Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Ultra High Purity High Pressure Diaphragm Valve: A Critical Component in Advanced Industrial Applications

- Pressure Regulator Valve Manufacturer

- 316L stainless steel valve, biopharmaceutical valve, clean in place valve, diaphragm valve design, electropolished valve body, future trends in UHP valves, helium leak testing valve, high pressure valve maintenance, High Purity Gas Delivery System, high-pressure diaphragm valve, nanocomposite diaphragm valve, particle generation in valves, pharmaceutical diaphragm valve, photovoltaic gas valve, pneumatic actuated diaphragm valve, quantum computing gas valve, SEMI standard valve, semiconductor gas valve, springless diaphragm valve, tied diaphragm technology, uhp diaphragm valve, UHP valve applications, ultra high purity high pressure diaphragm valve, ultra high purity valve, VCR fitting valve

- No Comments

Ultra High Purity High Pressure Diaphragm Valve: A Critical Component in Advanced Industrial Applications

In the realm of high-tech industries such as semiconductor manufacturing, pharmaceuticals, and biotechnology, maintaining the utmost purity of gases and fluids is paramount. Contamination at even the microscopic level can lead to product failures, safety hazards, and significant financial losses. This is where the ultra high purity high pressure diaphragm valve comes into play. These specialized valves are engineered to handle extreme conditions while ensuring minimal particle generation and exceptional leak integrity. Designed for environments where purity levels exceed 99.999% and pressures can reach up to 4,500 psig, they represent the pinnacle of valve technology for critical processes.

The ultra high purity high pressure diaphragm valve is a type of sealed valve that uses a flexible diaphragm to isolate the process media from the valve’s actuating mechanism. This design prevents contamination from external sources and minimizes the risk of leaks. Unlike traditional ball or gate valves, diaphragm valves offer superior cleanliness, making them indispensable in ultra-high-purity (UHP) systems. As industries push the boundaries of miniaturization and precision, the demand for such valves continues to grow, driving innovations in materials and manufacturing techniques.

Design and Construction

The core of an ultra high purity high pressure diaphragm valve lies in its robust yet precise construction. Typically, these valves feature a body made from 316L VIM-VAR stainless steel, a vacuum induction melted and vacuum arc remelted alloy that provides exceptional corrosion resistance and low inclusion content. This material choice ensures that the valve can withstand aggressive chemicals and high pressures without degrading or introducing impurities.

The diaphragm itself is often crafted from elastomers like EPDM, PTFE, or metal alloys such as Elgiloy or Hastelloy, depending on the application’s requirements. In high-pressure models, multi-layer diaphragms are common to enhance durability and pressure-handling capabilities. The valve’s internal surfaces are electropolished to achieve a surface roughness of less than 10 Ra, reducing particle adhesion and facilitating easy cleaning.

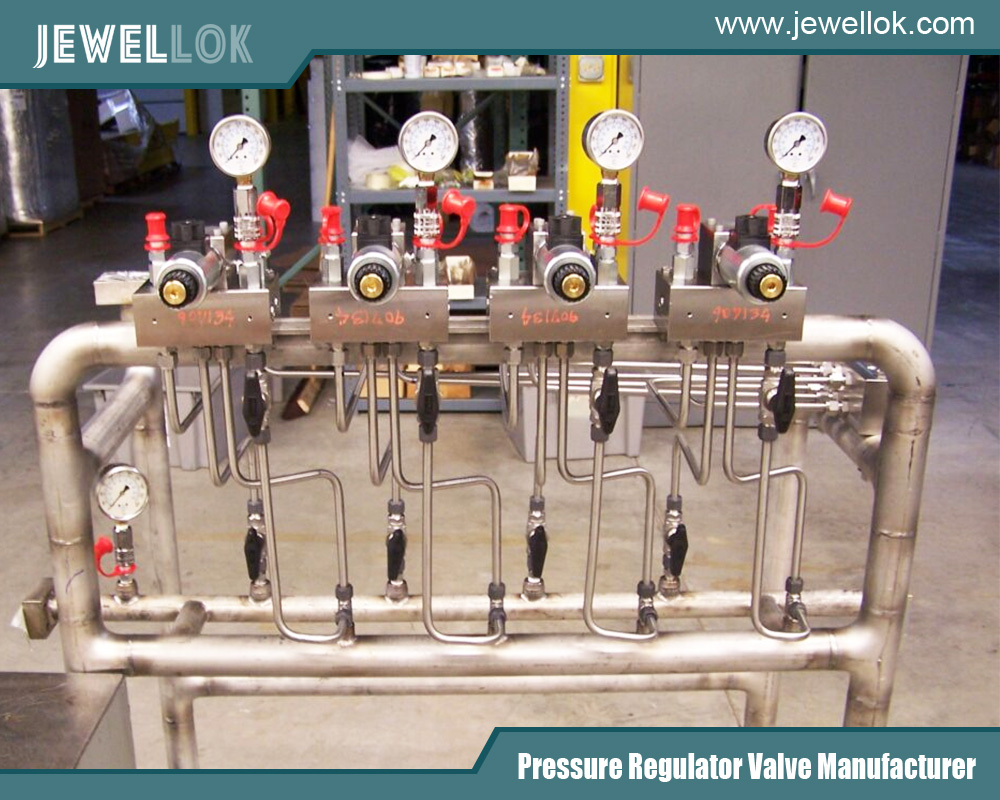

Actuation mechanisms vary: manual operators for precise control, pneumatic actuators for automated systems, or even springless designs to eliminate potential contamination sources. Low-pressure variants operate up to 150 psig, while high-pressure models can handle up to 3,500 psig or more. Flow paths are optimized for minimal dead space, ensuring complete purging and reducing the risk of trapped contaminants. Configurations include straight-pattern, angle-pattern, or modular surface-mount options, allowing integration into compact gas delivery systems.

Operating Principles

At its heart, the ultra high purity high pressure diaphragm valve operates on a simple yet effective principle: the diaphragm acts as a barrier that flexes to open or close the flow path. When the valve is closed, the diaphragm seals against a weir or seat in the valve body, creating a hermetic seal. Actuation—whether manual, pneumatic, or electric—applies force to compress or release the diaphragm.

In high-pressure scenarios, the valve must maintain integrity under significant stress. Advanced designs incorporate features like tied-diaphragm technology, where the diaphragm is mechanically linked to the stem, preventing over-extension and ensuring reliable cycling. Cycle life often exceeds 1 million operations, thanks to fatigue-resistant materials.

Purity is maintained through several mechanisms. The absence of sliding or rotating parts in the wetted area minimizes particle generation. Helium leak testing ensures rates below 1×10^-9 std cc/sec, far surpassing standard industrial valves. Additionally, these valves support in-situ cleaning processes like steam-in-place (SIP) or clean-in-place (CIP), crucial for maintaining UHP standards.

Applications in Key Industries

The versatility of ultra high purity high pressure diaphragm valves makes them essential across multiple sectors. In semiconductor fabrication, they control the flow of specialty gases like silane, arsine, and nitrogen in chemical vapor deposition (CVD) and etching processes. Here, even trace impurities can ruin wafer yields, so UHP valves are integrated into gas panels and delivery manifolds.

Pharmaceutical and biopharmaceutical industries rely on these valves for sterile processing. They handle high-purity water, buffers, and active pharmaceutical ingredients (APIs) under high pressure, ensuring compliance with regulations like USP <788> for particulate matter. In biotechnology, they facilitate cell culture media transfer without introducing endotoxins.

Other applications include photovoltaic manufacturing for solar cells, where pure gases are used in doping processes, and analytical instrumentation like gas chromatography, where precise flow control is needed. In aerospace and defense, they manage high-pressure fluids in propulsion systems, prioritizing reliability under extreme conditions.

Advantages Over Conventional Valves

Compared to bellows or needle valves, diaphragm valves offer distinct advantages in UHP high-pressure environments. Their sealed design eliminates stem packing, a common source of leaks and contamination. This results in lower maintenance needs and longer service intervals.

High-pressure capability without compromising purity is another key benefit. While ball valves might handle similar pressures, they often generate particles from ball-seat friction. Diaphragm valves, with their smooth, non-abrasive operation, produce negligible particulates, often below 0.1 particles per cubic foot.

Energy efficiency is enhanced through low actuation forces, reducing wear on pneumatic systems. Moreover, their compact size allows for dense installations in cleanrooms, optimizing space in high-cost facilities.

Maintenance and Installation Considerations

Proper installation is critical for optimal performance. Valves should be mounted in orientations that prevent media pooling, typically with the actuator upward. Welding connections, such as tube butt welds or VCR fittings, must be performed in inert atmospheres to avoid oxidation.

Maintenance involves regular diaphragm inspections and replacements, guided by cycle counts or pressure tests. Non-destructive testing like dye penetrant or ultrasonic methods can detect early failures. In UHP systems, valves are often baked out at high temperatures to remove adsorbed moisture and volatiles.

Training for personnel is essential, as improper handling can introduce contaminants. Cleanroom protocols, including double-bagging and nitrogen purging during storage, preserve valve integrity.

Future Trends and Innovations

As industries evolve, ultra high purity high pressure diaphragm valves are seeing advancements. Integration with IoT for real-time monitoring of pressure, flow, and leak rates is on the rise, enabling predictive maintenance. Materials research focuses on nanocomposites for diaphragms, offering higher strength-to-weight ratios.

Sustainability drives the development of valves with recyclable components and lower energy consumption. In quantum computing and nanotechnology, even higher purity levels are demanded, pushing valve designs toward atomic-level cleanliness.

Hybrid valves combining diaphragm with other sealing technologies are emerging for ultra-high-pressure applications beyond 5,000 psig. Standardization efforts, like SEMI guidelines, ensure interoperability across global supply chains.

Conclusion

The ultra high purity high pressure diaphragm valve stands as a testament to engineering excellence, bridging the gap between demanding industrial needs and uncompromising purity standards. Its role in enabling cutting-edge technologies cannot be overstated. As we advance into an era of smaller, faster, and cleaner processes, these valves will continue to evolve, safeguarding the integrity of our most critical systems. With their blend of durability, precision, and cleanliness, they are not just components but enablers of innovation.

For more about ultra high purity high pressure diaphragm valve: a critical component in advanced industrial applications, you can pay a visit to Jewellok at https://www.specialtygasregulator.com/product-category/ultra-high-purity-diaphragm-valves/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

Medical Oxygen Single Stage Manual Gas Changeover Manifold Panel High-Purity Two-Stage Manual Gas Manifold Gas Pressure Control Panels

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid