Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

High Pressure Hydrogen Gas Cylinder Pressure Regulator: A Technical Overview

- Pressure Regulator Valve Manufacturer

- CGA 350 hydrogen regulator, dual stage hydrogen pressure regulator, high flow hydrogen regulator, high pressure gas regulator for hydrogen, high pressure hydrogen gas cylinder pressure regulator, high pressure hydrogen regulator, hydrogen embrittlement in regulators, Hydrogen Fuel Cell Pressure Regulators, hydrogen fuel cell regulator, hydrogen gas cylinder regulator, hydrogen gas manifold system, hydrogen gas pressure regulator, hydrogen pipe valves and fittings, hydrogen pressure reducing valve, hydrogen regulator applications, hydrogen regulator maintenance, hydrogen regulator safety features, hydrogen regulator standards, hydrogen valve manifold, Hydrogen valve manufacturers, hydrogen valves and fittings, hydrogen vehicle pressure regulator, industrial hydrogen gas regulator, integrated hydrogen manifold regulator, lightweight hydrogen regulator, low pressure hydrogen regulator, pressure relief valve for hydrogen, single stage hydrogen regulator, ultra high purity hydrogen regulator

- No Comments

High Pressure Hydrogen Gas Cylinder Pressure Regulator: A Technical Overview

In the realm of gas handling and distribution, the high pressure hydrogen gas cylinder pressure regulator stands as a critical component, ensuring safe and efficient delivery of hydrogen from storage cylinders to end-use applications. Hydrogen, known for its high energy density and role in clean energy transitions, is typically stored in cylinders at pressures ranging from 200 to 700 bar (approximately 2,900 to 10,000 psi). These extreme pressures necessitate specialized regulators to reduce the gas to workable levels, often below 10 bar, while maintaining flow consistency and purity. This article delves into the technical aspects of these regulators, exploring their design, operation, types, materials, applications, safety features, and maintenance considerations.

The importance of high pressure hydrogen regulators cannot be overstated. Hydrogen’s flammability, low ignition energy, and potential for embrittlement in metals demand precise control to prevent leaks, explosions, or system failures. As industries shift toward hydrogen fuel cells, automotive propulsion, and industrial processes, understanding these devices becomes essential for engineers, technicians, and researchers alike.

Principles of Operation

At its core, a high pressure hydrogen gas cylinder pressure regulator functions as a pressure-reducing valve. It operates on the principle of balancing forces between inlet pressure, outlet pressure, and a reference mechanism, typically a spring or diaphragm. When hydrogen enters from the cylinder at high pressure, it pushes against a piston or diaphragm. This movement opens or closes a valve seat, modulating the flow to achieve the desired outlet pressure.

In a basic single-stage regulator, the reduction occurs in one step. The inlet pressure acts directly on the sensing element, and as the cylinder depletes, the outlet pressure may fluctuate slightly due to the decreasing inlet force. For more precise control, dual-stage regulators employ two sequential reduction stages. The first stage reduces the high cylinder pressure to an intermediate level (e.g., 100-200 bar), and the second stage further lowers it to the final output. This design minimizes variations, ensuring a stable delivery pressure even as the source pressure drops from full to near-empty states.

Flow dynamics play a key role. Regulators are rated by their maximum inlet pressure (often up to 3,000 psi or higher for hydrogen-specific models) and flow capacity, measured in standard cubic feet per hour (SCFH) or liters per minute. Hydrogen’s low molecular weight results in higher velocities compared to heavier gases, requiring regulators with larger orifices or specialized flow paths to avoid turbulence and pressure drops.

Types of Regulators

High pressure hydrogen regulators come in various configurations tailored to specific needs.

1. Single-Stage Regulators: These are simpler and more compact, ideal for applications where pressure stability is not critical, such as laboratory setups or short-duration uses. They connect directly to the cylinder via standard fittings like CGA 350 for hydrogen. However, they may exhibit a “droop” effect, where outlet pressure decreases under high flow demands.

2. Dual-Stage Regulators: Preferred for precision applications, these maintain constant output regardless of inlet variations. For instance, in fuel cell systems, a dual-stage unit can deliver hydrogen at 1-5 bar consistently from a 350-bar cylinder. Models often include chrome-plated brass or stainless steel bodies for corrosion resistance.

3. Ultra-High Purity Regulators: Designed for semiconductor manufacturing or analytical instruments, these feature electropolished surfaces and minimal dead volumes to prevent contamination. They handle pressures up to 3,000 psi while ensuring hydrogen purity exceeds 99.999%.

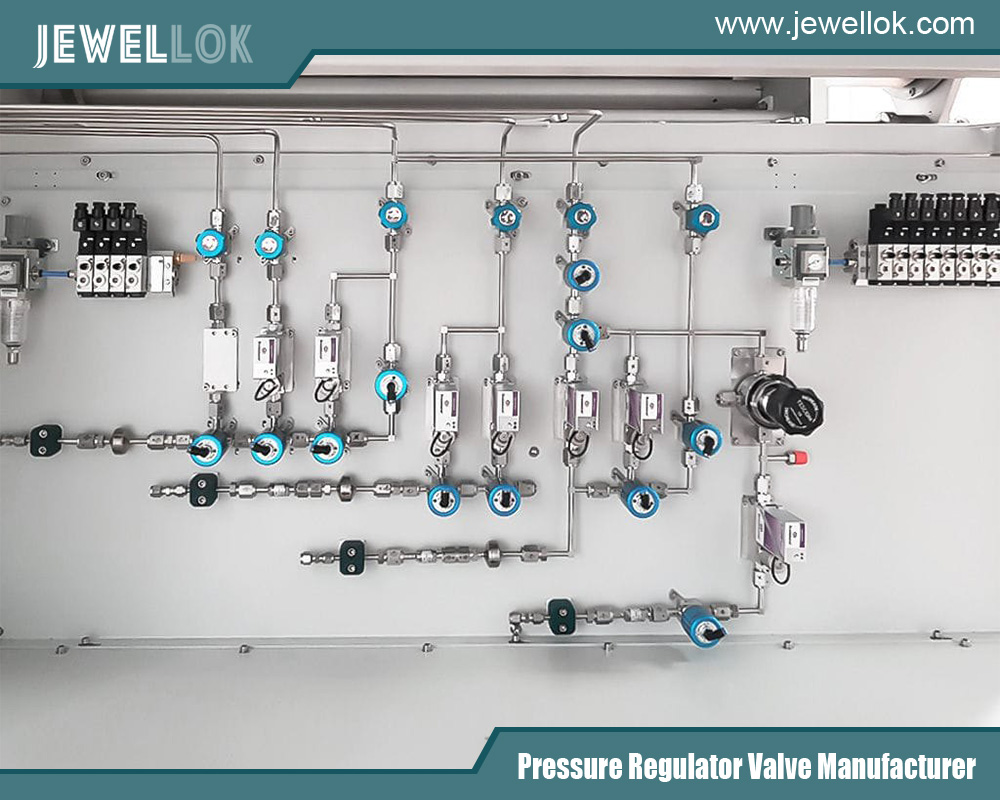

4. Integrated Manifold Regulators: Used in high-flow scenarios like vehicle refueling stations, these combine multiple stages with relief valves and filters in a single unit. Lightweight variants, weighing under 1 kg, are emerging for portable fuel cell drones or backup power systems.

Selection depends on factors like maximum operating pressure, flow rate, and environmental conditions. For example, cryogenic hydrogen applications might require regulators with insulated components to handle low temperatures.

Materials and Design Considerations

Hydrogen poses unique challenges due to its diffusivity and potential to cause hydrogen embrittlement—a phenomenon where atomic hydrogen penetrates metal lattices, leading to brittleness and cracking. To mitigate this, regulators use materials like 316L stainless steel, aluminum alloys, or titanium for wetted parts. Seals and diaphragms are often made from PTFE, Viton, or Kalrez to resist permeation and chemical attack.

Designs incorporate burst discs or pressure relief valves (PRVs) to vent excess pressure, complying with standards like CGA S-1.1. These PRDs activate at set thresholds, preventing cylinder rupture. Additionally, regulators may include particle filters to trap contaminants from the cylinder, ensuring clean gas delivery.

Thermal management is crucial; rapid depressurization can cause Joule-Thomson cooling, potentially freezing components. Advanced models feature heated elements or insulated housings. Ergonomics, such as easy-grip knobs for pressure adjustment, enhance usability in field operations.

Applications

The versatility of high pressure hydrogen regulators spans multiple sectors.

In fuel cell vehicles (FCVs), regulators step down tank pressures (up to 700 bar) to supply stacks at 1-2 bar. Integrated units combine regulation with solenoid valves for on-demand flow, optimizing efficiency and safety.

Industrial processes, such as metal hydride storage or chemical synthesis, rely on these devices for precise dosing. In welding and cutting, hydrogen regulators provide mixed gases at controlled pressures for oxy-hydrogen torches.

Renewable energy storage employs regulators in electrolysis systems, where produced hydrogen is compressed into cylinders and later regulated for power generation.

Aerospace and defense applications use lightweight, high-reliability regulators for propulsion systems in rockets or UAVs, where weight savings are paramount.

Emerging uses include hydrogen refueling infrastructure, where regulators handle ultra-high pressures during fast-fill operations, adhering to SAE J2601 protocols.

Safety Features and Standards

Safety is paramount in hydrogen handling. Regulators incorporate fail-safe mechanisms like automatic shut-off valves that close if downstream pressure exceeds limits. Overpressure protection via PRVs or rupture discs ensures compliance with ASME and ISO standards.

Leak detection is facilitated by bubble-tight seals and optional pressure gauges. Users must follow protocols for cylinder connection, avoiding cross-threading that could lead to leaks. Regular testing for embrittlement and seal integrity is recommended.

Global standards, including UN ECE R134 for vehicles and NFPA 2 for hydrogen systems, dictate design and testing. Regulators undergo burst tests at 4-5 times rated pressure and cycle testing for durability.

Maintenance and Best Practices

Proper maintenance extends regulator lifespan and ensures safety. Visual inspections for corrosion or damage should occur before each use. Annual servicing involves disassembly, cleaning, and replacement of seals.

Storage in dry, ventilated areas prevents moisture ingress, which could react with hydrogen. Calibration using certified gauges verifies accuracy.

Best practices include using dedicated hydrogen regulators to avoid cross-contamination and training personnel on emergency procedures, such as venting in case of overpressure.

Conclusion

The high pressure hydrogen gas cylinder pressure regulator exemplifies engineering ingenuity in managing one of the most challenging gases. From basic pressure reduction to advanced integrated systems, these devices enable the safe harnessing of hydrogen’s potential. As the hydrogen economy expands, innovations in materials, smart controls, and miniaturization will further enhance their performance. Understanding their technical nuances empowers stakeholders to deploy them effectively, paving the way for a sustainable energy future.

For more about high pressure hydrogen gas cylinder pressure regulator, you can pay a visit to Jewellok at https://www.specialtygasregulator.com/high-purity-gas-pressure-regulator/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

Ultra High Purity Pressure Gauge For Laboratory And Semiconductor JR Series

-

Stainless Steel Mini Elbow Mini Tee Mini Cross Mini Tribow Ultrahigh Purity Mini Butt Weld Fittings

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

Semi Automatic Gas Changeover Manifold System Manual Changeover Manifold Panel Single Stage Automatic Switchover Board

-

Bulk Specialty Gas Systems (BSGS) Gas Cabinets And Scrubber Tail Gas Treatment Cabinets For High Purity Bulk Specialty Gas Delivery

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR