Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How to Select Ultra-High Purity Hydrogen Fluoride (HF) Gas Regulators

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, Back Pressure Regulating Valve, back pressure regulator manufacturers, best high purity gas pressure regulator, best high purity gas pressure regulators manufacturer, best high purity gas pressure regulators manufacturers USA, Brass Pressure Regulator, Changeover Manifold, china high pressure air regulator valve manufacturer, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, gas regulator valve manufacturers, high flow needle valve manufacturer, high pressure ball valve manufacturer, high pressure hydraulic needle valve manufacturer, high pressure needle valve manufacturer, high purity gas pressure regulators manufacturer, high purity gas pressure regulators manufacturers USA, high purity valves manufacturers, hydrogen fluoride (HF) gas regulators, industrial diaphragm valve manufacturers, low pressure valve manufacturer, medical oxygen pressure gauge manufacturer, needle valve 10000 psi manufacturer, pneumatic actuated ball valve manufacturer, pressure control valve manufacturers, pressure gauge manufacturers, pressure reducing valve manufacturers, pressure relief valve manufacturers, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer, Stainless Steel Pressure Regulator, Ultra High Purity Gas Valves, ultra-high purity HF gas regulators, ultra-high purity hydrogen fluoride (HF) gas regulators

- No Comments

How to Select Ultra-High Purity Hydrogen Fluoride (HF) Gas Regulators

The relentless drive towards smaller features and higher performance in semiconductor manufacturing, photovoltaics, and advanced electronics places extraordinary demands on every component within the supply chain. Process gases, particularly ultra-high purity (UHP) gases, are the lifeblood of these industries. Among them, anhydrous Hydrogen Fluoride (HF) gas is a critical yet notoriously challenging material, essential for etching silicon dioxide, cleaning chemical vapor deposition chambers, and other precision processes. Its selection, handling, and delivery are paramount, with the gas regulator being the single most critical interface between the gas source and the process tool. A poorly chosen regulator can introduce catastrophic contamination, cause unsafe leaks, or lead to inconsistent process results. Therefore, selecting the correct UHP HF gas regulator is not merely a procurement decision but a fundamental process safety and yield assurance activity. This article provides a comprehensive, technical guide on the key factors to consider when selecting a regulator for ultra-high purity HF gas service.

Understanding the Adversary – The Nature of UHP HF Gas

To select the proper containment, one must first understand the properties of the substance. Anhydrous HF gas presents a unique triad of challenges:

- Extreme Corrosivity and Reactivity: HF reacts violently with moisture to form hydrofluoric acid. It aggressively attacks glass, silica, and many metals, especially those with oxide layers. It can catalyze reactions with organic materials and is incompatible with most elastomers and lubricants.

- Ultra-High Purity Requirements: In semiconductor fabrication, HF purity often exceeds 99.999% (5.0 grade) and can reach 99.9999% (6.0 grade) or higher. The permissible levels of specific contaminants—such as moisture (H₂O), metallic ions (e.g., Na⁺, K⁺, Fe²⁺/³⁺, Al³⁺), particles, and other acid gases—are measured in parts per billion (ppb) or even parts per trillion (ppt). The regulator must not add any of these contaminants.

- Acute Toxicity and Health Hazard: HF is a highly toxic gas and contact hazard. Permissible exposure limits (PELs, OSHA) are very low (3 ppm as an 8-hour TWA). Leaks are unacceptable from both a safety and process integrity standpoint.

These properties mandate that a UHP HF regulator be more than just a pressure-control device; it must be a hermetically sealed, ultra-clean, inert, and passive component.

Core Selection Criteria – A Detailed Breakdown

- Material of Construction: The Foundation of Integrity

The choice of materials is the foremost consideration, directly impacting purity, safety, and longevity.

- Body and Internal Components: The universal standard is high-nickel alloys, prized for forming a stable, passive fluoride layer that halts further corrosion.

- Monel® (Alloy 400/ UNS N04400): A nickel-copper alloy. It is highly resistant to anhydrous HF and is the most common and cost-effective choice for many HF applications. However, under certain conditions (e.g., presence of oxygen and moisture), it can be susceptible to higher corrosion rates.

- Alloy C-22 (Hastelloy® C-22 / UNS N06022): A nickel-chromium-molybdenum-tungsten alloy. Offers superior resistance across a wider range of conditions, including against pitting and crevice corrosion. It is often preferred for the most stringent, high-reliability applications and provides a greater safety margin.

- Electroless Nickel Plating (ENP): Sometimes applied to stainless steel bodies for lower-grade applications. This is categorically unsuitable for UHP HF. The plating can be porous, and HF will penetrate it, corroding the underlying steel, leading to catastrophic failure, particle generation, and metallic contamination.

- Diaphragm: This is the heart of the regulator, separating the process gas from the spring chamber. It must be impermeable and non-reactive.

- All-Metal Diaphragms: The only acceptable choice for UHP HF. Typically made from a thin, corrugated disk of Alloy C-276 or 316L Stainless Steel. They offer zero permeability, eliminate a potential elastomeric contamination source, and are exceptionally leak-tight. Metal diaphragms are a hallmark of true UHP and corrosive gas service.

- Seals (Gaskets & Seat): Like the diaphragm, these must be all-metal to maintain purity and compatibility.

- Seat: Usually a knife-edge configuration on the metal diaphragm sealing against a polished metal orifice.

- Static Seals (Body Gaskets): Metal (e.g., Nickel or Silver-plated) C-Ring or Delta® Seals are standard. They provide a helium-leak-tight seal (typically < 1 x 10⁻⁹ atm cc/sec He) and withstand temperature cycling. Elastomeric O-rings (even perfluoroelastomers like Kalrez®) are not acceptable for primary sealing in UHP HF service.

- Surface Finish and Cleanliness: Controlling Particulates

A smooth, clean internal surface minimizes particle generation and adsorption sites for moisture.

- Surface Finish: Internal gas-wetted surfaces should be polished to an electropolished finish with a Ra (average roughness) of ≤ 15 micro-inches (0.38 µm) or better. Electropolishing not only smoothes the surface but also passivates it, enhancing corrosion resistance.

- Cleaning and Packaging: The regulator must undergo a rigorous cleaning protocol for UHP service. This typically involves solvent cleaning, ultrasonic baths, high-purity DI water rinses, and baking under vacuum or in an inert atmosphere to remove volatile residues. It should be double-bagged under an inert atmosphere (Nitrogen or Argon) in a certified cleanroom environment (Class 10 or better) and sealed with documentation of cleanliness levels (e.g., particle counts).

- Design Features for Purity and Safety

- Hermetic Design: The regulator must be hermetically sealed to prevent atmospheric in-leakage (which introduces moisture and oxygen) and process gas out-leakage. This is achieved through welded construction of the diaphragm capsule and the use of metal-sealed stems and adjustment assemblies.

- Purge and Vent Configurations: For critical applications, regulators often feature Dual Diaphragm (or “Barrier”) Isolation with an intermediate purge chamber. A clean, dry inert purge gas (e.g., N₂) can be continuously flowed into this chamber. This provides a failsafe: if the primary process-side diaphragm fails, HF is contained and directed to a scrubber via the vent port, while the purge gas prevents atmospheric contamination. The purge also acts as a buffer against back-diffusion.

- Outlet Pressure Gauge: If a gauge is required, it must be of UHP compatibility, typically with a Monel or Alloy C-22 Bourdon tube and a Teflon®-isolated face in case of diaphragm rupture. Many systems opt for electronic pressure transducers instead to avoid potential gauge failure modes.

- Inlet/Outlet Connections: VCR® (metal gasket face seal) or VCO® connections are the standard for UHP systems. They provide a ultra-high integrity, leak-tight seal and are conducive to proper installation and torque procedures. Avoid NPT (tapered thread) connections as they are prone to leakage and can generate particles.

- Operational Performance Specifications

- Delivery Pressure Range & Stability: Ensure the regulator’s outlet pressure range and spring options match your process requirements (e.g., 0-50 psig, 0-100 psig). Stability, often measured as droop (lock-up) or supply pressure effect, should be minimal. For critical mass flow controller (MFC) inlet pressure regulation, a stability of ±0.1 psig or better may be required.

- Flow Capacity (Cv): Select a Cv value appropriate for your maximum required flow rate. An undersized regulator will struggle to maintain set pressure at high flows, while an oversized one may be less stable at very low flows.

- Leak Integrity: Specify and verify ultra-low leak rates. External leak rates should be < 1 x 10⁻⁹ atm cc/sec He for all seals. Internal leak rates (across the seat when closed) should also be exceptionally low to prevent creeping pressure rise downstream when the system is idle.

Selection Process and Best Practices

- Define the Application Precisely: Document the gas grade (e.g., SEMI C3.45 Specification), required delivery pressure and flow ranges, upstream source pressure, and the criticality of the downstream process.

- Engage with Specialized Suppliers: Source regulators only from manufacturers with a proven track record in UHP and corrosive gas handling. Do not use standard industrial or even standard “clean” regulators for HF.

- Specify and Document: Create a formal procurement specification that includes all critical items: Material (Alloy C-22 body, metal diaphragm), Surface Finish (Electropolished, Ra ≤ 15 µin), Connections (1/4″ VCR), Cleanliness (Double-bagged, N₂ purged, particle count cert), and Performance (Leak rate < 1×10⁻⁹, Outlet range).

- Inspect Upon Receipt: Verify packaging integrity, review certification packets (Material Certificates, Cleanliness Certificates, Leak Test Reports), and perform a helium leak check on the installed regulator before introducing HF.

- Implement Safe Handling Procedures: Always use proper PPE (acid-resistant gloves, face shield, FR lab coat) and have emergency response protocols (calcium gluconate gel) in place when connecting or disconnecting regulators.

- Establish a Maintenance and Replacement Schedule: Even the best regulators have a service life in HF duty. Establish a proactive replacement schedule based on manufacturer recommendations and internal performance monitoring (e.g., increased creep, difficulty in tuning). Never run a regulator to failure in this service.

Conclusion

Selecting a regulator for ultra-high purity Hydrogen Fluoride gas is a critical engineering decision that balances materials science, precision engineering, and stringent safety protocols. The paradigm shifts from a simple pressure-reducing valve to specifying a high-integrity containment system. The non-negotiable tenets are: all-metal wetted surfaces (preferably high-nickel alloys), a hermetically sealed, metal diaphragm design, ultra-smooth electropolished finishes, and UHP cleaning and packaging. By systematically evaluating the application requirements against these technical criteria and partnering with qualified suppliers, engineers can ensure the safe, reliable, and contamination-free delivery of this essential but hazardous process gas, thereby safeguarding both personnel and the delicate processes at the heart of modern technology.

For more about how to select ultra-high purity hydrogen fluoride (HF) gas regulators, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

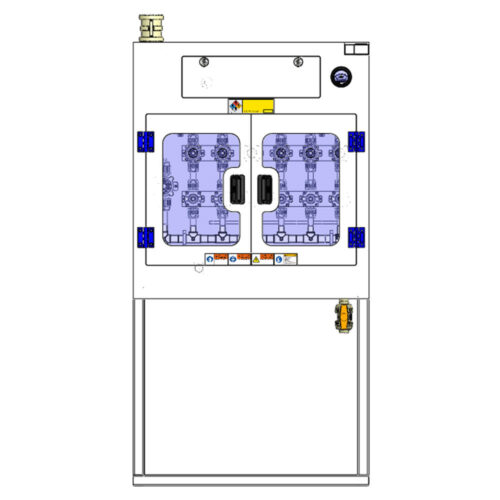

Semi-Automatic VMB Gas Cabinet With Semiconductor Valve Manifold Box Diaphragm Valves And Gas Pressure Regulators

-

High Purity Semi-Auto Stainless Steel Changeover Manifold System, Nitrogen High Pressure Control Panel With Semiconductor Valve Manifold Box Diaphragm Valves

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

UHP Metal Gasket Face Seal Fittings Vacuum Coupling Metal Face Seal Join Long Gland And Short Gland

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

Ultra High Purity Stainless Steel Compressed Gas Changeover Manifold Panel System For Integrated Gas Supply System