Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Safety Valves vs. Pressure Relief Valves – What’s the Difference?

- Pressure Regulator Valve Manufacturer

- 1/2 gas pressure regulator, 2 inch irrigation solenoid valve, 6mm compression union, 6mm equivalent, adjustable propane pressure regulator, adjustable propane regulator, argon gas pressure regulator, argon hose fitting, characteristics of pressure, diaphragm suppliers, Diaphragm Valve Manufacturers, gas filter, gas manifold system, gas used in semiconductor manufacturing, high purity regulator, how a solenoid works, how does pressure regulator work, how often should pressure relief valves be replaced, how solenoid valves work, industrial grade purity, industrial regulators, low pressure regulator, oxygen regulator gauge, pressure gauge manufacturers, pressure relief valve vs safety valve, pressure relief valves, pressure relief valves factory, pressure relief valves manufacturer, relief valve and safety valve difference, relief vs safety valve, safety relief valve vs pressure relief valve, safety relief valve vs safety valve, safety valve and relief valve difference, safety valve vs relief valve, Safety Valves, semiconductor gas, solenoid water valve, stainless pressure regulator, stainless steel 1/4 in, what is a gas pressure regulator

- No Comments

Safety Valves vs. Pressure Relief Valves – What’s the Difference?

In industries handling pressurized systems—such as oil and gas, chemical processing, hydrogen energy, power generation, pharmaceuticals, and manufacturing—ensuring safety is paramount. Over-pressurization in pipelines, vessels, or reactors can lead to catastrophic failures, including explosions, leaks, equipment damage, or environmental harm. Two critical devices, safety valves and pressure relief valves (PRVs), are designed to mitigate these risks by releasing excess pressure to protect systems and personnel. While the terms are sometimes used interchangeably, safety valves and PRVs have distinct designs, functions, and applications. Understanding their differences is essential for selecting the right device, ensuring compliance with regulations, and maintaining operational safety. This article compares safety valves and PRVs, exploring their definitions, mechanisms, applications, standards, and practical considerations to clarify their roles and guide effective decision-making.

Defining Safety Valves and Pressure Relief Valves

Safety Valves

A safety valve is a mechanical device designed to automatically release pressure from a system when it exceeds a predetermined set pressure, preventing catastrophic failure. Safety valves are typically used in systems handling gases or vapors, such as steam, air, or hydrogen, and are characterized by their rapid, full-lift opening to quickly vent large volumes of fluid. Once the pressure drops to a safe level, the valve reseats, stopping the release. Safety valves are commonly associated with boilers, pressure vessels, and gas systems, where rapid pressure relief is critical to prevent explosions or ruptures.

Key Features:

- Rapid, full-lift opening for quick pressure release.

- Primarily used for gases, vapors, or steam.

- Designed for high-capacity relief in critical applications.

- Often spring-loaded or pilot-operated for precise operation.

Pressure Relief Valves (PRVs)

A pressure relief valve (PRV) is a broader category of safety device that opens to release excess pressure and closes when pressure returns to a safe level. PRVs are versatile, used for liquids, gases, or mixed-phase fluids, and are designed to provide controlled, proportional relief to maintain system stability. Unlike safety valves, PRVs may open gradually, depending on the pressure increase, and are used in a wide range of applications, including pipelines, reactors, and storage tanks. PRVs are often referred to as pressure safety valves (PSVs) in specific contexts, such as oil and gas.

Key Features:

- Proportional or modulated opening for controlled relief.

- Suitable for liquids, gases, or mixed-phase fluids.

- Versatile for various applications, from low to high pressure.

- Available in spring-loaded, pilot-operated, or bellows-sealed designs.

Terminology Note: In some industries (e.g., oil and gas), “safety valve” and “pressure safety valve (PSV)” are used synonymously, but safety valves are technically a subset of PRVs optimized for gas/vapor applications. This article uses the distinct definitions to clarify their differences.

Design and Mechanism

Safety Valves

Safety valves are engineered for rapid response and high-capacity relief, typically in gas or vapor systems. Their design emphasizes quick, full-lift action to vent pressure surges effectively.

- Spring-Loaded Safety Valves:

- A spring holds the valve disc against the seat, keeping it closed under normal pressure.

- When system pressure exceeds the set point, the force overcomes the spring, lifting the disc fully to release gas or vapor.

- A blowdown ring adjusts the reseat pressure, ensuring the valve closes after relief.

Pilot-Operated Safety Valves:

- Use a pilot valve to sense system pressure and control the main valve’s opening.

- Offer precise control for high-pressure or large-diameter systems (e.g., hydrogen pipelines)

Components: Include a nozzle, disc, spring, blowdown ring, and body, often made of stainless steel or high-nickel alloys for corrosion resistance.

Operation: Full-lift opening maximizes flow capacity, critical for applications like steam boilers where rapid venting prevents explosions.

Example: In a power plant boiler, a safety valve opens fully at 100 barg to release steam, reseating at 95 barg to restore normal operation.

Pressure Relief Valves

PRVs are designed for versatility, handling a broader range of fluids and applications. Their operation is often proportional, allowing controlled relief to maintain system stability.

Spring-Loaded PRVs:

- Similar to safety valves but open gradually based on pressure increase, suitable for liquids or gases.

- Adjustable set pressures and blowdown settings allow customization.

Pilot-Operated PRVs:

- Use a pilot to modulate opening, ideal for high-pressure or variable backpressure systems (e.g., oil pipelines).

Bellows-Sealed PRVs:

- Incorporate a bellows to isolate the spring from process fluid, protecting against corrosive liquids or backpressure.

Components: Include a disc, seat, spring or pilot, and body, with materials like 316L stainless steel, Hastelloy, or PTFE for compatibility.

Operation: Proportional opening adjusts flow based on pressure, minimizing fluid loss and system disruption.

Example: In a chemical reactor, a PRV opens partially at 50 barg to release liquid ammonia, modulating flow to maintain pressure without emptying the system.

Key Design Difference: Safety valves prioritize rapid, full-lift relief for gases/vapors, while PRVs offer proportional relief for diverse fluids, balancing safety and system efficiency.

Functional Differences

Safety Valves

Primary Function: Prevent catastrophic over-pressure in gas/vapor systems by rapidly venting large volumes.

Response Time: Immediate, full-lift action to address sudden pressure spikes (e.g., boiler steam surges).

Fluid Loss: High, as the focus is on safety over fluid conservation.

Reseat Behavior: Reseats after significant pressure drop (blowdown), designed for infrequent activation in critical scenarios.

Example Application: A safety valve on a hydrogen storage tank opens fully to vent gas during an over-pressure event, preventing tank rupture.

Pressure Relief Valves

Primary Function: Maintain system pressure within safe limits for liquids, gases, or mixed fluids, often with controlled release.

Response Time: Gradual or proportional opening to match pressure increase, reducing unnecessary fluid loss.

Fluid Loss: Minimized through modulated relief, preserving process fluid where possible.

Reseat Behavior: Reseats closer to set pressure, allowing frequent operation in dynamic systems.

Example Application: A PRV on a water pipeline opens partially to release excess pressure during pump startup, maintaining flow stability.

Key Functional Difference: Safety valves are optimized for emergency, high-capacity gas relief, while PRVs provide controlled, versatile relief for a broader range of fluids and scenarios.

Applications

Safety Valves

Safety valves are used in applications requiring rapid gas or vapor relief:

Power Generation: Protecting steam boilers, turbines, and superheaters from over-pressure (e.g., ASME Section I applications).

Hydrogen Energy: Safeguarding high-pressure hydrogen systems in fuel cells, refueling stations, or electrolysis plants (e.g., NFPA 56 compliance).

Oil and Gas: Venting gas in upstream wellheads or downstream compressors.

Chemical Processing: Releasing vapor in reactors handling volatile gases like ethylene.

Aerospace: Managing propellant gases in rocket propulsion systems.

Example: A safety valve on a steam boiler opens at 150 barg to release excess steam, preventing boiler explosion.

Pressure Relief Valves

PRVs are used in diverse applications involving liquids, gases, or mixed fluids:

Oil and Gas: Protecting pipelines, storage tanks, and refineries from liquid or gas over-pressure (e.g., API 520/526 applications).

Chemical Processing: Controlling pressure in reactors with liquid chemicals or mixed-phase fluids (e.g., ammonia, sulfuric acid).

Pharmaceuticals: Ensuring safe pressure in sterile liquid systems for drug production.

Water Treatment: Managing pressure in water or wastewater pipelines.

HVAC Systems: Releasing refrigerant gases or liquids in chillers.

Example: A PRV on an oil pipeline opens at 80 barg to release crude oil, maintaining safe pressure during transport.

Key Application Difference: Safety valves are specialized for gas/vapor systems in high-risk, rapid-relief scenarios, while PRVs are versatile for liquid, gas, or mixed-phase systems across a wider range of applications.

Regulatory and Industry Standards

Both safety valves and PRVs are subject to stringent regulations to ensure safety and compliance. However, standards may emphasize different aspects based on their applications.

Safety Valves

ASME Section I: Governs safety valves for power boilers, requiring annual testing and specific design criteria (e.g., full-lift, blowdown settings).

ASME Section VIII: Applies to safety valves for pressure vessels, mandating testing every 1–5 years based on risk.

NFPA 56: Specifies safety valve requirements for hydrogen systems, emphasizing leak prevention and rapid relief.

ISO 4126-1: Defines safety valve standards globally, focusing on gas/vapor applications.

EN 13445: European standard for pressure equipment, including safety valves.

Pressure Relief Valves

API 520/526: Provides guidelines for PRV sizing, selection, and testing in oil and gas, recommending testing every 1–5 years.

ASME Section VIII: Covers PRVs for pressure vessels, with similar testing requirements as safety valves.

OSHA 1910.119: Mandates process safety management (PSM) for PRVs in hazardous chemical processes.

ISO 4126-4: Addresses pilot-operated PRVs, emphasizing versatility for liquids and gases.

EPA Regulations: Govern PRV emissions, requiring treatment for hazardous gases (e.g., Clean Air Act).

Key Regulatory Difference: Safety valves are tightly regulated for gas/vapor applications (e.g., boilers, hydrogen systems), while PRVs face broader standards covering diverse fluids and industries.

Action: Verify compliance with relevant standards (e.g., ASME, API, ISO) and maintain documentation for inspections.

Practical Differences and Selection Criteria

When choosing between safety valves and PRVs, consider the following factors:

- Fluid Type

Safety Valves: Best for gases or vapors (e.g., steam, hydrogen, nitrogen).

PRVs: Suitable for liquids, gases, or mixed-phase fluids (e.g., oil, water, ammonia).

Action: Identify the process fluid and select the valve type accordingly.

- Application Requirements

Safety Valves: Ideal for emergency, high-capacity relief in gas systems (e.g., boilers, hydrogen tanks).

PRVs: Preferred for controlled relief in dynamic or liquid-based systems (e.g., pipelines, reactors).

Action: Assess whether rapid, full-lift relief or proportional control is needed.

- Operating Conditions

Safety Valves: Designed for high-pressure, high-temperature gas systems with infrequent activation.

PRVs: Handle a wider range of pressures, temperatures, and fluids, with frequent or modulated operation.

Action: Specify pressure, temperature, and duty cycle to ensure compatibility.

- Maintenance and Testing

Safety Valves: Require regular testing (e.g., annually for boilers) due to critical safety roles, with bench testing for precision.

PRVs: Testing intervals vary (e.g., 1–5 years), with in-situ testing often sufficient for non-critical systems.

Action: Develop a maintenance schedule based on risk, standards, and valve type.

- Cost and Complexity

Safety Valves: Often simpler but may require robust materials for high-pressure gas applications, increasing costs.

PRVs: More versatile but can be complex (e.g., pilot-operated designs), with higher initial or maintenance costs.

Action: Balance upfront costs with total cost of ownership (TCO), considering maintenance and downtime.

Testing and Maintenance Considerations

Both valve types require regular testing and maintenance to ensure reliability:

Testing Methods:

Bench Testing: Remove and test on a certified bench to verify set pressure, blowdown, and reseat (ASME PTC 25, API 527).

In-Situ Testing: Use portable devices to test without removal, minimizing downtime.

Pop Testing: Briefly trigger the valve in operation (riskier, used sparingly).

Testing Frequency:

Safety valves: 6–12 months for high-risk gas systems (e.g., boilers, hydrogen).

PRVs: 1–5 years, depending on fluid and risk level.

Maintenance:

Inspect for corrosion, seat damage, or spring fatigue.

Replace seals, bellows, or pilots as needed.

Calibrate set pressure after repairs.

Replacement:

Safety valves: Replace every 5–10 years or if they fail tests.

PRVs: Replace every 5–12 years, depending on design and condition.

Action: Follow manufacturer guidelines and standards (e.g., API 510, ASME BPVC) for testing and maintenance schedules.

Challenges and Solutions

Challenge: Misapplication of valve type.

Solution: Consult fluid and application data to choose safety valves for gases or PRVs for liquids/mixed fluids.

Challenge: Regulatory compliance across regions.

Solution: Adopt global standards (e.g., ISO 4126) and engage compliance experts.

Challenge: Downtime during testing.

Solution: Use in-situ testing or redundant valves to maintain operations.

Challenge: Cost of maintenance.

Solution: Prioritize TCO and invest in durable, high-quality valves.

Emerging Trends

Innovations are enhancing both safety valves and PRVs:

Smart Valves: IoT sensors monitor pressure, temperature, and performance, enabling predictive maintenance.

Digital Twins: Virtual models optimize valve selection and maintenance schedules.

Sustainable Materials: Eco-friendly alloys and coatings extend valve life and reduce environmental impact.

Automated Testing: Portable, automated test rigs improve accuracy and reduce labor.

Impact: These advancements improve reliability, compliance, and cost-efficiency.

Case Studies

Power Plant (UK): Safety valves on a steam boiler were tested annually per ASME Section I, ensuring zero incidents and compliance. Replacement every 7 years maintained reliability.

Oil Refinery (USA): Pilot-operated PRVs on crude oil pipelines were tested every 2 years per API 510, reducing downtime with in-situ methods and saving $200,000 annually.

Hydrogen Facility (Japan): Smart safety valves with IoT monitoring on 700-bar hydrogen tanks enabled predictive maintenance, extending valve life by 20%.

Conclusion

Safety valves and pressure relief valves are both essential for protecting pressurized systems, but they serve distinct roles. Safety valves are specialized for rapid, full-lift relief of gases and vapors in high-risk applications like boilers and hydrogen systems, while PRVs offer versatile, proportional relief for liquids, gases, or mixed fluids across diverse industries. Their differences in design, function, applications, and regulatory requirements necessitate careful selection based on fluid type, operating conditions, and safety needs. By understanding these distinctions, adhering to standards like ASME, API, and ISO, and implementing regular testing and maintenance, organizations can ensure safety, compliance, and efficiency. Emerging technologies like smart valves and digital twins are further enhancing their performance, reducing costs, and improving reliability. Whether safeguarding a steam boiler or an oil pipeline, choosing the right valve—safety or PRV—is a critical decision that drives safety and success in industrial operations.

For more about safety valves vs. pressure relief valves – what’s the difference?, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Adjustable Low Pressure Propane Regulator

Pressure Control Valve Manufacturers

High Flow Needle Valves manufacturers

Tags

Recommended Products

-

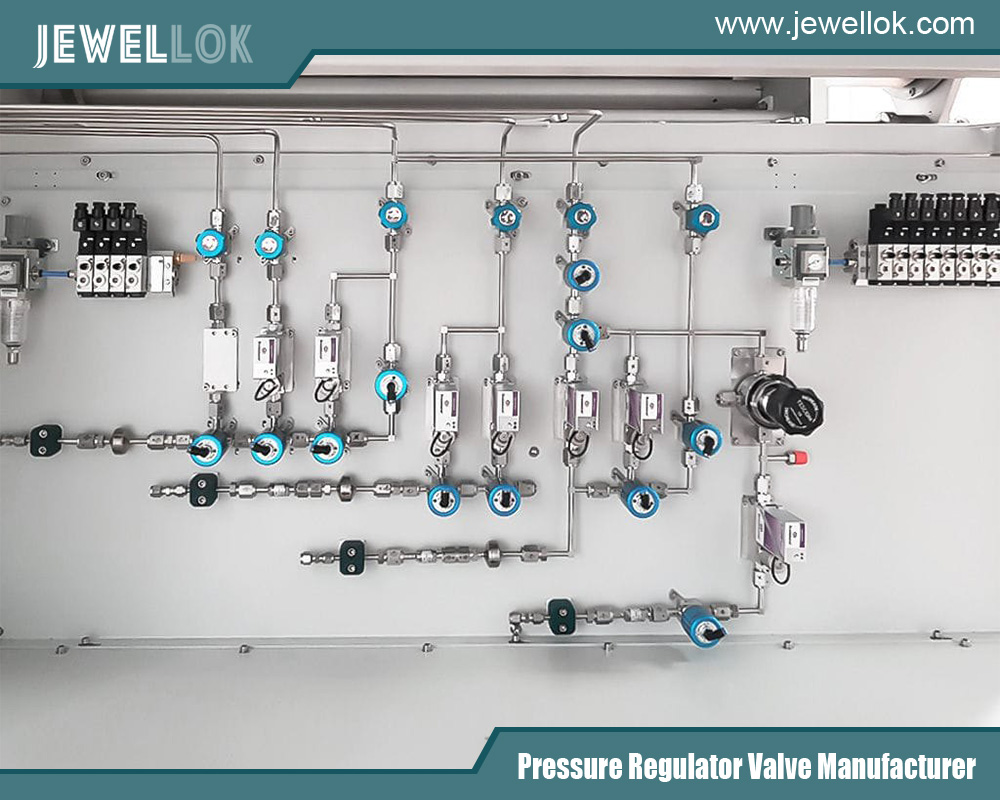

Stainless Steel Single Stage Semiconductor Grade Pressure Control Module Pressure Control Panels JSP-6A Series

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases

-

Ultra High Purity Pressure Gauge For Laboratory And Semiconductor JR Series