and reactive acid gas that attacks most metallic and ceramic materials. In the presence of even trace moisture, it forms hydrofluoric acid, which dissociates into highly reactive fluoride ions (F⁻). These ions are exceptionally small and mobile, enabling deep penetration into material matrices. The primary failure modes for regulators in HF service are:

- Uniform Corrosion: General thinning of components.

- Stress Corrosion Cracking (SCC): The most prevalent and dangerous failure. Under tensile stress (inherent in regulator springs, diaphragm beams, and valve seats) and in the presence of HF, cracks initiate and propagate, often leading to sudden, brittle fracture without warning.

- Pitting and Crevice Corrosion: Localized attack at imperfections or stagnant areas.

A “dedicated” regulator for HF means a unit that is never used with any other gas, is constructed entirely of compatible materials, and is designed for maximum integrity. Using a non-dedicated or incorrectly specified regulator risks catastrophic leaks, posing severe safety hazards, environmental contamination, and costly production downtime.

- The Material Showdown: Monel vs. Nickel Alloy

The selection of a HF gas regulator body, diaphragm, and internal component materials is the single most critical engineering decision. While both Monel and nickel alloys belong to the nickel-based family, their compositions and performance differ significantly.

2.1 Monel: The Traditional Workhorse

Monel, a nickel-copper alloy (typically UNS N04400, ~67% Ni, 30% Cu, with small amounts of Fe and Mn), has been the traditional material of choice for HF service for decades.

- Corrosion Resistance: Monel forms a stable, adherent fluoride film (primarily nickel fluoride, NiF₂) upon exposure to dry HF. This passive layer protects the underlying metal from further rapid attack, provided the film remains intact and the HF remains anhydrous.

- Mechanical Properties: It offers good mechanical strength, toughness, and is readily machinable, making it suitable for complex regulator components.

- Limitations and Vulnerabilities:

- Moisture Sensitivity: The protective film on Monel is less stable in the presence of moisture. Wet HF service or inadvertent exposure to humid air can break down this layer, accelerating corrosion.

- Stress Corrosion Cracking Susceptibility: Monel is susceptible to SCC in HF environments, particularly at elevated temperatures and under high tensile stress. This makes the design and heat treatment of Monel components (like springs) crucial.

- Temperature Constraints: Performance degrades at sustained temperatures above 150°C (300°F).

2.2 Nickel Alloys: The Engineered Solutions

This category encompasses purer nickel (UNS N02200/N02201) and advanced alloys like Hastelloy® C-276 (UNS N10276) or Alloy 625 (UNS N06625). For HF, the most common is often pure nickel or a nickel-molybdenum alloy.

- Pure Nickel (UNS N02200/201): Offers exceptional resistance to dry and wet HF across a wide temperature range. It forms a highly stable NiF₂ layer. Its superior SCC resistance compared to Monel makes it preferred for high-reliability applications like semiconductor manufacturing.

- Hastelloy C-276: A nickel-molybdenum-chromium superalloy with outstanding resistance to both oxidizing and reducing environments. It is highly resistant to pitting, crevice corrosion, and SCC in HF, especially where trace oxidants or moisture may be present. It is often the material of choice for the most severe conditions, including hot HF vapors.

- Advantages:

- Broader Compatibility: Superior performance across a wider range of HF purity (dry to slightly wet) and temperature.

- Enhanced SCC Resistance: Generally demonstrate a higher threshold stress for SCC initiation.

- Higher Temperature Capability: Alloys like C-276 can operate effectively at much higher temperatures.

2.3 Comparative Analysis

| Property | Monel 400 | Pure Nickel (200/201) | Nickel-Moly Alloy (e.g., C-276) |

| Primary Composition | Ni (~67%), Cu (~30%) | Ni (>99%) | Ni (~57%), Mo (~16%), Cr (~15%) |

| HF Corrosion Resistance | Excellent in dry, anhydrous HF. Good in moist HF at low temps. | Excellent in both dry and moist HF. | Exceptional in dry, wet, and contaminated HF. |

| SCC Resistance in HF | Moderate. Requires careful design and stress relief. | High. | Very High. |

| Max Service Temp (HF) | ~150°C (300°F) | ~315°C (600°F) | ~400°C+ (750°F+) |

| Cost | Moderate | Higher than Monel | Significantly Higher |

| Machinability | Good | Fair (gummy) | Difficult |

| Typical Use Case | Well-controlled, dry HF bulk systems, lower-risk processes. | High-purity semiconductor fab lines, etch processes. | Severe service, HF with impurities, R&D, high-temp applications. |

- The CGA 670 Connection: A Standard for Safety

The Compressed Gas Association (CGA) connection standard CGA 670 is intrinsically linked to HF gas cylinders. It is a left-handed thread connection with a specific geometry.

- Purpose: The left-handed (reverse) thread is a key safety feature. It physically prevents the accidental connection of an HF regulator to a cylinder of incompatible gas (like oxygen or fuel gas), which use right-handed threads. This “non-interchangeability” is a primary defense against catastrophic human error.

- Material Specification: The CGA 670 standard itself does not mandate a specific material for the nipple or nut. However, industry best practice and regulator manufacturers always produce CGA 670 inlets from HF-compatible materials—invariably Monel or a nickel alloy. Using a brass or stainless steel CGA 670 inlet would defeat the purpose.

- System Integrity: The connection is the first point of gas entry. Any corrosion or SCC here would lead to a leak at the cylinder valve, the most hazardous location. Therefore, the material choice for the inlet must match or exceed the corrosion resistance of the regulator body itself.

- Beyond the Body: Critical Internal Components

A regulator is only as strong as its weakest part. Material selection must be holistic:

- Diaphragm: The sensing element. Typically a Monel or nickel alloy metal diaphragm, or in some designs, a PTFE-coated elastomer (for lower pressures). A solid metal diaphragm eliminates permeation risk.

- Springs: Highly susceptible to SCC as they are under constant tensile stress. Must be manufactured from compatible materials (often Inconel® X-750 or Elgiloy® for Monel bodies, and specially treated nickel alloys for nickel bodies) and undergo proper stress-relief treatments.

- Valve Seat: Experiences constant wear and exposure. Often uses PTFE or Kalrez® perfluoroelastomer for a tight seal, backed by a Monel or nickel stem.

- Fasteners & Internal Parts: Every screw, pin, and seal must be evaluated for HF compatibility. Nickel-plated or alloy steel is unacceptable.

- Selection Guidelines and Best Practices

Choosing between a Monel and a nickel alloy regulator involves a risk-based assessment:

- Process Criticality: For mission-critical semiconductor fabrication tools where an unplanned release could cost millions, the superior reliability of a pure nickel or C-276 regulator justifies its higher capital cost.

- Gas Purity and Conditions: If absolute control over moisture is guaranteed and temperatures are mild, Monel is a proven, cost-effective solution. For processes with potential moisture ingress, varying purity, or higher temperatures, a nickel alloy is mandatory.

- Total Cost of Ownership (TCO): While the upfront cost of a nickel alloy regulator can be 2-3x that of a Monel unit, the TCO must factor in the cost of potential failures: safety incidents, production halts, and equipment damage. In high-risk environments, the nickel alloy’s extended service life and reduced failure risk often result in a lower TCO.

- Industry Standards and Codes: Adhere to guidelines from SEMI (Semiconductor Equipment and Materials International), CGA, and internal corporate safety standards, which increasingly mandate the highest integrity materials for toxic gases.

Best Practices for Operation:

- Dedication: Clearly label the regulator “HF SERVICE ONLY.”

- Purge Protocol: Always use a dedicated, compatible purge gas (like dry nitrogen) for regulator pressurization and depressurization to avoid air/moisture ingress.

- Inspection & Maintenance: Establish a strict schedule for visual inspection, leak testing, and internal inspection for signs of corrosion or cracking. Record all service history.

- Training: Ensure personnel are trained on the specific hazards of HF and the unique handling requirements of its dedicated equipment.

- Conclusion

The selection of a dedicated HF gas regulator is a fundamental safety and reliability decision, not merely a purchasing specification. The choice between Monel and nickel alloy hinges on a detailed understanding of the application’s specific conditions—temperature, moisture potential, stress levels, and consequence of failure.

Monel remains a robust and economically viable choice for well-controlled, anhydrous HF applications where cost sensitivity is a factor. However, for the stringent demands of modern high-tech industries, particularly semiconductor manufacturing, the enhanced corrosion and stress corrosion cracking resistance of advanced nickel alloys like pure nickel or Hastelloy C-276 provides an indispensable margin of safety and operational assurance. Paired irrevocably with the safety-engineered CGA 670 connection, these materials form the bedrock of a responsible HF gas handling system. In the realm of hydrogen fluoride, where the stakes are measured in human safety and operational continuity, investing in the highest practicable level of material integrity is not an extravagance; it is an engineering imperative.

For more about dedicated HF gas regulators: the critical choice between monel and nickel alloy for CGA 670 service, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

767LT Reducer Pressure Reducing Valve Adjustment High purity Pressure Reducing Union Fittings And Tubing

-

772L Male Branch Tee | Stainless Steel High-Purity Tube Fitting Male Branch Tee

-

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

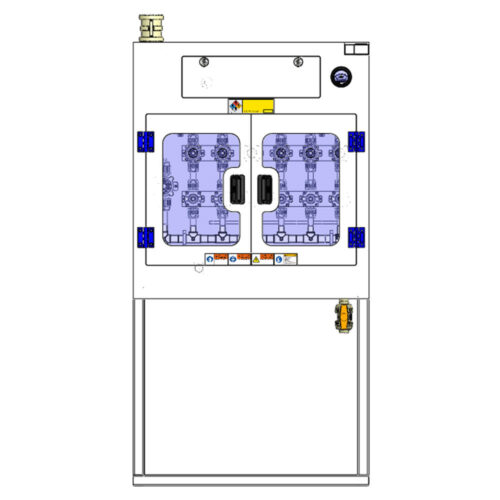

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

High Purity High Pressure 316 Stainless Steel Ball Valves JBV1 Series From High Pressure Ball Valve Manufacturer And Supplier In China

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions